Cleaning agent for metal slurry cylinder of 3D printer and preparation method of cleaning agent

A technology of 3D printers and metal pastes, applied in the direction of detergent compositions, detergent compounding agents, chemical instruments and methods, etc., can solve the problems of corrosion of the inner wall of the printer barrel, damage to instruments and equipment, etc., and achieve low cost and time-consuming cleaning Short, efficient and non-corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

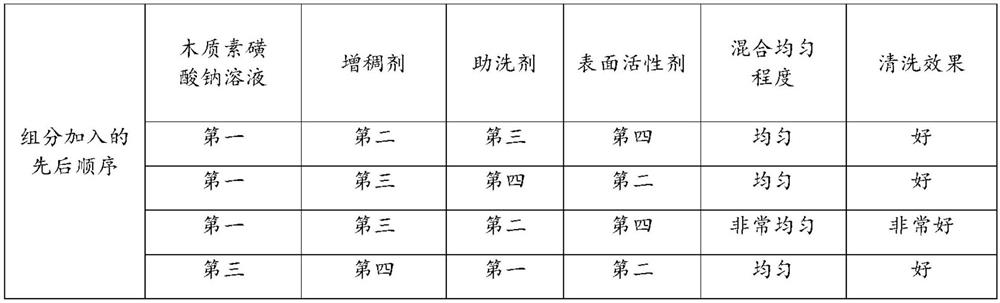

Embodiment 1

[0043] Prepare 20 g of sodium lignosulfonate and add 100 ml of deionized water to obtain a cleaning agent main solution. The solution was placed under a water bath at 80° C. for 1 hour under magnetic stirring, and then stood still for preparation. Prepare 10 g of glycerol and 7.5 g of agar, add 200 ml of deionized water to get thickener. Stir the thickener with a mechanical stirring device at a stirring speed of 800 rpm for 1 hour, and place the thickener in a water bath at 80° C. to keep warm to facilitate the combination of agar and glycerin, and then stand still for preparation. Add 2 g of sodium sulfate and 1 g of sodium citrate to 100 ml of deionized water, place it in a water bath at 80° C. and stir it magnetically for 1 h. Take 5g of octylphenol polyoxyethylene ether and 5g of fatty alcohol polyoxyethylene ether sodium sulfate and add it to 100ml of deionized water, place the main body of the obtained surfactant in a water bath at 50°C and carry out magnetic stirring f...

Embodiment 2

[0046]Prepare 20 g of sodium lignosulfonate and add 100 ml of deionized water to obtain a cleaning agent main solution. The solution was placed under a water bath at 80° C. for 1 hour under magnetic stirring, and then stood still for preparation. Prepare 10 g of glycerol and 7.5 g of agar, add 200 ml of deionized water to get thickener. Stir the thickener with a mechanical stirring device at a stirring speed of 800 rpm for 1 hour, and place the thickener in a water bath at 80° C. to keep warm to facilitate the combination of agar and glycerin, and then stand still for preparation. Add 2 g of sodium sulfate and 1 g of sodium citrate to 100 ml of deionized water, place it in a water bath at 80° C. and stir it magnetically for 1 h. Take 5g of octylphenol polyoxyethylene ether and 5g of fatty alcohol polyoxyethylene ether sodium sulfate and add it to 100ml of deionized water, place the main body of the obtained surfactant in a water bath at 50°C and carry out magnetic stirring fo...

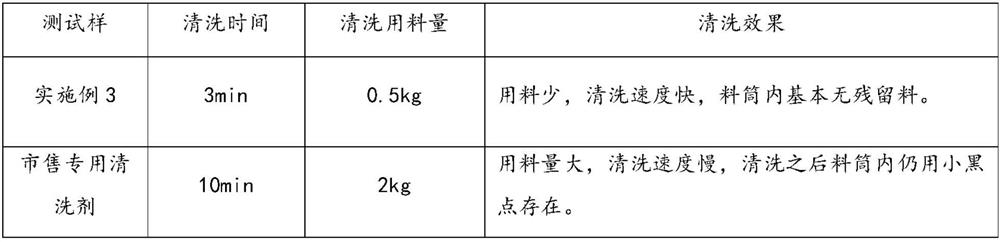

Embodiment 3

[0049] Prepare 20 g of sodium lignosulfonate and add 100 ml of deionized water to obtain a cleaning agent main solution. The solution was placed under a water bath at 80° C. for 1 hour under magnetic stirring, and then stood still for preparation. Prepare 10 g of glycerol and 7.5 g of agar, add 200 ml of deionized water to get thickener. Stir the thickener with a mechanical stirring device at a stirring speed of 800 rpm for 1 hour, and place the thickener in a water bath at 80° C. to keep warm to facilitate the combination of agar and glycerin, and then stand still for preparation. Add 2 g of sodium sulfate and 1 g of sodium citrate to 100 ml of deionized water, place it in a water bath at 80° C. and stir it magnetically for 1 h. Take 5g of octylphenol polyoxyethylene ether and 5g of fatty alcohol polyoxyethylene ether sodium sulfate and add it to 100ml of deionized water, place the main body of the obtained surfactant in a water bath at 50°C and carry out magnetic stirring f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com