Small-particle fertilizer centrifugal granulation device, granulation system and granulation process thereof

A technology of centrifugal granulation and small granules, which is applied in the direction of liquid separation into bead droplets, granulation in rotating discs/pots, etc., which can solve the problems of waste, clogging and cleaning, poor atomization uniformity, etc., and achieve easy ejection. , to avoid the effect of blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

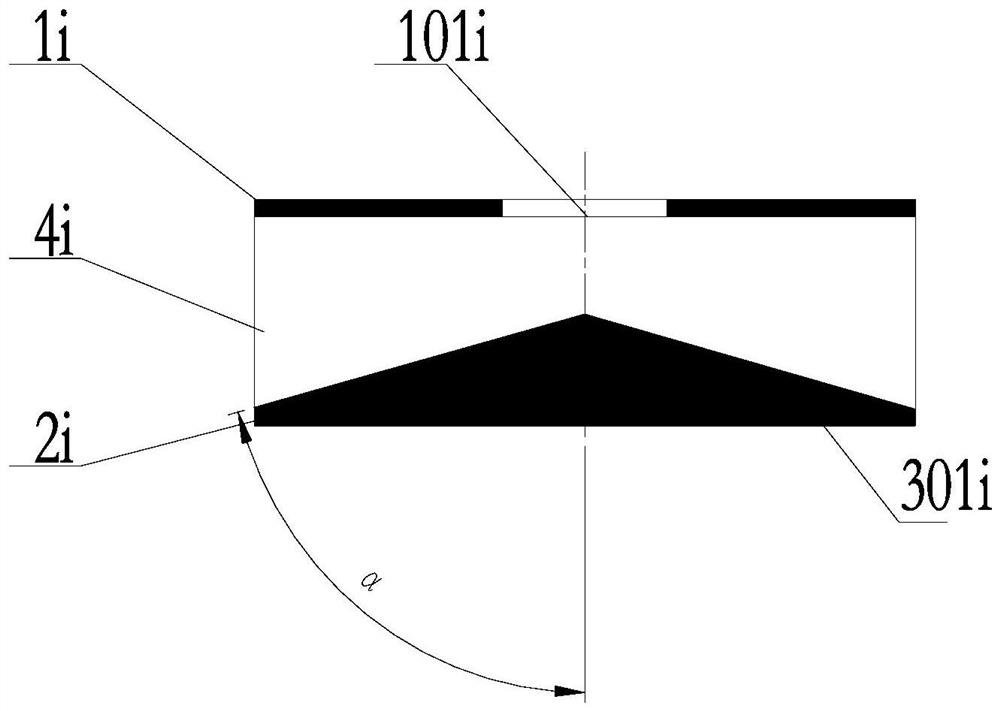

[0070] Such as figure 1 , figure 2 and Figure 9-Figure 22 As mentioned above, the present invention provides a fertilizer centrifugal granulation device, which includes an upper cover plate 1i and a lower cover plate 2i arranged at intervals up and down, an input port 101i for fertilizer melt is provided in the middle of the upper cover plate, and the input port is connected to the upper cover The interval space between the plate and the lower cover plate; the middle of the lower cover plate is driven and connected with the output shaft of the rotating motor, which is used to control the rotation of the granulation device around the central axis; it is characterized in that,

[0071] The inner surface of the lower cover plate located in the interval space is provided with a diversion platform 3i, the diversion platform is a rotationally symmetrical body around the central axis, and the surface of the diversion platform forms an angle α with the central axis. In this impleme...

