Method for separating and purifying ganoderma lucidum beta-glucan oligosaccharide

A technology for separation and purification of glucooligosaccharides, which is applied in the field of natural medicinal chemistry, can solve problems such as separation and purification difficulties, and achieve the effects of good purity, high yield, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

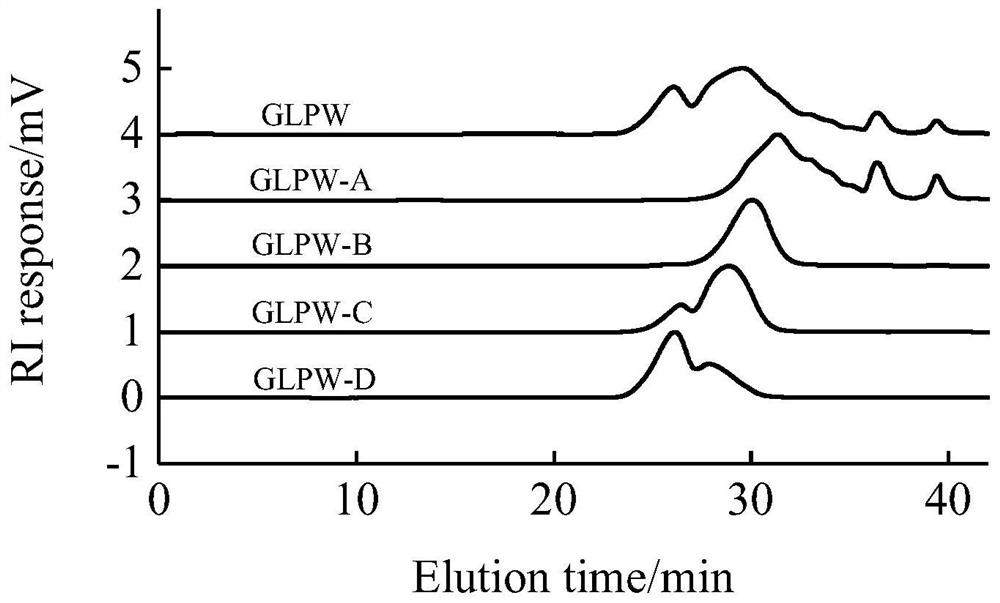

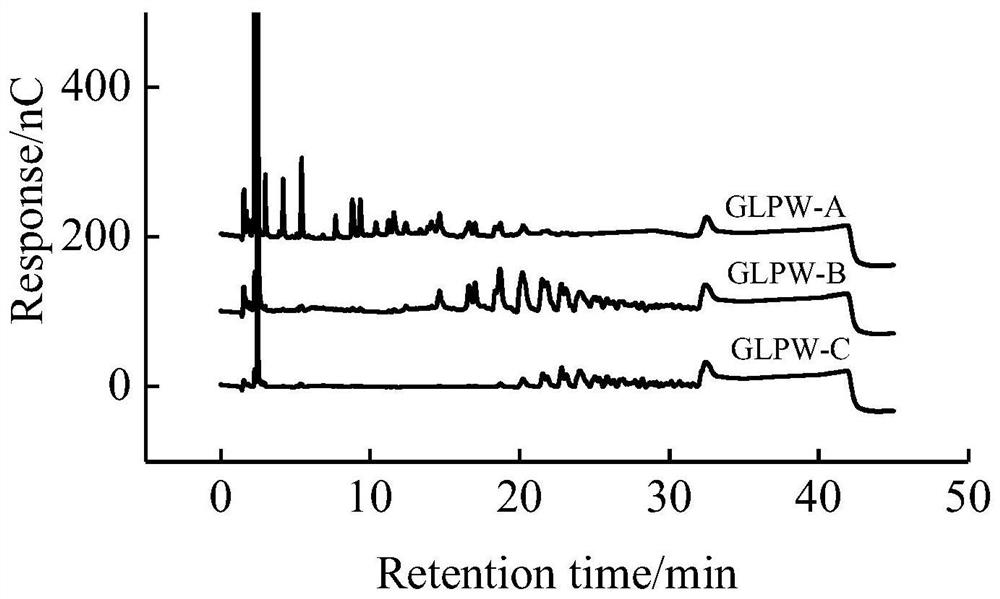

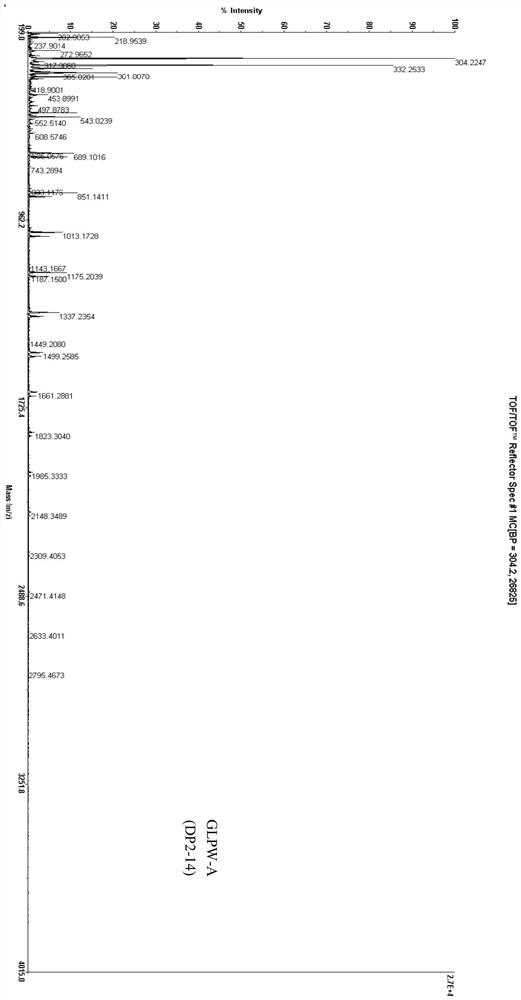

[0027] Example 1: Gradual alcohol precipitation separation and purification of Ganoderma lucidum β-oligosaccharide

[0028] Weigh 300 mg of Ganoderma lucidum β-oligosaccharide GLPW, add 10 mL of distilled water to prepare a 30 mg / mL solution of Ganoderma lucidum β-oligosaccharide, and stir well until dissolved.

[0029] Gradual alcohol precipitation separation of Ganoderma lucidum β-gluco-oligosaccharide GLPW: slowly add 90 mL of absolute ethanol to the solution until the final concentration of ethanol is 90% (v / v), stir well, let stand at 4°C for 4 hours, and collect by centrifugation The supernatant was washed by adding 50 mL of 90% (v / v) ethanol to the precipitate, and the supernatant was collected by centrifugation. After repeating 3 times, the supernatant was combined and concentrated under reduced pressure to remove the ethanol to obtain the GLPW-A fraction, which was freeze-dried. Add 10 mL of deionized water to the above-mentioned precipitation, fully stir until it is ...

Embodiment 2

[0030] Example 2: Gradual alcohol precipitation separation and purification of Ganoderma lucidum β-oligosaccharide

[0031] Weigh 500 mg of Ganoderma lucidum β-oligosaccharide GLPW, add 10 mL of distilled water to prepare a 50 mg / mL solution of Ganoderma lucidum β-oligosaccharide, and stir well until dissolved.

