Structural layout of subway stations and intervals and mechanized rapid construction method of structural layout

A technology for subway stations and construction methods, which is used in earth-moving drilling, underground chambers, and shaft equipment, etc., can solve problems such as hidden dangers of safe operation, obvious weather effects, and impact on people flow, so as to reduce the number of arrivals, dismantling and installation, economical and The effect of obvious social benefits and reduction of the amount of abandoned temporary works

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

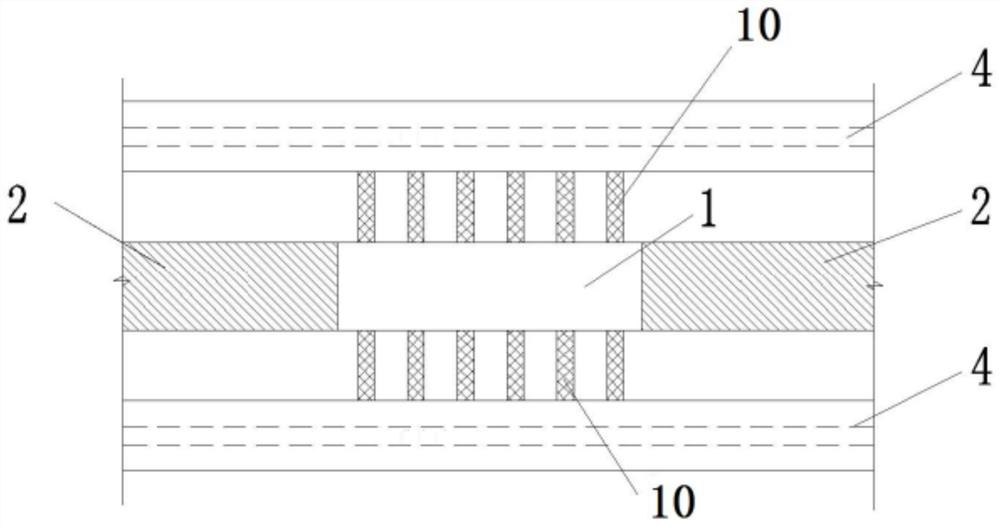

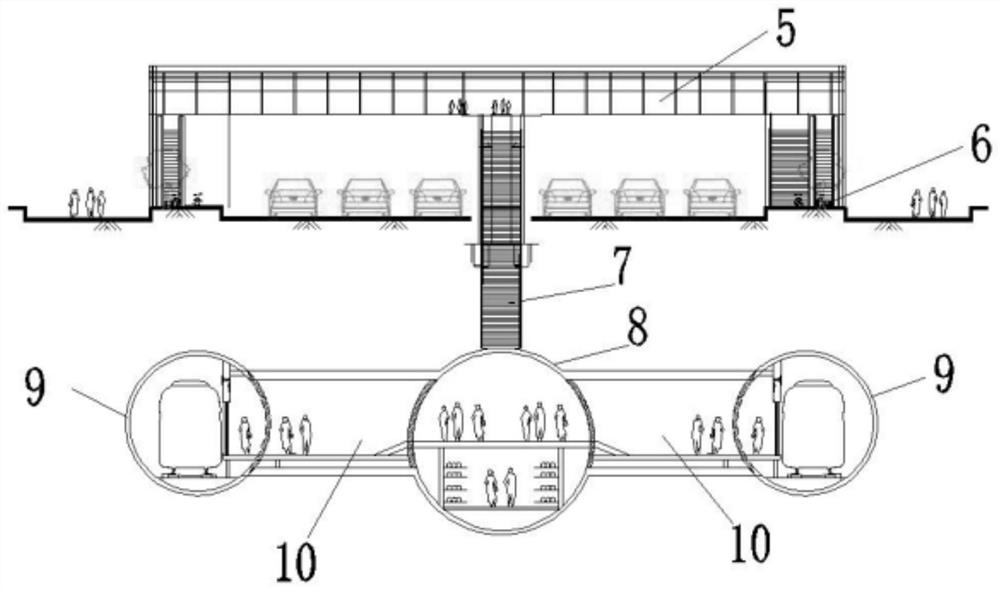

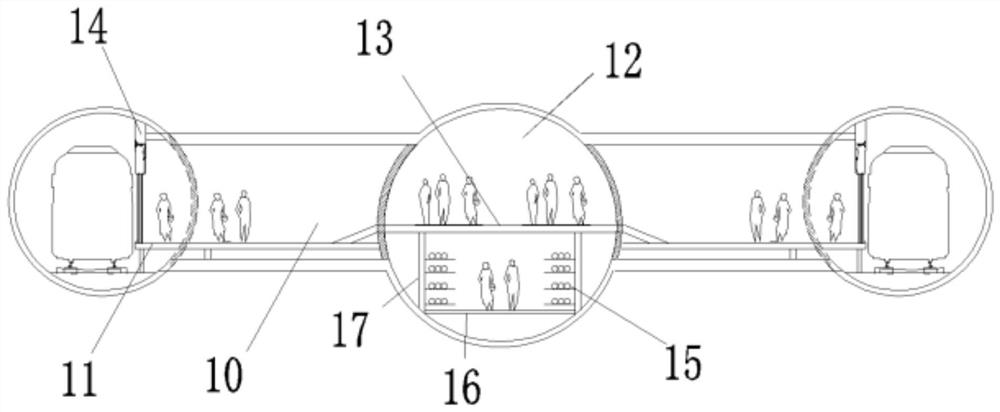

[0066] A structural layout of subway stations and intervals, including three parallel interval tunnel structures 4 and stations with several longitudinal lengths, wherein the middle is a station tunnel 8, and both sides are interval tunnels 9, such as figure 1 As shown, the interval tunnel 9 is a train track area, and the station tunnel 8 and the interval tunnel 9 are connected by a connecting passage 10; the station includes an intermediate platform area 1, and the two ends of the intermediate platform area 1 extend into an end living room and an equipment area 2; where the station The tunnel 8 is divided into upper and lower layers by a transverse partition 13 to form a large-section tunnel in the middle. A pipe gallery work platform 16 is provided at the bottom of the station tunnel 8, and vertical support walls 17 are provided on both sides of the pipe gallery work platform 16 for vertical support. The upper end of the wall 17 is connected with the transverse partition 13 t...

Embodiment 2

[0068] A mechanized rapid construction method for the structural layout of subway stations and intervals, comprising the following steps:

[0069] ① On the subway line, according to the project planning, ground surrounding environment and hydrogeological conditions, select the starting shaft or station as the starting point of the tunnel boring machine, and use the tunnel boring machine to construct the underground tunnel to avoid the construction of stations with bad ground environment; For sites with harsh ground conditions, tunnel boring equipment is used to construct underground tunnel structures, which double as stations and sections to avoid harsh ground conditions;

[0070] ②Adopt tunnel boring machines that meet the requirements of tunnel boundaries and building boundaries of station platforms and halls, and construct three sections and stations of several longitudinal lengths at one time.

[0071] The tunnel boring machine is selected to meet the subway limit regulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com