I-shaped microstructure optical fiber electro-optical modulator based on two-dimensional material coating

A technology of microstructured optical fiber and electro-optical modulator, applied in the directions of microstructured optical fiber, cladding optical fiber, optical waveguide light guide, etc., can solve the problems of inability to meet, destroy the optical fiber structure, loss, etc., achieve low insertion loss, reduce the difficulty of realization, Effect of low modulation voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

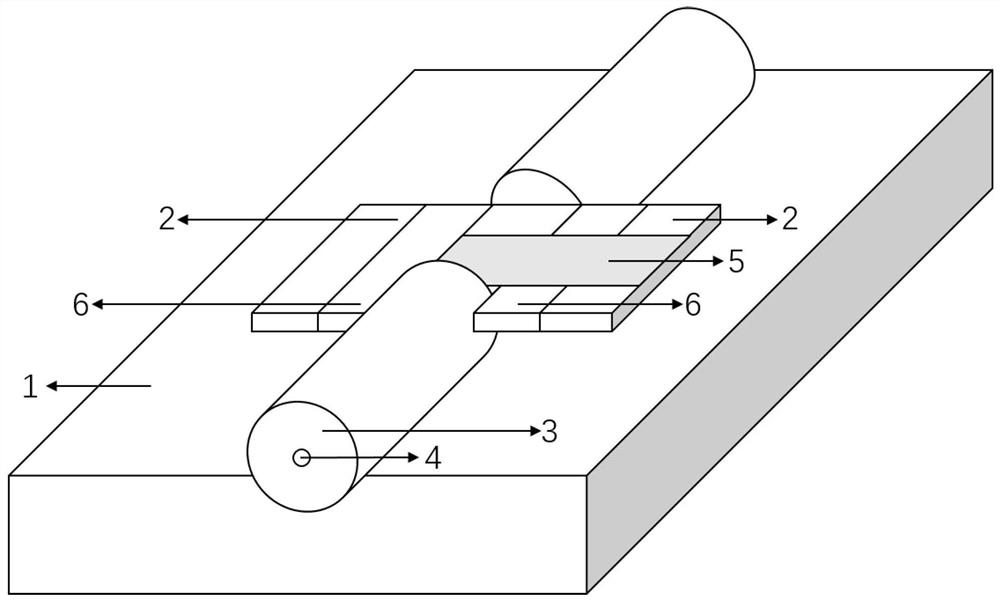

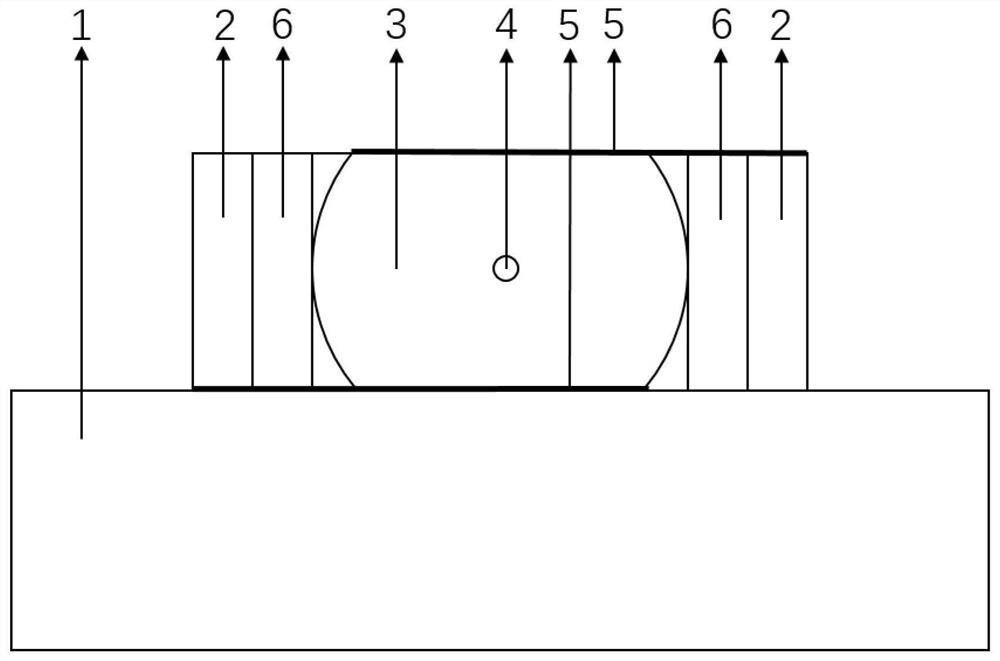

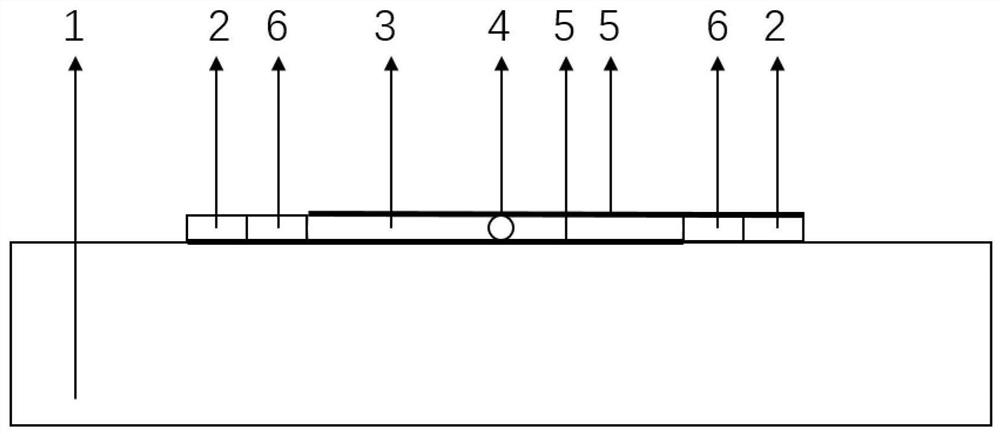

[0017] I-shaped microstructure fiber electro-optic modulator based on two-dimensional material coating such as figure 1 shown. Silicon substrate 1, electrode 2, common single-mode optical fiber cladding 3, fiber core 4, two-dimensional material film 5 and silicon support 6.

[0018] The specific combination method is as follows: the ordinary single-mode optical fiber cladding 3 is cut and ground to form an I-shaped structure, and the upper and lower layers are respectively processed to the same distance from the fiber core 4; the two-dimensional material film 5 is respectively written on the upper surface of the silicon substrate 1 and On the upper side of the I-shaped optical fiber, the I-shaped optical fiber is reversely stacked on the substrate; the electrode 2 is plated on both sides of the silicon support 6 and connected to the two-dimensional material film to provide the voltage required for modulation and change the optical signal intensity or phase.

[0019] The silic...

Embodiment 2

[0022] I-shaped microstructure fiber electro-optic modulator based on two-dimensional material coating such as figure 1 shown. Silicon substrate 1, electrode 2, common single-mode optical fiber cladding 3, fiber core 4, two-dimensional material film 5 and silicon support 6.