[0032] Gradual alcohol precipitation separation of Ganoderma lucidum β-gluco-oligosaccharide GLPW: slowly add 90 mL of absolute ethanol to the solution until the final concentration of ethanol is 90% (v / v), stir well, let stand at 4°C for 4 hours, and collect by centrifugation The supernatant was washed by adding 50 mL of 90% (v / v) ethanol to the precipitate, and the supernatant was collected by centrifugation and repeated 3 times. Add 10 mL of deionized water to the above-mentioned precipitation, stir fully until completely dissolved, slowly add 57 mL of absolute ethanol to the solution until the final concentration of ethanol is 85% (v / v), stir well and let stand at...

Embodiment 3

[0033] Example 3: Gradual alcohol precipitation separation and purification of Ganoderma lucidum β-oligosaccharide

[0034] Weigh 400 mg of Ganoderma lucidum β-oligosaccharide GLPW, add 10 mL of distilled water to prepare a 40 mg / mL solution of Ganoderma lucidum β-oligosaccharide, and stir well until dissolved.

[0035] Gradual alcohol precipitation and separation of Ganoderma β-oligosaccharide GLPW: slowly add 90 mL of absolute ethanol to the β-glucose oligosaccharide solution until the final concentration of ethanol is 90% (v / v), stir well and then keep it at 4°C Set aside for 4 h, collect the supernatant by centrifugation, wash the precipitate with 50 mL of 90% (v / v) ethanol, and repeat the centrifugation for 3 times, then combine the supernatant, concentrate under reduced pressure to remove the ethanol to obtain the GLPW-A fraction, and freeze-dry. Add 10 mL of deionized water to the above-mentioned precipitation, stir fully until completely dissolved, slowly add 57 mL of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com