Method for detecting corrosion activity of inclusions in low alloy steel

A detection method and technology for low-alloy steel, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to analyze the composition of inclusions, deteriorate the corrosion resistance of steel, etc., and achieve the effect of reliable data and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A method for detecting the corrosion activity of inclusions in low alloy steels. The steps of detection method described in the present embodiment are:

[0070] Step 1. Cut a sample of 10mm×10mm×10mm on the EH36 steel plate as the original sample to be tested;

[0071] Step 2: Polish the original sample to be tested with silicon carbide sandpaper, and then mechanically polish it until the surface roughness is less than 0.8 μm to obtain a polished sample to be tested; then use acetone, deionized water and alcohol to polish the sample to be tested in sequence. The test sample is cleaned and dried to obtain a prefabricated sample to be tested;

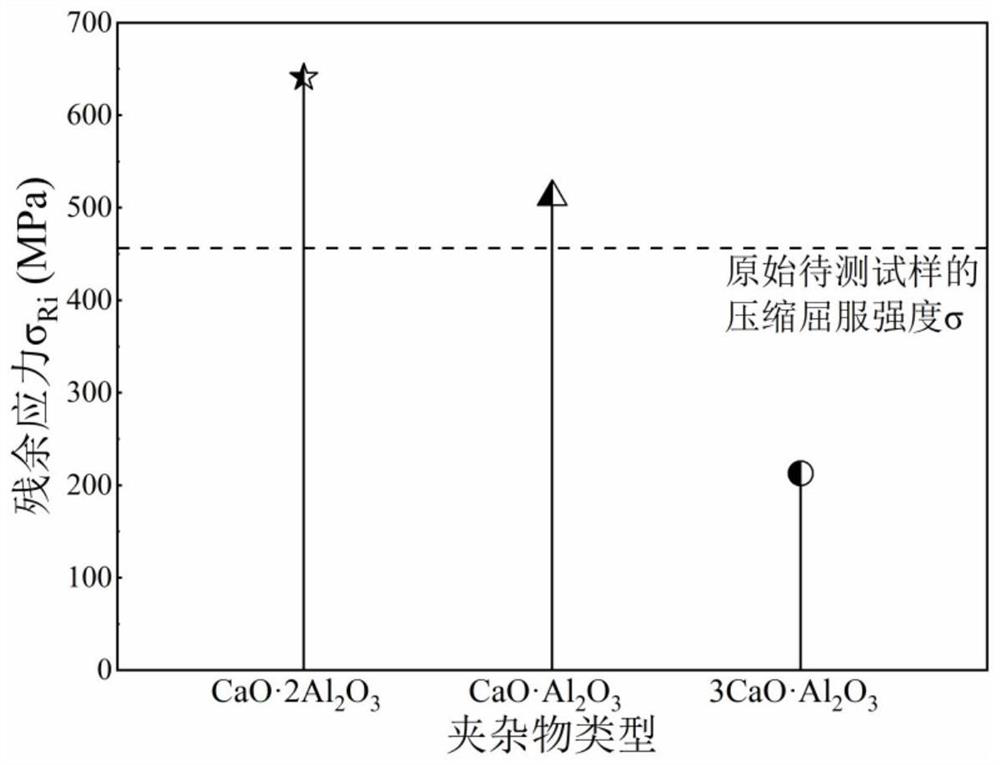

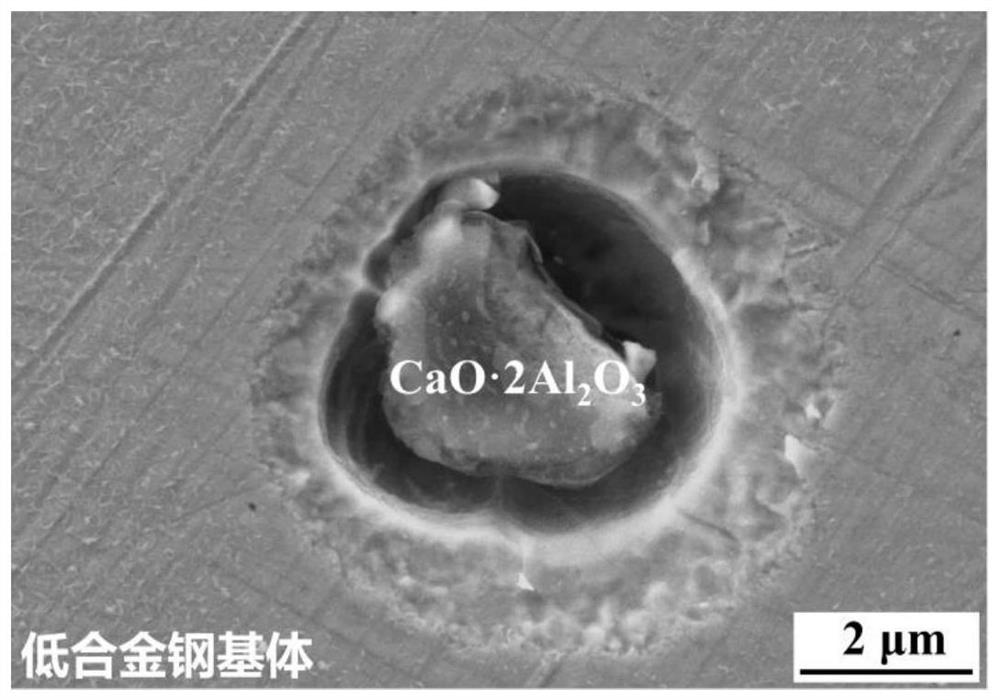

[0072] Step 3. Place the prefabricated sample to be tested in a fully automatic inclusion analyzer, and measure the number of inclusions in the prefabricated sample to be tested to be 475 and the density ρ to be 13mm -2 ; The inclusion density is the ratio of the number of inclusions in the statistical area to the area of the s...

Embodiment 2

[0097] A method for detecting the corrosion activity of inclusions in low alloy steels. The steps of detection method described in the present embodiment are:

[0098] Step 1. Cut a sample of 10mm×10mm×10mm on the aluminum deoxidized X70 pipeline steel as the original sample to be tested;