Embodiment 2

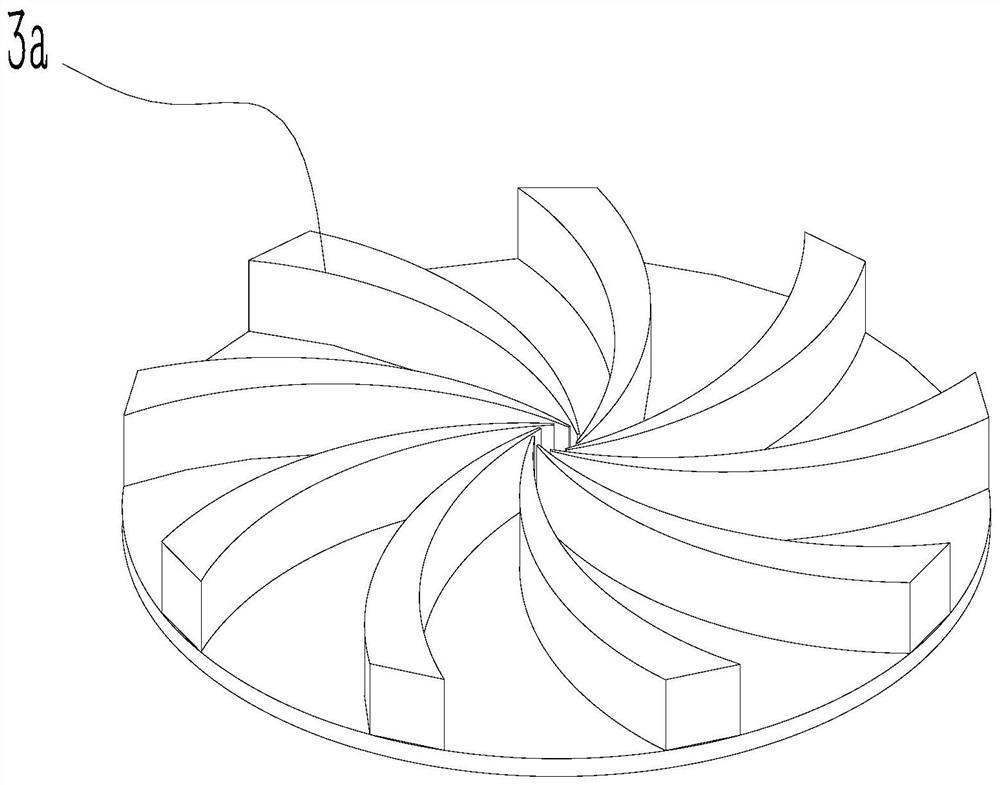

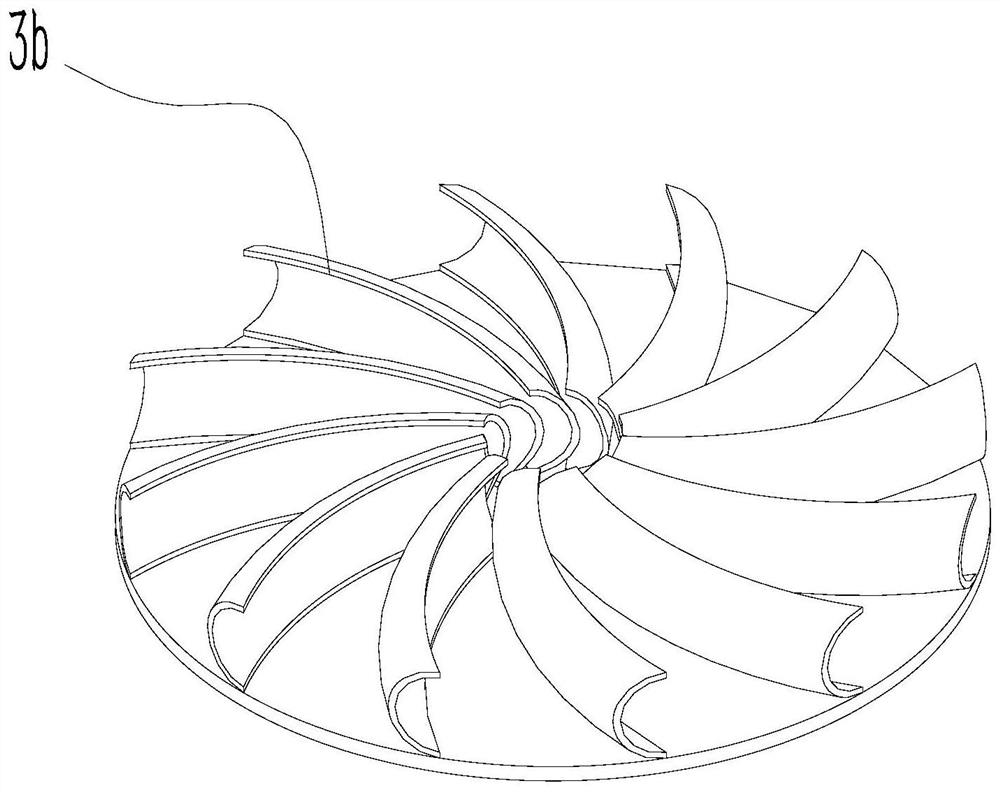

[0098] One of the embodiments of the present invention, such as figure 1 , image 3 and Figure 9-Figure 24 , the main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that the centrifugal granulation device is provided with a guide vane 3b, the normal cross-sectional shape of the guide vane along the extension direction is C-shaped, and the guide vane is arranged along the direction of the granulation device. The side in front of the direction of rotation is a torus, and the number of guide vanes is 8 to 24, and the preferred value is 12 in this embodiment.

Embodiment 3

[0100] One of the embodiments of the present invention, such as figure 1 , Figure 4 and Figure 9-Figure 24 , as shown, the main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that: between the upper cover plate and the lower cover plate, there are a plurality of internal deflectors 5c radially distributed around the middle, and the inner ends of the internal deflectors extend close to Central axis, the outer end of which extends away from the central axis; there are also a plurality of outer baffles 3c distributed circumferentially along the edge of the lower cover, the outer ends of the outer baffles are close to the edge of the lower cover, and the inner The ends extend toward the middle; the outer guide vanes are located on the outer periphery of the inner guide va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com