Liquid metal radiation shielding coating material and preparation method thereof

A coating material and radiation shielding technology, applied in the field of materials, can solve problems such as quality reduction, and achieve the effects of convenient operation, easy coating and good viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

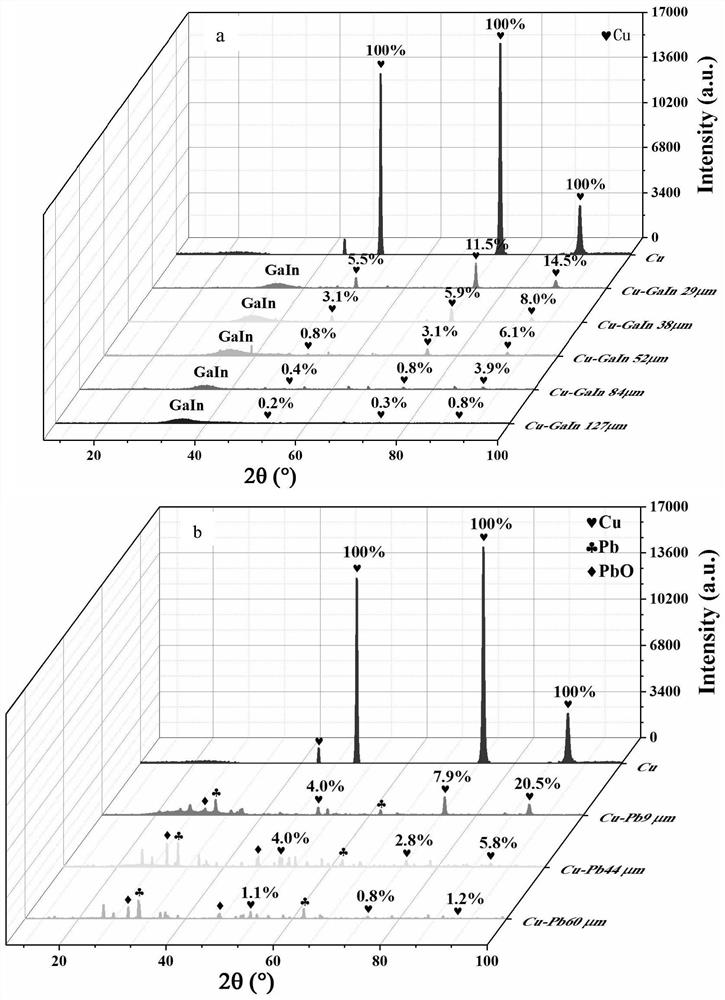

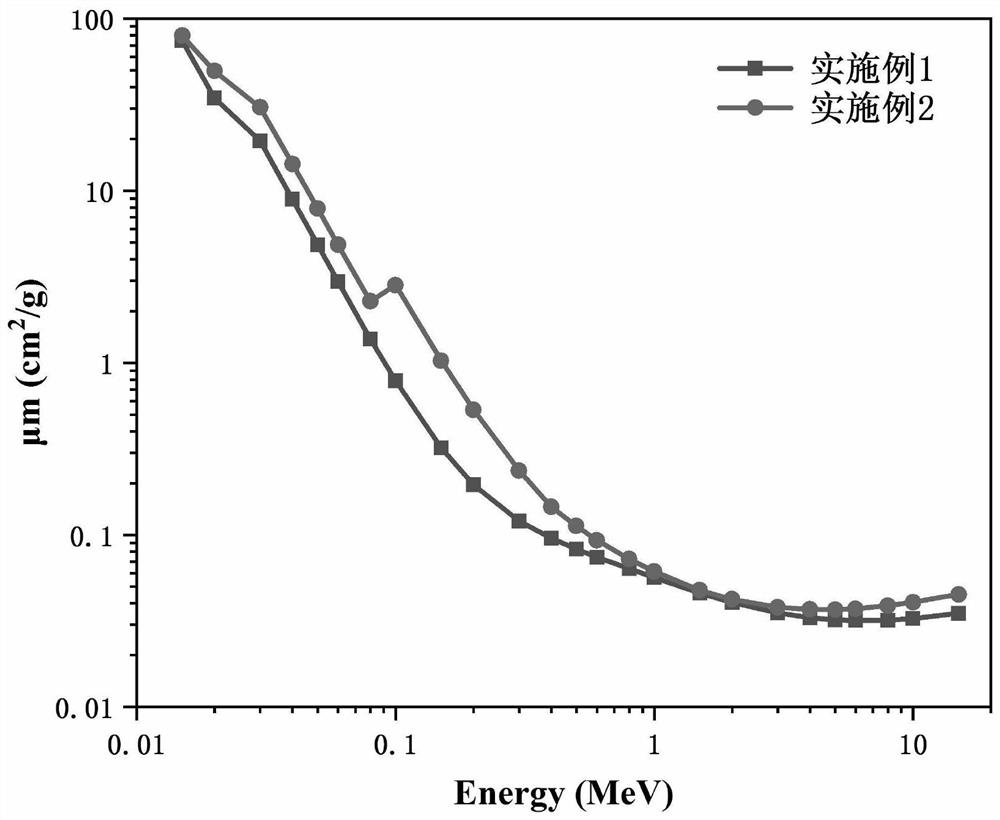

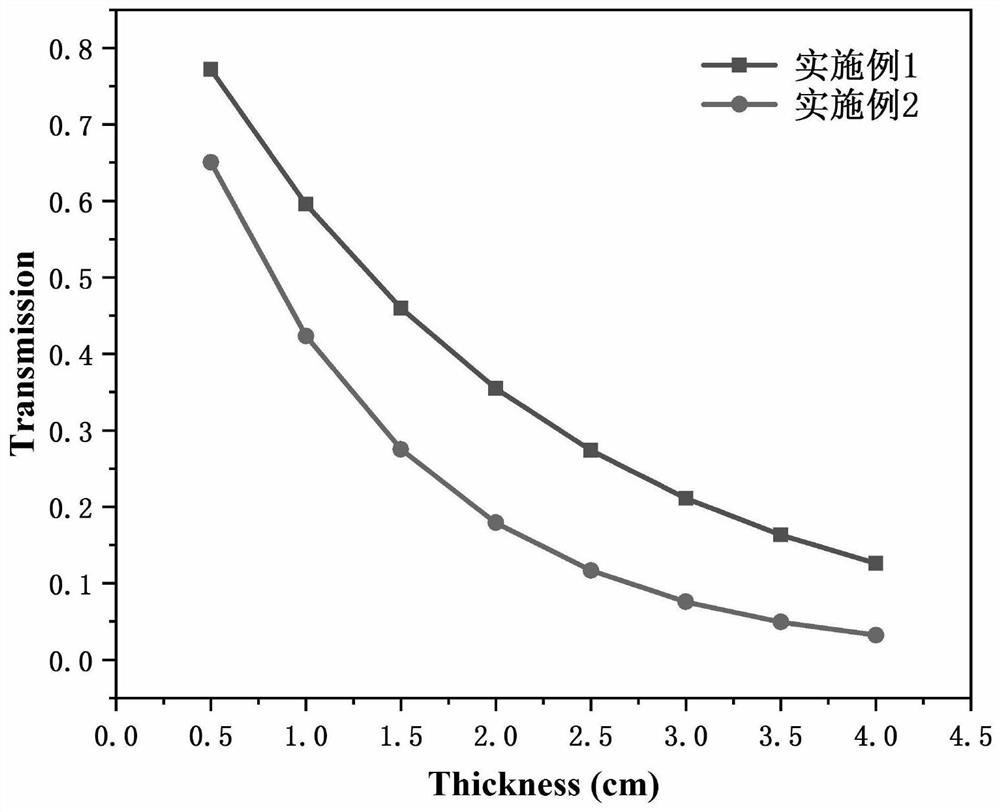

[0020] Embodiment 1: The liquid metal radiation shielding coating material of this embodiment is Ga 83 In 17 ;

[0021] Liquid Metal Radiation Shielding Coating Material Ga 83 In 17 The preparation method, concrete steps are as follows:

[0022] (1) Clean the metal elemental raw materials Ga and In with dilute hydrochloric acid with a mass concentration of 3 to 5% to remove the oxide layer, and then use deionized water to clean them, then put them into acetone for ultrasonic treatment to remove surface grease, then wash them with deionized water, and dry them. That is, pure metal substances Ga and In are obtained;

[0023] (2) According to the stoichiometric ratio of Ga and In 83:17, mix the pure metal substances Ga and In in step (1) evenly, place in a vacuum induction furnace, and raise the temperature to 120 °C at a constant rate of 5-10 °C / min. ℃ and smelting at constant temperature for 2 to 4 hours, then cool down with the furnace to obtain alloy samples, that is, th...

Embodiment 2

[0025] Embodiment 2: The liquid metal radiation shielding coating material of this embodiment is Ga 20 In 20 sn 20 Bi 20 Zn 20 ;

[0026] Liquid Metal Radiation Shielding Coating Material Ga 20 In 20 sn 20 Bi 20 Zn 20 The preparation method, concrete steps are as follows:

