Preparation method of low-VOC vehicle interior material

A technology of interior materials and pellets, which is applied in the field of preparation of low-VOC car interior materials, can solve the problems that cannot be completely removed, small molecular substances will be desorbed or regenerated, and achieve the effect of low VOC release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

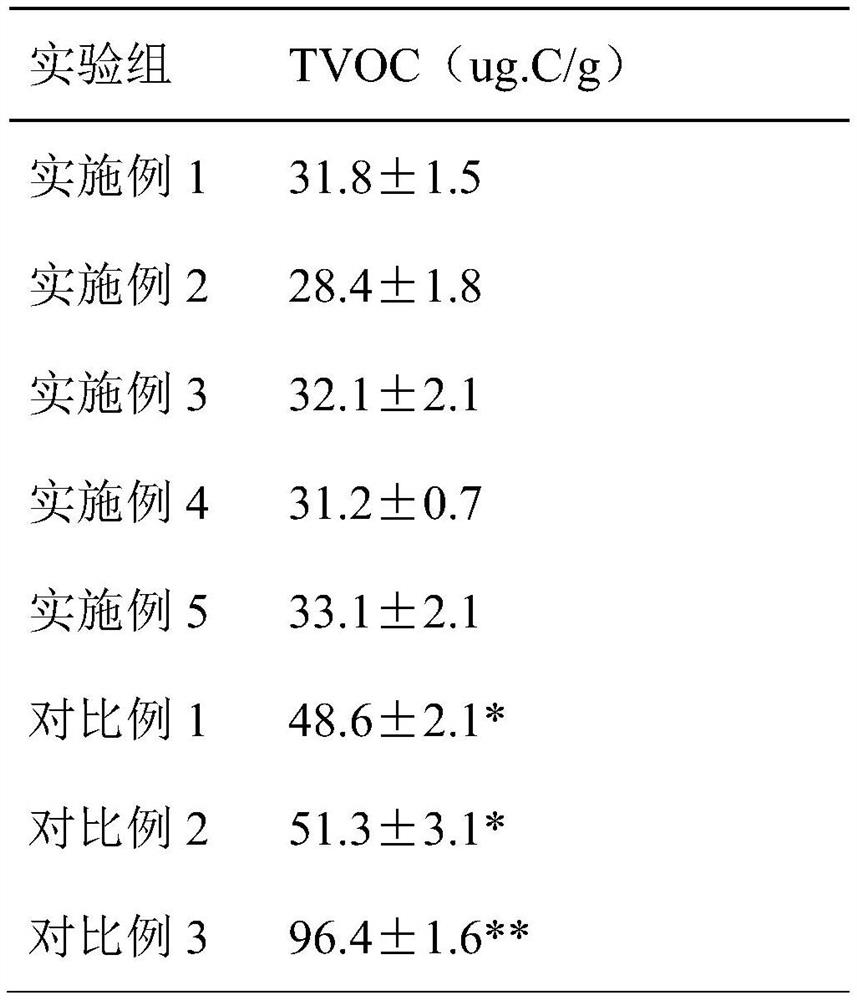

Examples

Embodiment 1

[0021] A preparation method of a low-VOC vehicle interior material is carried out according to the following steps:

[0022] (1) According to the parts by weight, take 90 parts of polypropylene resin, 20 parts of VOC inhibitor, 10,105 parts of antioxidant, 20 parts of montmorillonite, 5 parts of diethyl malonate, and 3 parts of EPDM rubber. Put into a high-speed mixer, and stir for 8 minutes at a stirring rate of 500 rpm to obtain a mixture; the VOC inhibitor is a mixture of hydroxyaluminum p-tert-butylbenzoate and zinc-aluminum hydrotalcite in a mass ratio of 1:1;

[0023] (2) dropping the mixed material into the twin-screw extruder and melting, extruding and pelletizing to obtain pellets; the screw speed of the twin-screw extruder is 400rpm, and the vacuum degree is 0.1MPa, and the processing of the twin-screw extruder The temperature is 200℃;

[0024] (3) The pellets in step (2) are sent into an oven, the oven temperature is adjusted to 80° C., and the temperature is kept ...

Embodiment 2

[0026] A preparation method of a low-VOC vehicle interior material is carried out according to the following steps:

[0027] (1) According to parts by weight, take 80 parts of polypropylene resin, 12 parts of VOC inhibitor, 10764 parts of antioxidant, 12 parts of sepiolite, 4 parts of 4-acetoacetamido phenylphosphonate, acrylate grafted Put 2 parts of styrene-based elastomer into a high-speed mixer, and stir for 8 minutes under the condition of a stirring speed of 320 rpm to obtain a mixture; the VOC inhibitor is hydroxyaluminum p-tert-butylbenzoate and zinc-aluminum hydrotalcite according to the mass ratio 1:1 mixed mixture;

[0028] (2) dropping the mixed material into the twin-screw extruder and melting, extruding and pelletizing to obtain pellets; the screw speed of the twin-screw extruder is 320rpm, and the vacuum degree is 0.06MPa, and the processing of the twin-screw extruder The temperature is 160℃;

[0029] (3) The pellets in step (2) are sent into an oven, the oven...

Embodiment 3

[0031] A preparation method of a low-VOC vehicle interior material is carried out according to the following steps:

[0032] (1) According to the parts by weight, take 100 parts of polypropylene resin, 30 parts of VOC inhibitor, 8 parts of antioxidant 264, 30 parts of medical stone, 6 parts of ethoxy modified trisiloxane, linear low density polymer Put 5 parts of ethylene into a high-speed mixer, and stir for 6 minutes at a stirring rate of 650 rpm to obtain a mixture; the VOC inhibitor is hydroxyaluminum p-tert-butylbenzoate and zinc-aluminum hydrotalcite mixed in a mass ratio of 1:1 mixture;

[0033] (2) the mixture is dropped into the twin-screw extruder and melted, extruded and pelletized to obtain pellets; the screw speed of the twin-screw extruder is 350rpm, and the degree of vacuum is 0.2MPa, and the processing of the twin-screw extruder The temperature is 220℃;

[0034] (3) The pellets in step (2) are sent into an oven, the oven temperature is adjusted to 90° C., and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com