A heat-insulating packaging bag and its preparation method and application

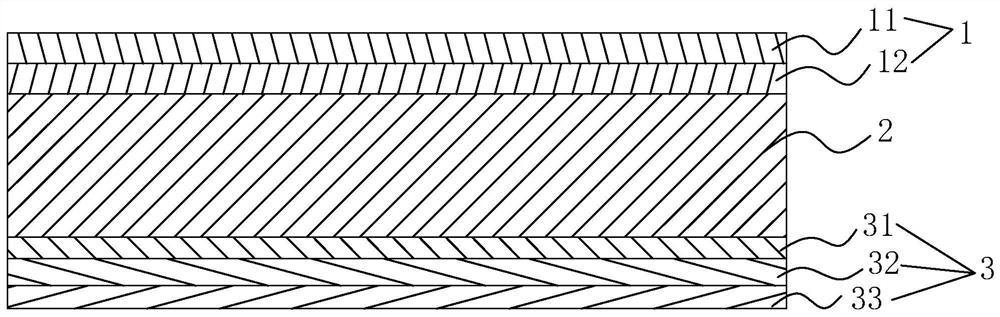

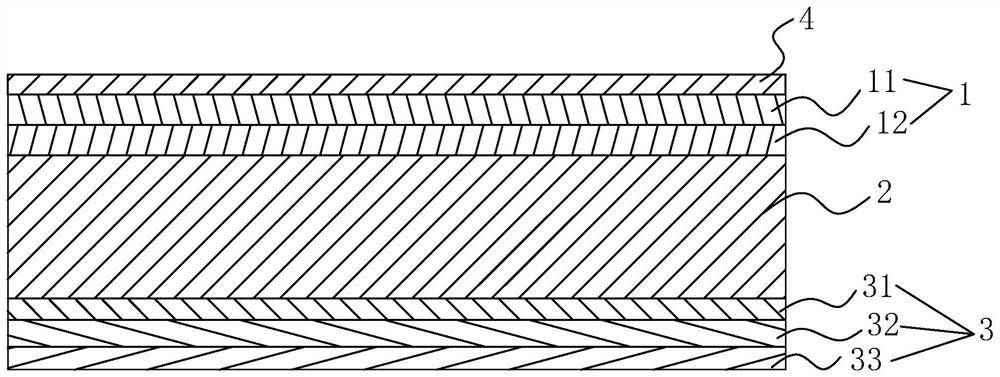

A packaging bag, hot-pressing temperature technology, applied in the field of heat-insulating packaging bags and their preparation, can solve problems such as poor heat insulation performance, explosion-proof performance and cushioning performance, scratches or damage to packaging bag products, and packaging bag damage, etc., to achieve Improve barrier performance and tear strength, excellent infrared absorption function, excellent heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

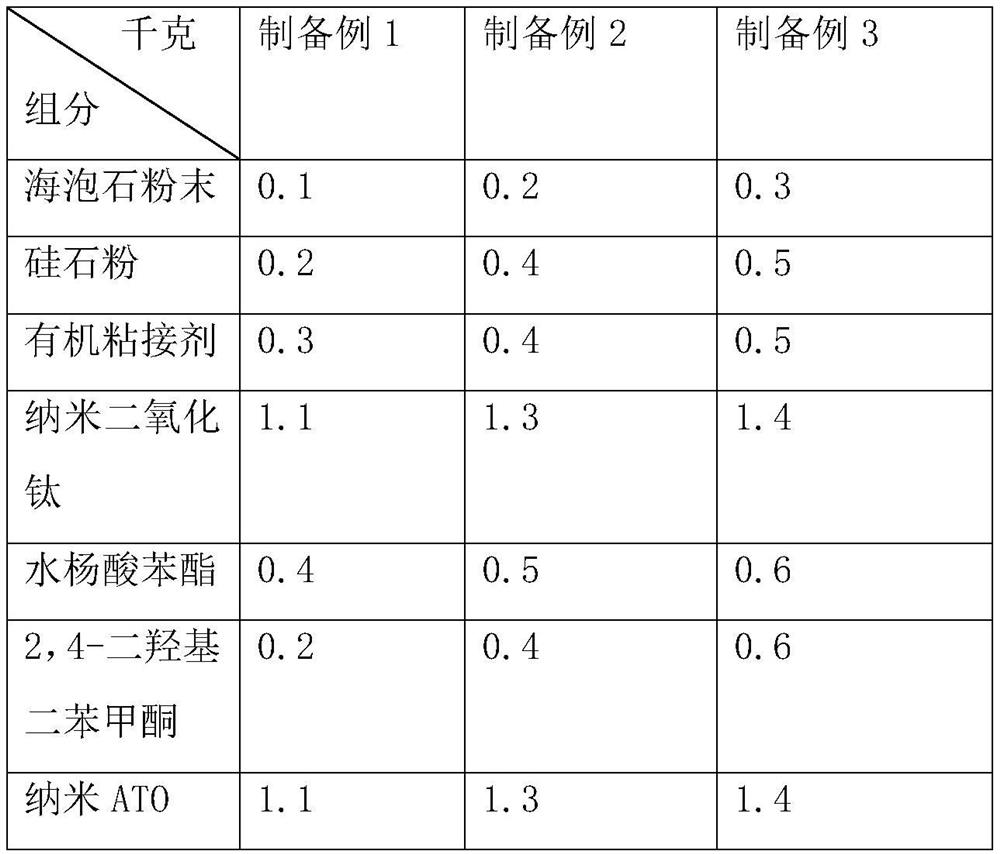

preparation example 1-3

[0044] In Preparation Example 1-3, the polyurethane adhesive is selected from the polyurethane adhesive sold by Jining Huakai Resin Co., Ltd. with the brand name HK-7051, and the acrylate emulsion adhesive is selected from Changsha Huihua Adhesive Technology Co., Ltd. The model of the acrylic emulsion adhesive is HH-610BN9. The silica powder is selected from the silica powder with the product number 003 sold by Lingshou County Jiahao Mineral Powder Factory. The sepiolite powder is selected from Lingshou County Kaiqi Mineral Products Processing Factory The sold sepiolite powder is 13, nano-ATO is selected from the nano-ATO of the model ATO sold by Zhengzhou Xinhao Chemical Products Co., Ltd., and phenyl salicylate is selected from the product number 006 sold by Zhengzhou Huidong Chemical Products Co., Ltd. of phenyl salicylate.

[0045] Preparation Example 1-3: According to the raw material ratio in Table 1, the following components were mixed and stirred to make a transparent ...

preparation example 2

[0048] Preparation Example 2: According to the raw material ratio in Table 1, the following components were mixed and stirred to make a transparent heat-insulating coating: 0.2kg sepiolite powder, 0.4kg silica powder, 0.4kg organic binder, 1.3kg nano-titanium dioxide , 0.5kg phenyl salicylate, 0.4kg 2,4-dihydroxybenzophenone, 1.3kg nano-ATO, the average particle diameter of sepiolite powder and silica powder is 40 μm, and the organic adhesive is acrylate emulsion glue adhesive.

preparation example 3

[0049] Preparation Example 3: According to the raw material ratio in Table 1, the following components were mixed and stirred to make a transparent heat-insulating coating: 0.3kg sepiolite powder, 0.5kg silica powder, 0.5kg organic binder, 1.4kg nano-titanium dioxide , 0.6kg of phenyl salicylate, 0.6kg of 2,4-dihydroxybenzophenone, 1.4kg of nano-ATO, sepiolite powder and silica powder with a particle size of 50 μm, and the organic adhesive is an acrylate emulsion adhesive .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com