[0027] (1) The metal elemental raw materials Ga, In, Sn, Bi and Zn are washed with dilute hydrochloric acid with a mass concentration of 3 to 5% to remove the oxide layer, cleaned with deionized water, put into acetone and ultrasonically treated to remove surface grease, and then Wash with deionized water and dry to obtain pure metal substances Ga, In, Sn, Bi and Zn;

[0028] (2) According to the stoichiometric ratio of Ga, In, Sn, Bi and Zn 20:20:20:20:20:20, the pure metal substances Ga, In, Sn, Bi and Zn in step (1) are mixed evenly, and placed In a vacuum induction furnace, heat up to 430°C at a constant rate of 5-10°C / min and smelt at a constant temperature for 2-4 hours, then cool down in t...

Embodiment 3

[0030] Embodiment 3: The liquid metal radiation shielding coating material of this embodiment is Ga 50 In 30 sn 20 ;

[0031] Liquid Metal Radiation Shielding Coating Material Ga 50 In 30 sn 20 The preparation method, concrete steps are as follows:

[0032] (1) Clean the metal elemental raw materials Ga, In and Sn with dilute hydrochloric acid with a mass concentration of 3 to 5% to remove the oxide layer, clean with deionized water, put them in acetone for ultrasonic treatment to remove surface grease, and then clean with deionized water , and dry to obtain pure metal substances Ga, In and Sn;

[0033] (2) According to the stoichiometric ratio of Ga, In and Sn 50:30:20, the pure metal substances Ga, In and Sn in step (1) are mixed uniformly, placed in a vacuum induction furnace, and heated at a temperature of 5-10°C / min. Heating rate Raise the temperature to 260°C at a constant speed and smelt at a constant temperature for 2 to 4 hours to cool down in the furnace to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com