Electrolyte additive for high-voltage lithium ion battery and application of electrolyte additive

An electrolyte additive, a technology for lithium ion batteries, applied in the field of lithium ion batteries, can solve problems such as poor cycle performance, and achieve the effects of slowing down the formation of spinel phase, easy preparation, and alleviating voltage decay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Weigh a certain amount of β-carotene in an argon atmosphere glove box and put it in a transparent glass bottle, and add a certain amount of reference ternary electrolyte (1.0M LiPF6 in EC:DMC:EMC=1: 1:1Vol%), stirred overnight to fully dissolve the additive.

[0026] 2) Take the solution in 1) and filter it with a 0.22 μm filter membrane to obtain a clear 0.5 wt% electrolyte solution.

[0027] 3) A battery is assembled using the electrolyte.

[0028] At the same time, as a comparison, a battery was assembled using a reference electrolyte without additives as a comparative example.

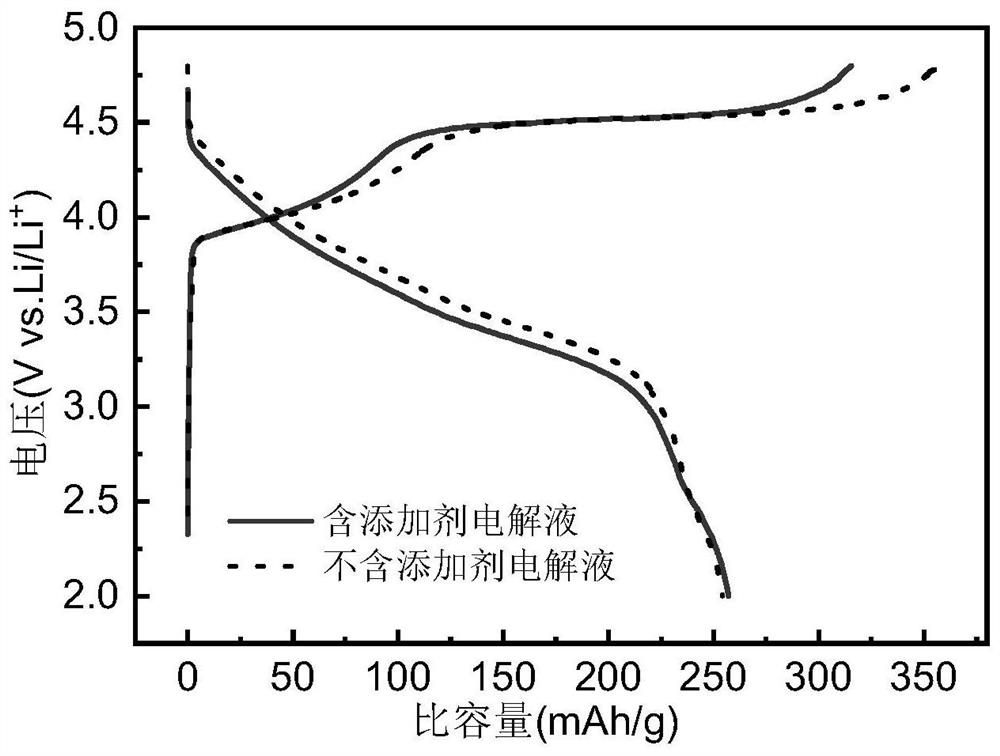

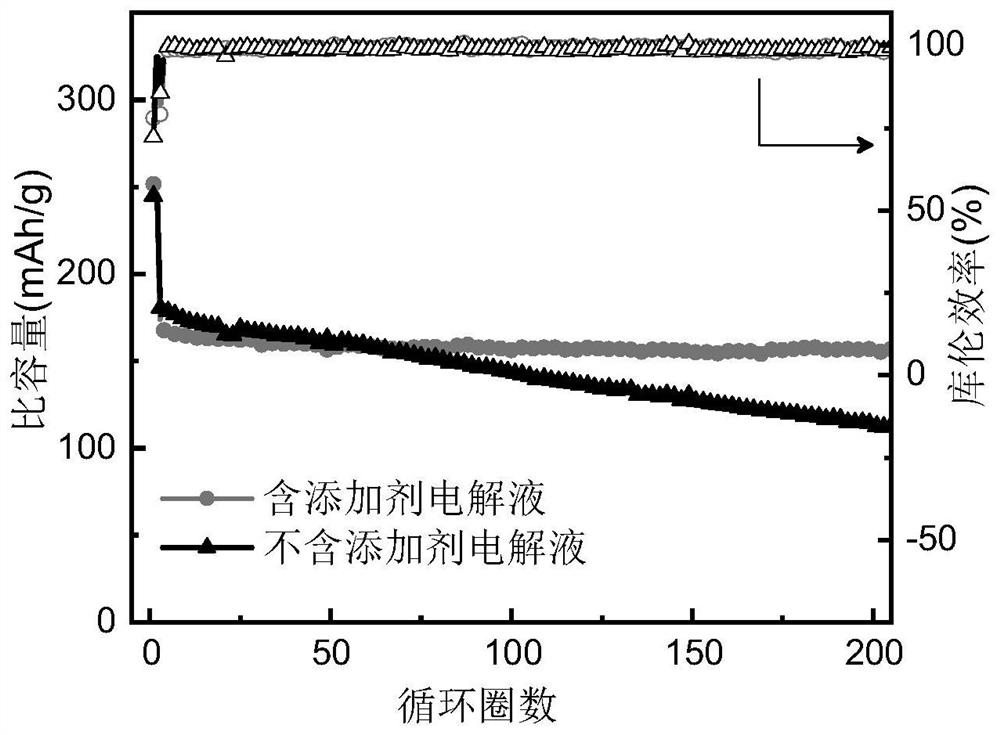

[0029] Test results such as figure 1 As shown, the first-cycle charge specific capacity of the high-voltage electrolyte containing β-carotene additives is 315mAh / g, the discharge specific capacity is 257mAh / g, and the first-cycle Coulombic efficiency is 81.6%. The first cycle charge specific capacity of the battery without additives is 356mAh / g, the discharge specific capacity is 254mA...

Embodiment 2

