Breathable anti-poison socks and manufacturing method thereof

A manufacturing method and breathable technology, which is applied in the direction of socks, pantyhose, textiles and paper, etc., can solve the problems that do not involve the manufacturing method of breathable anti-virus socks, and do not mention the bursting strength of anti-virus fabrics, etc., to achieve a large burst Strong, good anti-virus performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation of the first yarn of the present invention can refer to CN111733502A (the first yarn (carbon-doped yarn) and its production method), which is incorporated herein in its entirety. Acrylic refers to fibers spun from acrylonitrile-vinyl chloride (or vinylidene chloride) copolymers. The activated charcoal is fixed in the acrylic so that it does not fall off. Activated carbon can be ultrafine activated carbon. In some embodiments, the acrylonitrile-vinyl chloride fiber mixed with carbon fiber is made of acrylonitrile-vinyl chloride (or vinylidene chloride) copolymer fiber and activated carbon as raw materials, and using dimethylformamide as a solvent, using blending Made by spinning method. Activated carbon can be made from coconut shell charcoal, high temperature bamboo charcoal and charcoal through carbonization, activation, grinding and classification.

[0050] The linear density of the carbon-doped acrylic fiber may be 2.8-4.2 dtex, preferably 3.0-4.2 ...

Embodiment approach

[0064] According to one embodiment of the present invention, the manufacturing method of breathable anti-virus socks comprises the following specific steps:

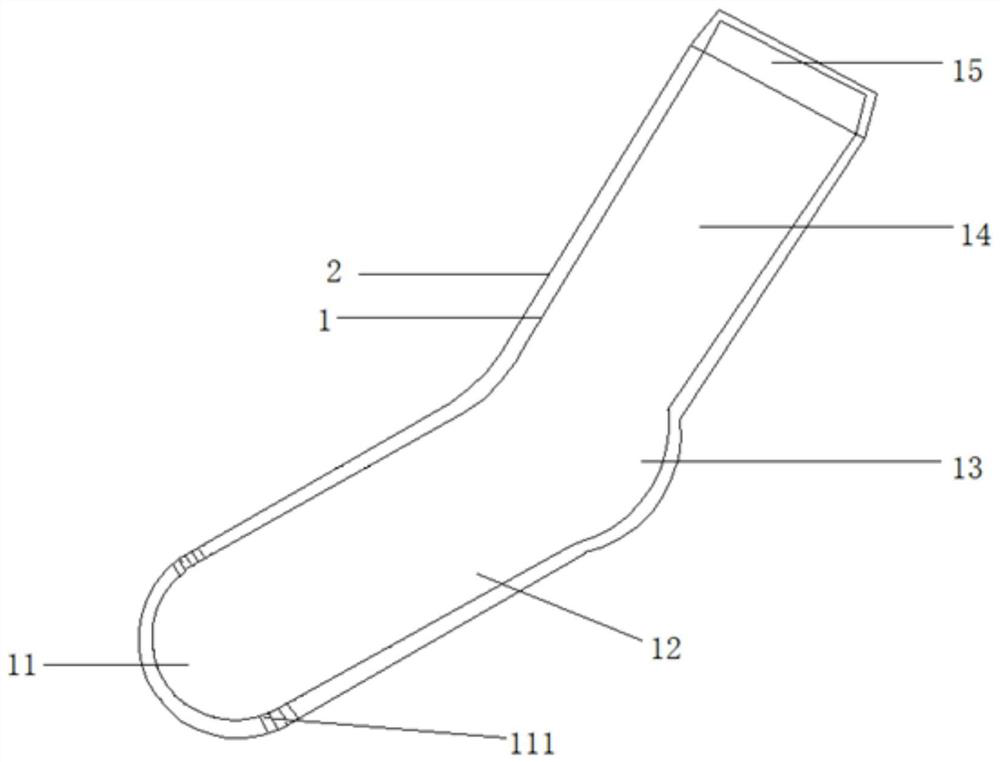

[0065] (1) Put the first yarn and the second yarn into the circular hosiery machine for double-layer continuous knitting. The knitting parts are the sock head-sock bottom-sock heel-sock tube-sock mouth- Sock opening-sock tube-sock heel-sock bottom-sock head; double-layer continuous knitted fabric is obtained; the sock head of the double-layer continuous knitted fabric has an opening;

[0066] Wherein, the quantity ratio of the first yarn and the second yarn is 1-3:1;

[0067] Wherein, the first yarn is a strand of carbon-doped fiber containing acrylic chloride fiber; the linear density of the first yarn is 45-74tex;

[0068] The second yarn has a spandex filament core yarn and other chemical fiber filament covering layers;

[0069] (2) The openings of the double-layer continuous braided fabric are sewed one by one to f...

preparation example

[0080] With reference to Example 1 of CN111733502A, a strand containing acrylonitrile-vinyl chloride fibers doped with carbon fibers was obtained. Details are as follows:

[0081] (1) Cleaning and carding: the selected acrylic-chlorinated fiber mixed with carbon fiber raw material is mixed, opened and cleaned by a cotton cleaning machine; the acrylic-chlorinated fiber-doped carbon fiber after cleaning is fed into the carding machine, Further remove impurities and non-spinnable fibers, and obtain raw sliver; wherein, in the acrylic fiber mixed with carbon fiber, the weight ratio of acrylic fiber and activated carbon is 85:15; the linear density of acrylic fiber mixed with carbon fiber is 3.6dtex, the linear density The density deviation is 9%, the breaking strength is 1.6cN / dtex, and the breaking elongation is 25%;

[0082] (2) Sliver making: the raw sliver is made into a uniform yarn line using a pressure roller and a coiling device, wherein the front roller speed is 112r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com