Preparation of graphene/silicon carbide three-dimensional composite aerogel and loaded molybdenum disulfide electrocatalyst thereof

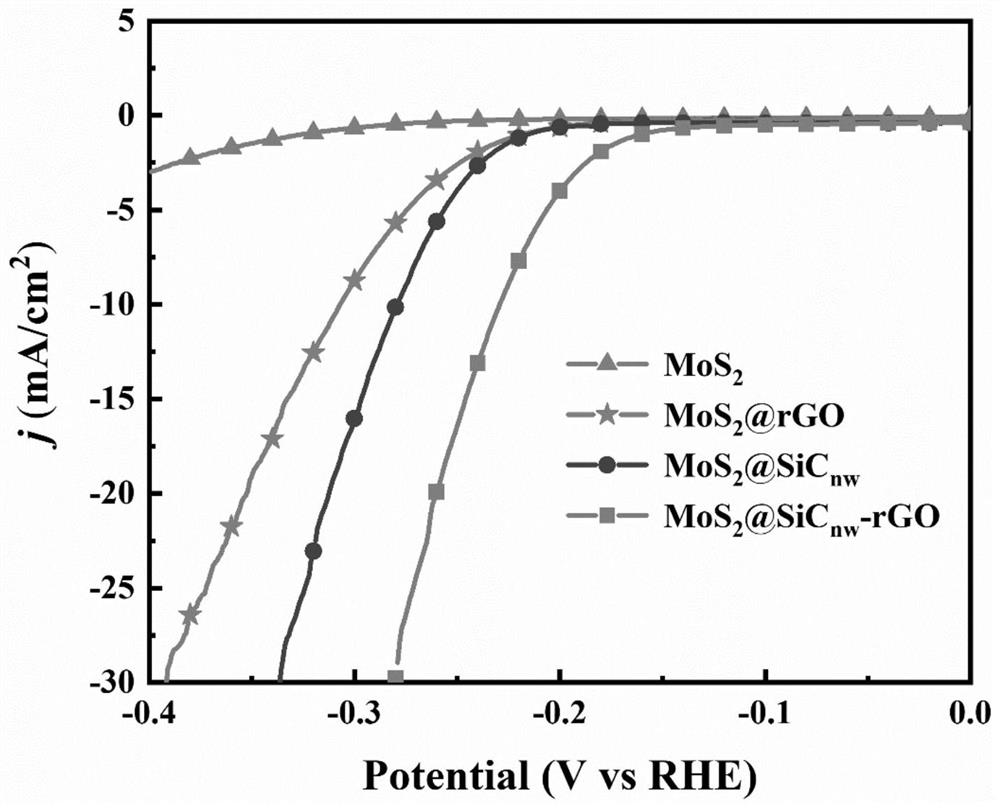

A composite aerogel and three-dimensional composite technology, which is applied in the preparation and application fields of electrocatalytic hydrogen production, to achieve the effects of improving electrical conductivity and stability, enhancing electrocatalytic hydrogen production performance, and reducing activation barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

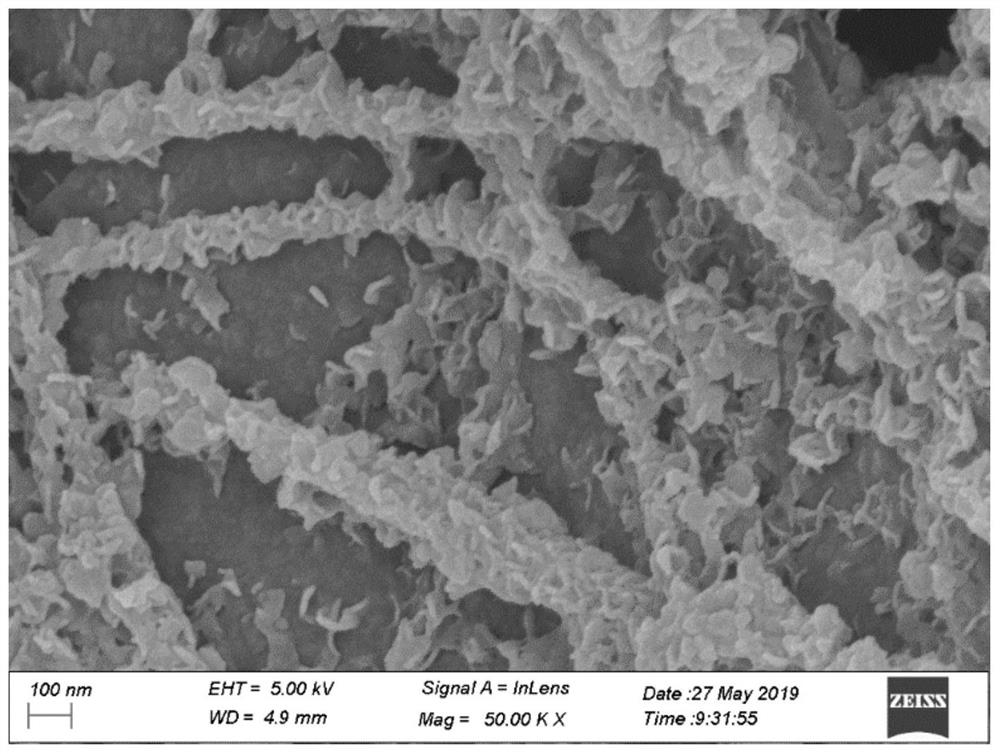

[0030] A kind of preparation of graphene / silicon carbide three-dimensional composite airgel and the method for carrying molybdenum disulfide electrocatalyst thereof, comprise the following steps, mix 0.5g graphene and 0.86g silica sol in the solvent of water and ethanol, pump Filter into blocks and dry at 120°C; mix 20g of carbon felt and 3.7g of silica sol in a solvent of water and ethanol, and dry at 120°C; spread the carbon felt on the bottom of a graphite crucible, and then filter it with suction to obtain Place the graphene block on the top of the carbon felt and cover the crucible lid; under the protection of 0.5MPa argon, heat it to 1300°C at a heating rate of 5°C / min, and keep it at 1300°C for 2h to obtain graphene / carbonized Silicon three-dimensional composite airgel. Add 0.6g of sodium molybdate and 0.75g of thioacetamide into 30mL of deionized water, stir for 30 minutes, then add 0.01g of graphene / silicon carbide three-dimensional composite airgel, soak for 12h; tra...

Embodiment 2

[0035] A kind of preparation of graphene / silicon carbide three-dimensional composite airgel and the method for carrying molybdenum disulfide electrocatalyst thereof, comprise the following steps, 0.9g graphene and 1.2g silica sol are mixed uniformly in the solvent of water and ethanol, pumping Filter into blocks and dry at 120°C; mix 22g of carbon felt and 4.5g of silica sol in a solvent of water and ethanol, and dry at 120°C; spread the carbon felt on the bottom of a graphite crucible, and then filter with suction to obtain Place the graphene block on the top of the carbon felt and cover the crucible lid; under the protection of 0.8MPa argon, heat it to 1450°C at a heating rate of 8°C / min, and keep it at 1450°C for 2h to obtain graphene / carbonized Silicon three-dimensional composite airgel. Add 0.6g of sodium molybdate and 0.75g of thioacetamide into 30mL of deionized water, stir for 30 minutes, then add 0.01g of graphene / silicon carbide three-dimensional composite airgel, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com