A co-crystal of coenzyme QH and nicotinamide and its preparation method and application

A technology of nicotinamide and coenzyme, which is applied in ether preparation, organic chemical methods, organic chemistry, etc., can solve problems such as oxidation and co-crystallization preparation methods, and achieve improved chemical stability, excellent chemical stability, and good reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Add 10 grams of oxidized coenzyme Q10 and 6 grams of L-ascorbic acid to 100 grams of 95% ethanol, stir at 78°C for reduction reaction, cool to 0°C after 20 hours, keep stirring at this temperature for 1 hour, and filter under reduced pressure . The filter cake was rinsed three times with 95% ethanol, and dried under reduced pressure to obtain a white eutectic. All operations were performed under nitrogen protection except drying under reduced pressure. The weight ratio of coenzyme QH / oxidized coenzyme Q10 in the obtained sample was 99.2 / 0.8.

[0075] This powder is detected by differential scanning calorimetry (DSC), the result Figure 13 shown. Depend on Figure 13 It can be seen that QH has a characteristic endothermic peak at about 49 °C.

Embodiment 2

[0077] Add 0.4 g of nicotinamide and 1 g of the coenzyme QH obtained in Example 1 to 10 ml of isopropanol / isopropyl acetate = 1 / 1 solvent, stir and dissolve at 40°C, and recrystallize to obtain a white precipitate , filtered the precipitate through a Buchner funnel, and dried the solid in a vacuum oven at room temperature for 12 hours to obtain a co-crystal of coenzyme QH and nicotinamide.

[0078] The contents of coenzyme QH and nicotinamide in the co-crystal of coenzyme QH and nicotinamide were measured respectively by high performance liquid chromatography, and it was found that the content of coenzyme QH was about 86.1%, and the content of nicotinamide was about 12.6%. In this co-crystal, the stoichiometric ratio of coenzyme QH to nicotinamide is about 1:1.

