Binder for back electrode silver paste and preparation method thereof

A backside electrode and binder technology, applied in the direction of adhesives, binder types, polysaccharide binders, etc., can solve the problems of insufficient photoelectric conversion rate of batteries and weak adhesion with silicon plates, etc., to achieve strong adhesion, Good adaptability and high light conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0024] According to a preferred embodiment of the present invention, the binder for the back electrode silver paste includes the following components in parts by weight: 3-5 parts of gum arabic, 2-4 parts of alginate, 0.4-1 part of squash gum, 0.2-0.4 parts of castor oil, 0.2-0.5 parts of carboxymethyl cellulose, 1-3 parts of sodium lauryl sulfate, 20 parts of water; and the castor oil, carboxymethyl cellulose and sodium lauryl sulfate The weight ratio is 0.24-0.3:0.35-0.4:1.

[0025] The second aspect of the present invention provides a kind of preparation method of described back electrode silver paste binder, and this method comprises:

[0026] (1) Gum Arabic, alginate, and safflower gum are mixed and ground, and dissolved in part of water to form a binder solution;

[0027] (2) The remaining water and sodium lauryl sulfate are mixed for the first time, then castor oil and carboxymethyl cellulose are added for the second mixing to obtain the mixture;

[0028] (3) Stir the...

Embodiment 1

[0042] (1) Gum Arabic, alginate, and safflower gum are mixed and ground, and dissolved in part of water to form a binder solution;

[0043] (2) first mixing the remaining water and sodium lauryl sulfate, then adding castor oil and mixing, then adding carboxymethyl cellulose and mixing to obtain the mixture;

[0044] (3) Stir the binder solution and the mixture to obtain a binder.

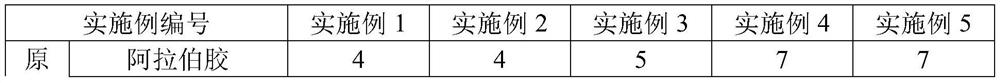

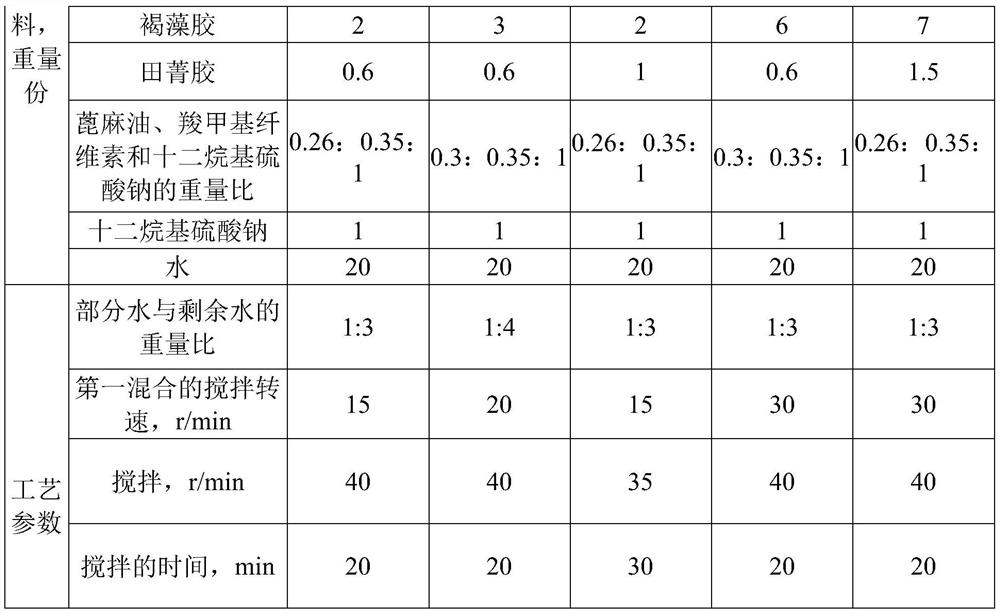

[0045] The dosage and process parameters of the above-mentioned raw materials are shown in Table 1.

[0046] The bonding strength of the obtained adhesive was measured according to GB / T 1742-1979, as shown in Table 2. According to the method of CN105469854B, a polycrystalline silicon solar cell was fabricated, and its photoelectric conversion efficiency was measured, as shown in Table 2.

Embodiment 2-3

[0048] According to the method of Example 1, the difference is that the amount of raw materials shown in Table 1 and the process parameters are used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com