Method for dispersing and recovering nano material in water phase based on environmental response polymer

An environment-responsive, nano-material technology, applied in special compound water treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of low dispersibility of nano-materials, difficulty in separation and recovery, etc., and achieve improvement in difficult recovery, temperature control, etc. Reduced energy consumption and improved dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

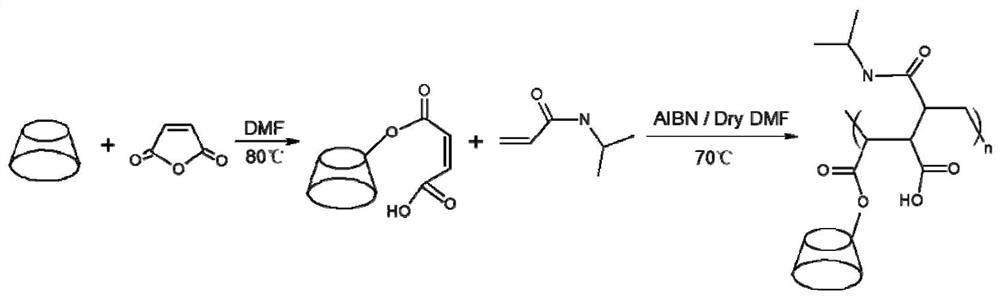

[0047] Specifically, the preparation method of the above-mentioned MAH-β-CD-co-PNIPAM includes the following operations:

[0048]a. Dissolve dry β-cyclodextrin (β-CD) and maleic anhydride in N,N-dimethylformamide (DMF), and stir the solution at 80°C for 12h to obtain modified maleic anhydride Cyclodextrin (MAH-β-CD). The obtained product MAH-β-CD was precipitated with chloroform and washed with acetone several times to obtain high-purity MAH-β-CD.

[0049] Wherein, the ratio of the amount of β-cyclodextrin to the reacting substance of maleic anhydride is 1:1.

[0050] b. MAH-β-CD and N-isopropylacrylamide (NIPAM) were dissolved in DMF, and azobisisobutyronitrile (AIBN) was added to obtain a suspension. The resulting suspension was placed in N 2 Under atmosphere and under anhydrous and oxygen-free conditions, the copolymerization reaction is carried out by stirring at 70° C. to 80° C. for 8 to 24 hours. After the end of the copolymerization reaction, the product mixed syste...

Embodiment 1

[0055] A kind of preparation method of environmental response (temperature sensitive) polymer collector:

[0056] a. Dissolve dry β-CD (β-cyclodextrin, 5.68g, 0.05mol) and maleic anhydride (0.49g, 0.05mol) in DMF (30mL), and stir the solution at 80°C for 12h, Maleic anhydride-modified cyclodextrin (MAH-β-CD) was obtained. The obtained product MAH-β-CD was precipitated with chloroform and washed with acetone several times to obtain high-purity MAH-β-CD.

[0057] b. MAH-β-CD (1.249 g, 1 mmol) and NIPAM (1.695 g, 15 mmol) were dissolved in 10 mL of DMF, and AIBN (0.044 g) was added to obtain a suspension. The resulting suspension was placed in N 2 The copolymerization reaction was carried out by stirring at 70° C. for 24 hours under an atmosphere. After the end of the copolymerization reaction, the product mixed system was obtained, and the solution of the obtained product mixed system was poured into a 2000Da dialysis bag for two days of dialysis, and then freeze-dried to obt...

Embodiment 2

[0059] A kind of preparation method of environmental response (temperature sensitive) polymer collector:

[0060] MAH-β-CD was prepared by the method described in step a in Example 1.

[0061] MAH-β-CD (1.249 g, 1 mmol) and NIPAM (1.13 g, 10 mmol) were dissolved in 10 mL of DMF, and AIBN (0.035 g) was added to obtain a suspension. The resulting suspension was placed in N 2 The copolymerization reaction was carried out by stirring at 70° C. for 24 hours under an atmosphere. After the end of the copolymerization reaction, the product mixed system was obtained, and the solution of the obtained product mixed system was poured into a 2000Da dialysis bag for two days of dialysis, and then freeze-dried to obtain MAH-β-CD-co-PNIPAM, that is, Environmentally responsive (temperature sensitive) polymer collector.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com