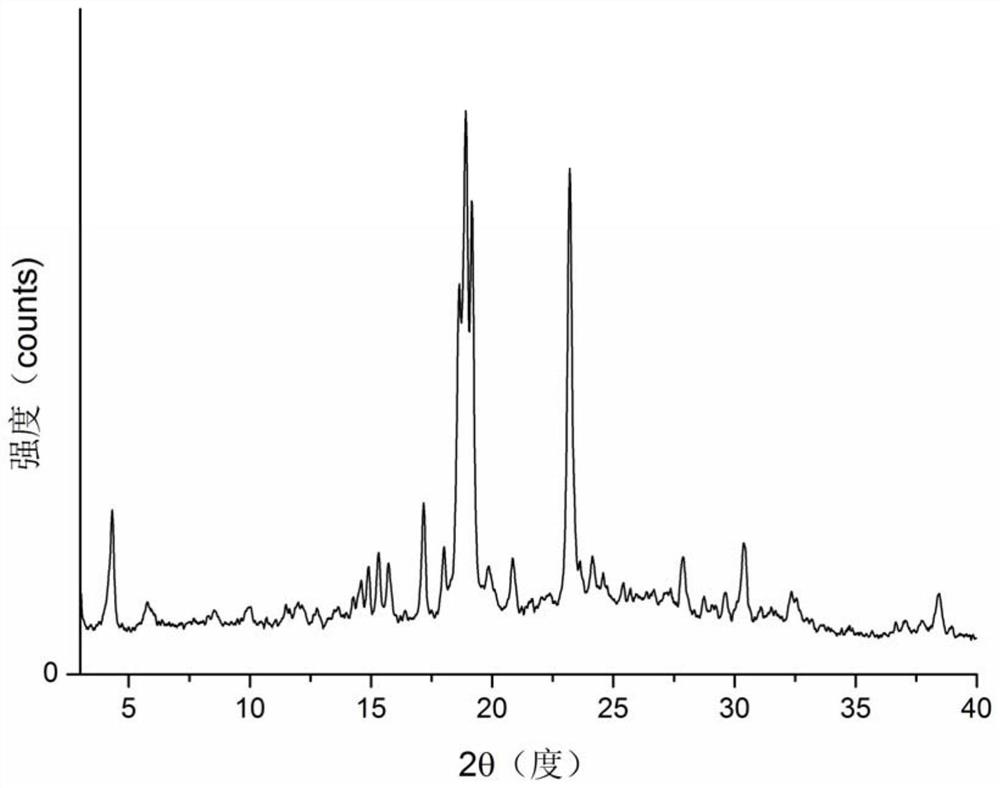

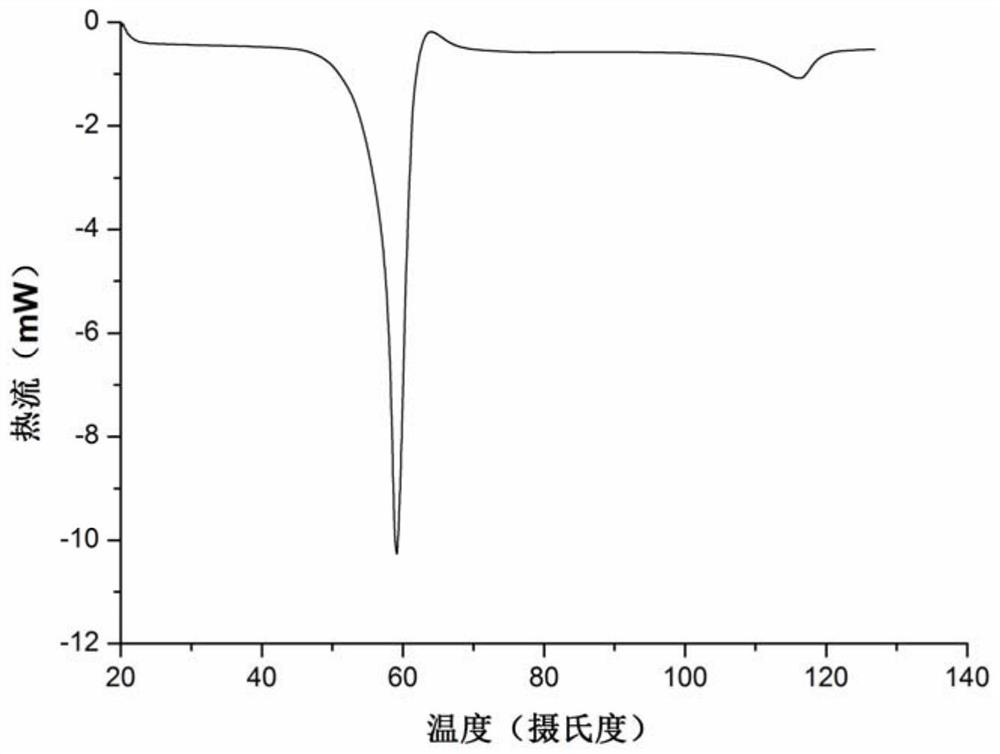

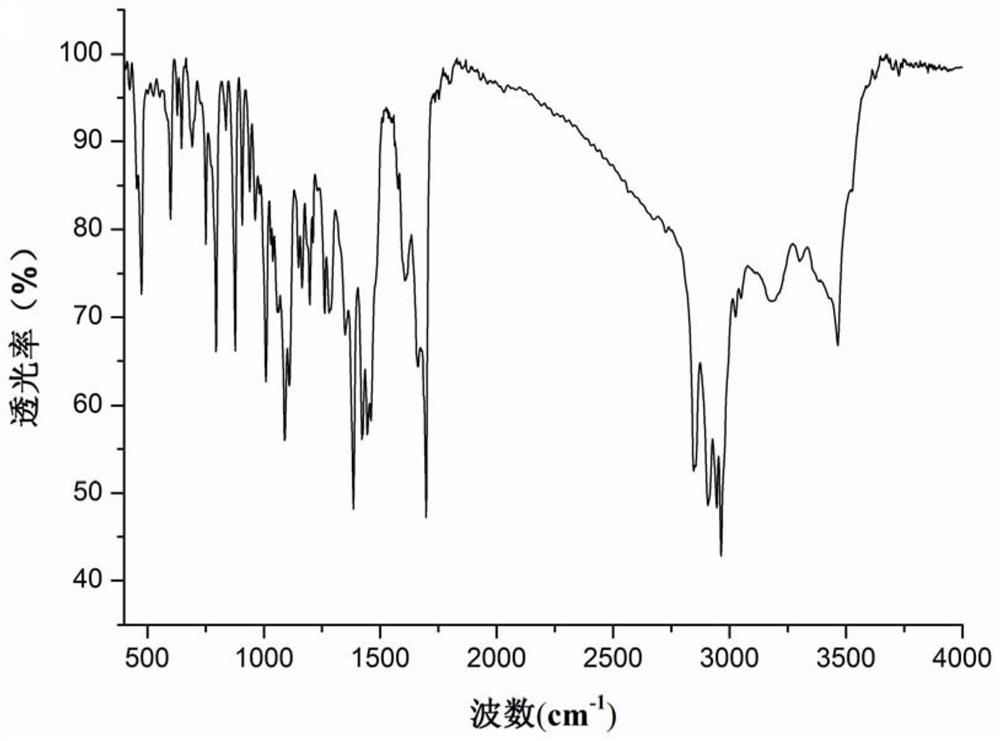

[0079] This co-crystal was characterized by solid state methods such as X-ray powder diffraction (XRPD), differential scanning calorimetry (DSC) and infrared (IR) spectroscopy. The results are as follows Figure 1-F...

Embodiment 3

[0084] Add 0.122 g of nicotinamide and 0.87 g of the coenzyme QH obtained in Example 1 into 2 ml of ethanol, stir and dissolve at 60°C, recrystallize to obtain a white solid, and dry the solid in a vacuum oven at room temperature for 12 hours. A co-crystal of coenzyme QH and nicotinamide was obtained.

[0085] The contents of coenzyme QH and nicotinamide in the co-crystal of coenzyme QH and nicotinamide were measured respectively by high performance liquid chromatography, and it was found that the content of coenzyme QH was about 84.0%, and the content of nicotinamide was about 11.8%. In this co-crystal, the stoichiometric ratio of coenzyme QH to nicotinamide is about 1:1.

[0086] This is characterized by solid state methods such as X-ray powder diffraction (XRPD), differential scanning calorimetry (DSC) and infrared (IR) spectroscopy. The results are basically consistent with the co-crystal detection results of coenzyme QH and nicotinamide in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com