Steel-inlaid blade and welding surface processing method and preparation method thereof

A processing method and welding surface technology, applied in metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve the problems of cracks, virtual welding, cracks and other problems of insert steel blades, so as to improve quality, service life and high efficiency , the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

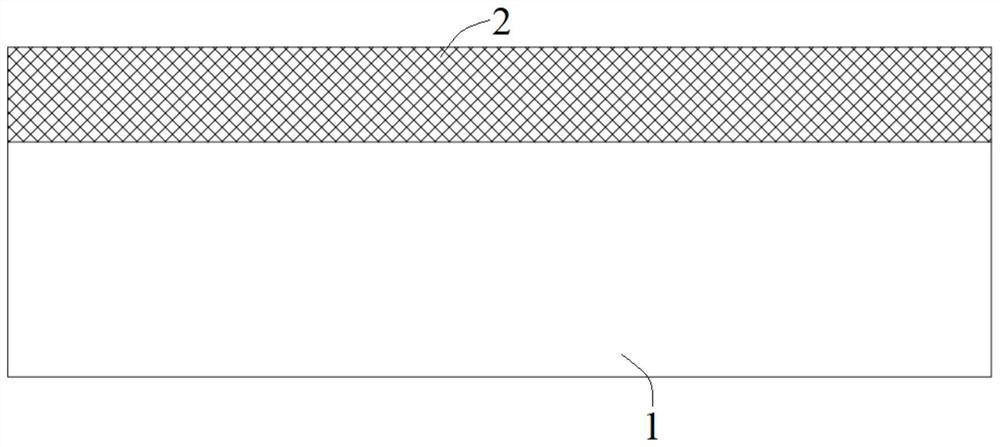

[0046] In the production process of inserting steel blade, the inventor finds that common slotting welding method has very big defective, traces it to its cause: traditional inserting steel blade (referring to figure 1 ) has a certain shape error (flatness) between the surface of the blade base and the bottom surface of the inlaid steel, resulting in no welding consumables on the joint surface, which in turn causes virtual, missing, or empty welding between the blade base and the inlaid steel. This causes very big economic loss and time loss to the steel insert blade manufacturer. In order to solve this problem, the inventor made an innovative improvement and provided a steel insert blade, which includes a blade base 1 and an alloy blade 4, and a welding surface 2 is arranged between the blade base 1 and the alloy blade 4 , the welding surface 2 is processed with a lattice structure. The lattice structure increases the surface roughness of the welding surface, indirectly incr...

Embodiment 2

[0048] to combine figure 2 , The steel-inserted blade of this embodiment has a lattice structure formed by two groups of lines intersecting each other, and a single group of lines is composed of a plurality of parallel straight lines. This form of lattice structure is completed by scraping by a fitter, or is processed by knurling, which can also increase the surface roughness of the welding surface, increase the solder stored on the joint surface of the blade base 1 and the alloy blade 4, and increase the welding material on the welding surface. The attachment area increases the bonding strength between the steel (tungsten steel / alloy) and the substrate.

Embodiment 3

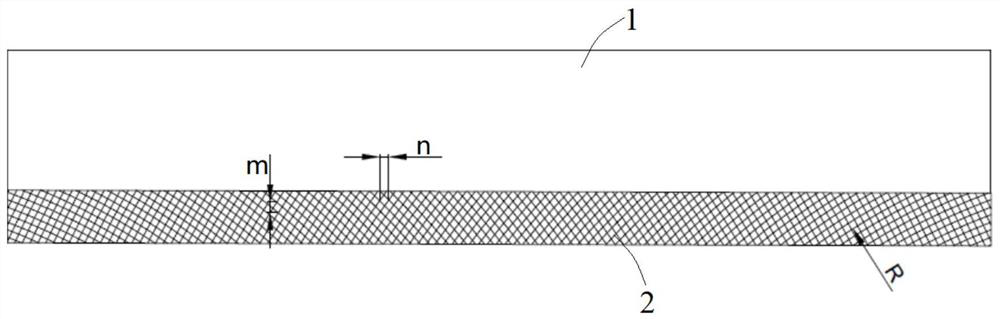

[0050] to combine image 3 , the steel-inserted blade of this embodiment, its lattice structure is formed by two groups of lines intersecting each other, and a single group of lines is composed of a plurality of equally spaced circular arc lines.

[0051] It is worth noting that the lattice structure in the form described in Example 2 is completed by scraping by a fitter, or is formed by knurling. Although it has the basic effect of welding the steel insert blade that this patent wants to achieve, it is scraped by a fitter, or The use of knurling processing has the disadvantages of high labor intensity, slow processing speed, and the need to be processed by a CNC machining center with a complex structure. The large investment in equipment leads to high processing costs, which is not conducive to popularization.

[0052] In view of the above problems, this embodiment provides an arc-shaped lattice structure, which forms a closed lattice pattern by intersecting the return patter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com