[0099] Step 2: Polish the original sample to be tested with silicon carbide sandpaper, and then mechanically polish it until the surface roughness is less than 0.8 μm to obtain a polished sample to be tested; then use acetone, deionized water and alcohol to polish the sample to be tested in sequence. The test sample is cleaned and dried to obtain a prefabricated sample to be tested;

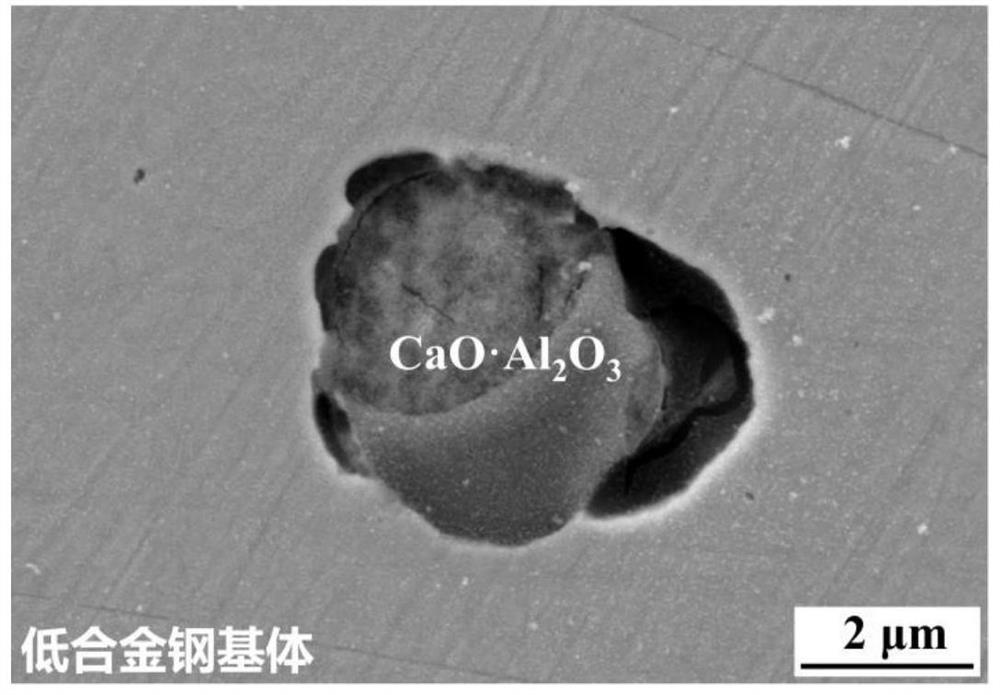

[0100] Step 3, place the prefabricated sample to be tested in the automatic inclusion analyzer, and measure the number of inclusions in the prefabricated sample to be tested to be 564, and the density ρ is 19mm -2 ; The inclusion density is the ratio of the number of inclusions in the statistical area to the...

Embodiment 3

[0122] A method for detecting the corrosion activity of inclusions in low alloy steels. The steps of detection method described in the present embodiment are:

[0123] Step 1. Cut a sample of 10mm×10mm×10mm on the Ti microalloyed X70 pipeline steel as the original sample to be tested;

[0124] Step 2: Polish the original sample to be tested with silicon carbide sandpaper, and then mechanically polish it until the surface roughness is less than 0.8 μm to obtain a polished sample to be tested; then use acetone, deionized water and alcohol to polish the sample to be tested in sequence. The test sample is cleaned and dried to obtain a prefabricated sample to be tested;

[0125] Step 3. Place the prefabricated sample to be tested in the automatic inclusion analyzer, and measure the number of inclusions in the prefabricated sample to be tested to be 3778, and the density ρ is 100mm -2 ; The inclusion density is the ratio of the number of inclusions in the statistical area to the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com