Polyurea coating, coating and preparation method thereof

A technology of polyurea and paint, applied in the field of paint, can solve the problems of insufficient hydrophobicity, poor color retention, slow reaction and weather resistance, etc., and achieve the effect of increasing gloss and color retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

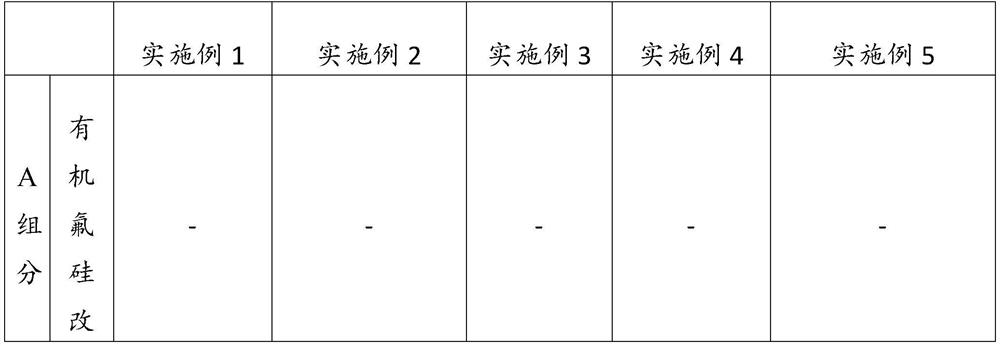

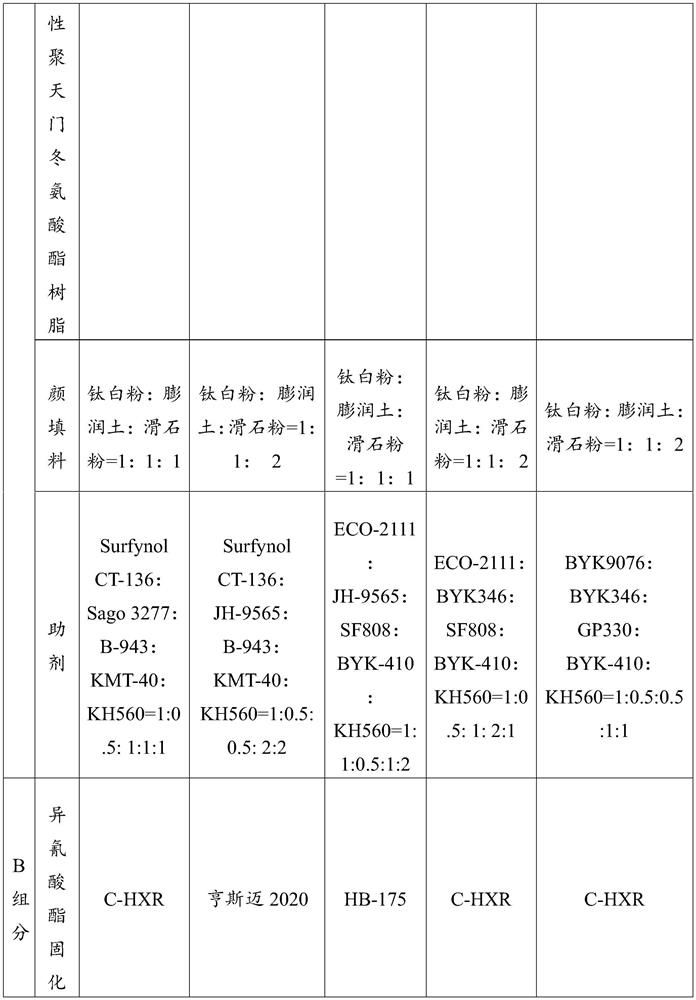

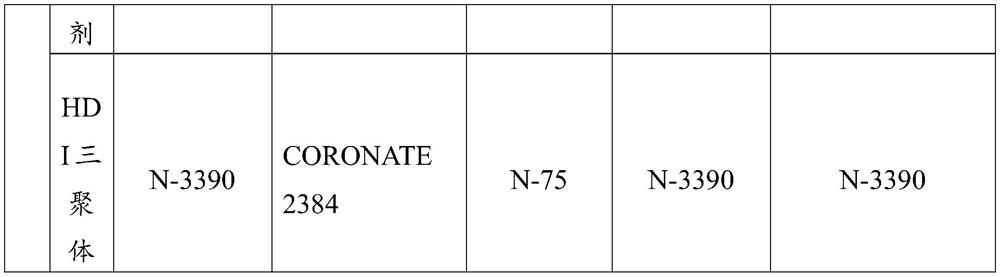

[0034] After carrying out component weighing according to table 1 and table 2, the preparation method of polyurea coating described in embodiment, comprises the steps:

[0035] (1) Mix the A component uniformly, and add it to the uniformly mixed B component to obtain the polyurea coating;

[0036] (2) After uniformly mixing the polyurea coating obtained in step (1), spray, manually brush or roll coat it on the metal within 90 minutes to obtain the polyurea coating.

[0037] Wherein, in component A, the preparation method of the organofluorosilicon-modified polyaspartate resin comprises the following steps:

[0038] (1) After mixing polyaspartic acid ester resin, γ-aminopropyltrialkoxysilane and trifluoropropylmethylcyclotrisiloxane, pass inert gas, after 5min, heat up to 55°C, Diethyl maleate was added dropwise with stirring to obtain a mixture;

[0039] (2) Heat the mixture for 10 hours, the heat preservation temperature is 55° C., and obtain the organofluorosilicon-modifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com