[0032] 1) Weigh a certain amount of β-carotene in an argon atmosphere glove box and put it in a transparent glass bottle, and add a certain amount of reference ternary electrolyte (1.0M LiPF6 in EC:DMC:EMC=1: 1:1Vol%), stirred overnight to fully dissolve the additive.

[0033] 2) Take the solution in 1) and filter it with a 0.22 μm filter membrane to obtain a clear 0.1 wt% electrolyte solution.

[0034] 3) Assemble a battery with the electrolyte.

[0035] Test results: when the current density is 20mA / g, the first-cycle charge specific capacity is 319mAh / g, the discharge specific capacity is 243mAh / g, and the first-cycle coulombic efficiency is 76.2%. Then, after 100 cycles at a current density of 200mA / g, the discharge capacity of the battery is 164mAh / g, and the capacity retention rate reaches 92.7%.

Embodiment 3

[0037] 1) Weigh a certain amount of β-carotene in an argon atmosphere glove box and put it in a transparent glass bottle, and add a certain amount of reference ternary electrolyte (1.0M LiPF6 in EC:DMC:EMC=1: 1:1Vol%), stirred overnight to fully dissolve the additive.

[0038] 2) Take the solution in 1) and filter it with a 0.22 μm filter membrane to obtain a clear 5.0 wt % electrolyte solution.

[0039] 3) Assemble a battery with the electrolyte.

[0040] Test results: when the current density is 20mA / g, the first-cycle charge specific capacity is 305mAh / g, the discharge specific capacity is 214mAh / g, and the first-cycle coulombic efficiency is 70.1%. Then, after 100 cycles at a current density of 200mA / g, the discharge capacity of the battery is 144mAh / g, and the capacity retention rate reaches 97.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com