[0023] The specific combination method is: the ordinary single-mode optical fiber cladding 3 is cut and ground to form an I-shaped structure, and the upper and lower layers are respectively processed to the same distance from the fiber core 4 to ensure that the main part of the light field is transmitted in the fiber core; the two-dimensional material The thin film 5 is respectively written on the upper surface of the silicon substrate 1 and the upper side of the I-shaped optical fiber, and then the I-shaped optical fiber is reversely stacked on the substrate; the electrode 2 is plated on both sides of the silicon support 6 and connected with the two-dimensional material film to provide modulation. The r...

Embodiment 3

[0027] I-shaped microstructure fiber electro-optic modulator based on two-dimensional material coating such as figure 1 shown. Silicon substrate 1, electrode 2, common single-mode optical fiber cladding 3, fiber core 4, two-dimensional material film 5 and silicon support 6.

[0028]The specific combination method is as follows: the ordinary single-mode optical fiber cladding 3 is cut and ground to form an I-shaped structure, and the upper and lower layers are respectively processed to the same distance from the fiber core 4; the two-dimensional material film 5 is respectively written on the upper surface of the silicon substrate 1 and On the upper side of the I-shaped optical fiber, the I-shaped optical fiber is reversely stacked on the substrate; the electrode 2 is plated on both sides of the silicon support 6 and connected to the two-dimensional material film to provide the voltage required for modulation and change the optical signal intensity or phase.

[0029] The silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com