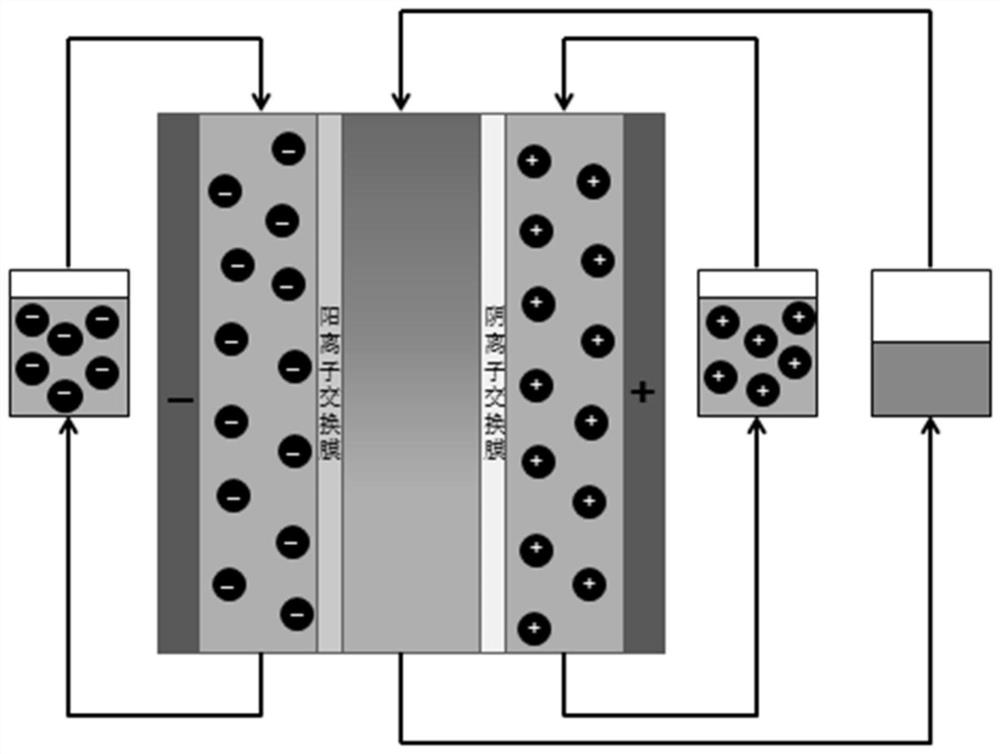

Method for purifying iodized salt-containing wastewater by using flowing electrode capacitive deionization device

A technology of capacitive deionization and flowing electrodes, which is applied in the field of capacitive deionization devices of flowing electrodes and cathode flowing electrode solution, can solve the problem of difficult to ensure stable, long-term and high-efficiency operation of the reactor, low charge transfer efficiency of collectors and flowing electrodes, Eliminate problems such as increased viscosity of the flow electrode, achieve high stability, improve desalination performance, and improve the effect of charge transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for purifying iodine-containing salt wastewater by using a flowing electrode capacitive deionization device, using the flowing electrode capacitive deionization device to perform adsorption treatment on the iodine-containing salt wastewater, comprising the following steps:

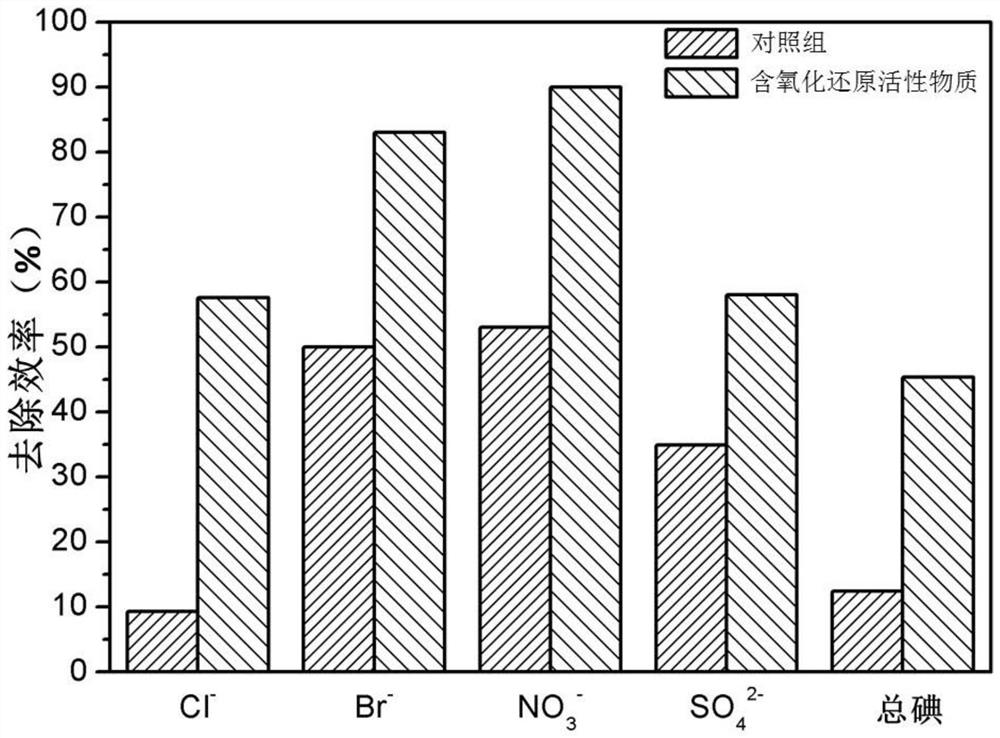

[0030] With a flow rate of 25mL / min, 50mL iodized salt wastewater (1000mg / L Cl - , 100mg / L Br - , 100mg / LNO 3 - , 100mg / L SO 4 2- , 10mg / L I - ) is pumped into the water inlet chamber through the water inlet pipe and circulates in the water inlet chamber. The flow rate is 50mL / min. After the conductivity is stable, power on to control the voltage between the anode flow electrode chamber and the cathode flow electrode chamber to 1.2V, that is, apply a constant voltage of 1.2V to the flow electrode capacitive deionization device to enter the adsorption stage. , start to desalination, a total of 30min, to complete the purification of iodine-containing salt wastewater.

[0031] Control g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com