Leather texture primer as well as preparation method and application thereof

A skin texture and primer technology, applied in primers, coatings, polyurea/polyurethane coatings, etc., can solve problems such as affecting the appearance and service life of products, poor imitation skin texture, and shell corrosion, and achieve good application. Foreground, good vibrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1 of the present invention is: a leather texture paint, comprising the following raw materials: leather texture primer and topcoat.

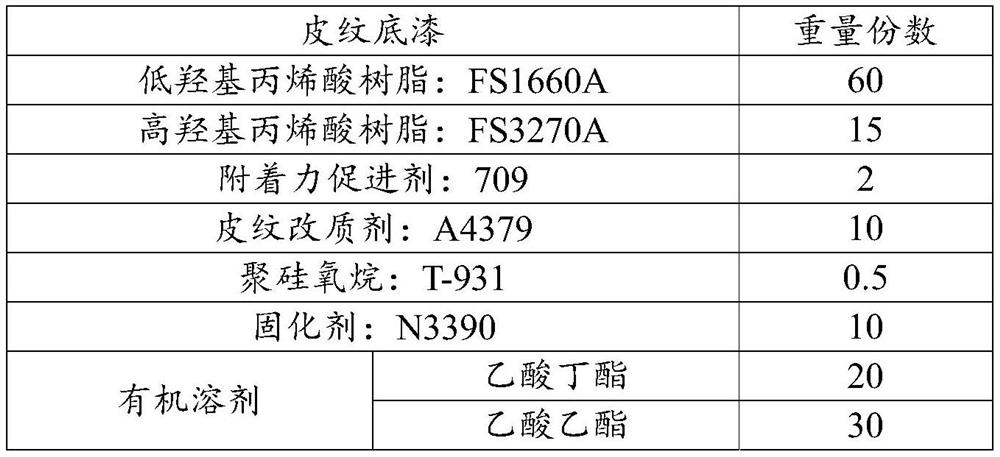

[0065] The parts by weight of each composition in table 1 embodiment 1 skin pattern primer

[0066]

[0067] The preparation method of above-mentioned skin grain primer: comprise the following steps:

[0068] S1. Preheat the low-hydroxyl acrylic resin and the high-hydroxyl acrylic resin at 55° C. for 60 minutes, mix and dissolve them with (10 parts of ethyl acetate and 10 parts of butyl acetate) part of the organic solvent to form the first mixed solution;

[0069] S2. Add an adhesion promoter, a skin texture modifier, polysiloxane and a curing agent to the first mixed solution in the step S1 and mix under stirring to form a second mixed solution; wherein, the mixing temperature The temperature is 50°C, the stirring time is 30min, and the stirring speed is 600 rpm;

[0070] S3. Add the remaining organic solvent to the seco...

Embodiment 2

[0075] Embodiment 2 of the present invention is: a kind of skin texture paint, and the difference with embodiment 1 is: skin texture primer.

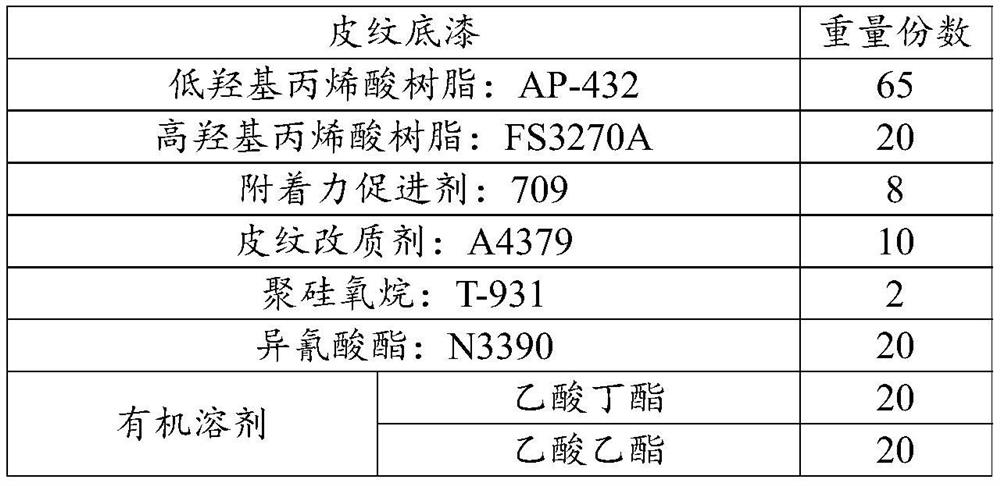

[0076] The ingredients and parts by weight of the skin texture primer of this embodiment are shown in Table 2.

[0077] The parts by weight of each component in table 2 embodiment 2 skin texture primer

[0078]

Embodiment 3

[0079] Embodiment 3: a kind of skin texture paint, the difference with embodiment 1 is: skin texture primer.

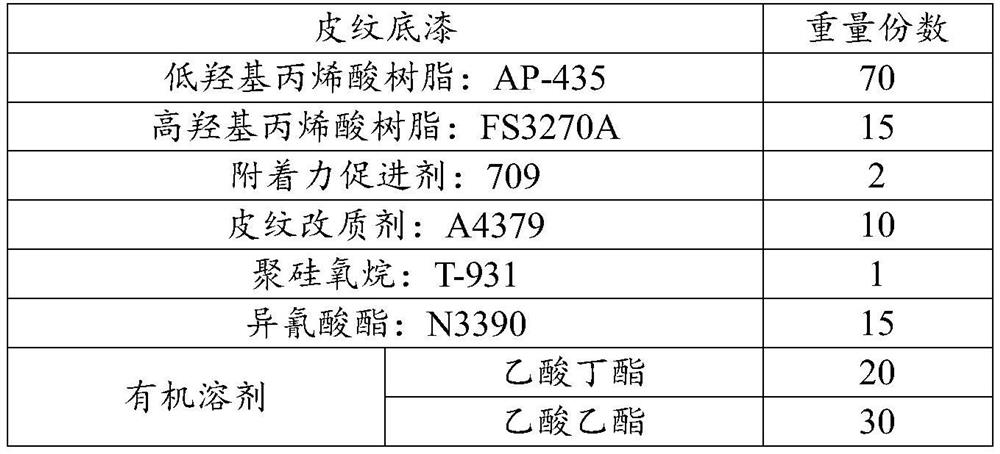

[0080] The ingredients and parts by weight of the texture primer of this embodiment are shown in Table 3.

[0081] The parts by weight of each composition in table 3 embodiment 3 skin pattern primers

[0082]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com