Polyoxy methylene fiber needle-punched non-woven geotechnical cloth and manufacturing method thereof

A technology of polyoxymethylene fiber and polyoxymethylene, which is applied in the direction of non-woven fabrics, textiles, and papermaking, and can solve the problems of small space for improving the performance of geotextiles, low strength of polypropylene fibers, and poor alkali corrosion resistance, etc. problems, to achieve the effect of high bursting resistance, strong anti-aging ability and high breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The polyoxymethylene filament with a diameter of 20 microns is crimped and cut off by a crimping machine to obtain curly short fibers, the length of the crimped short fibers is 65 mm, and the fiber crimp is 25%; the polyoxymethylene curly short fibers are coarsely opened Polyoxymethylene fiber needle-punched non-woven geotextiles are produced through processes such as fine opening, mixing, carding, web laying, needle punching, and finished product winding.

Embodiment 2

[0019] The polyoxymethylene filament with a diameter of 30 microns is crimped and cut off by a crimping machine to obtain curly short fibers, the length of the crimped short fibers is 65 mm, and the fiber crimp is 30%; the polyoxymethylene curly short fibers are coarsely opened Polyoxymethylene fiber needle-punched non-woven geotextiles are produced through processes such as fine opening, mixing, carding, web laying, needle punching, and finished product winding.

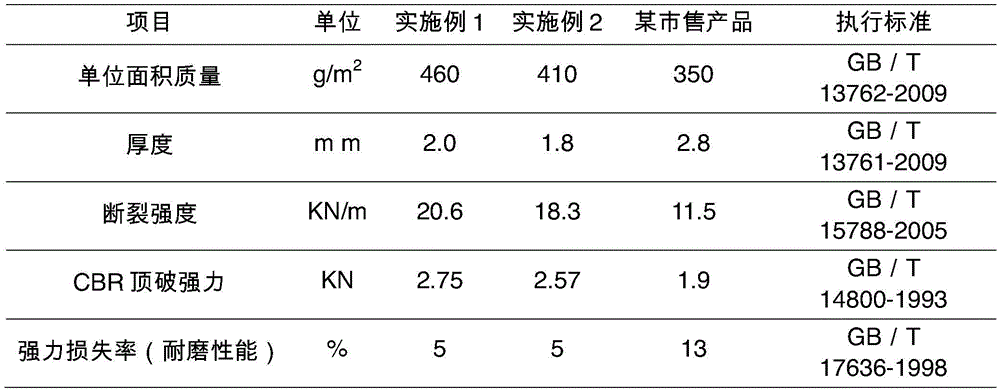

[0020] The obtained polyoxymethylene fiber needle-punched nonwoven geotextiles were subjected to performance tests with reference to various national standards, and a commercially available needle-punched nonwoven geotextile was used as a comparison. The test results are shown in the following table:

[0021]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com