Laser radar system based on micromirror array

A laser radar and micromirror array technology, applied in the field of radar, can solve the problems of limited clear aperture, restricting the system's ability to collect echo energy, etc., to achieve the effect of reducing impact, low cost and high signal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In view of the above-mentioned unresolved problems, the present invention proposes a laser radar system, which aims to realize long-distance detection with a compact structure and a high signal-to-noise ratio.

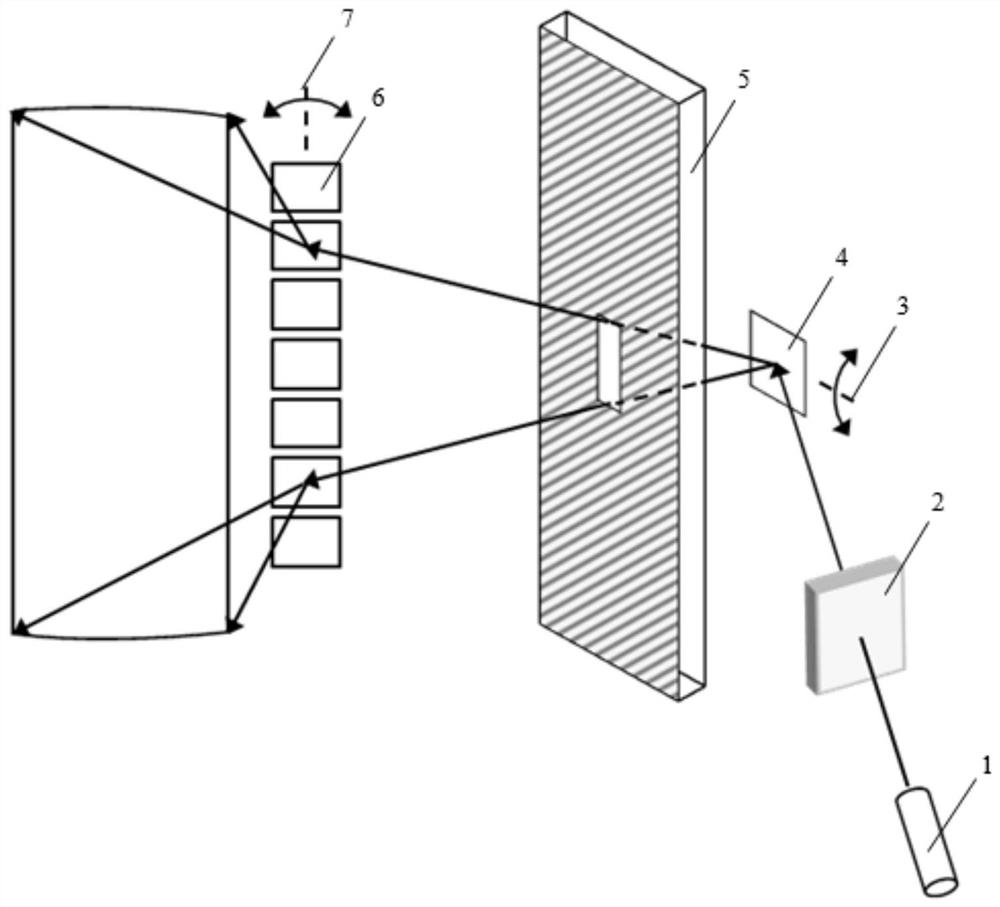

[0051] Such as figure 1 As shown, the laser light emitted by the laser 1 is collimated by the collimator lens 2 and then enters the vertical scanning micromirror 4 . The vertical scanning micromirror 4 is an electrostatically driven micromirror working in a quasi-static mode, which deflects and vibrates around the first rotating shaft 3, so that the incident laser beam scans within a certain angle in the vertical direction.

[0052] A reflective mirror 5 is arranged on the optical path of the laser beam, and the reflectivity of the reflective mirror 5 near the laser wavelength is close to 1. The reflector 5 only leaves a reflector light-transmitting area near the center, and the transmittance of the reflector light-transmitting area to the laser beam near the l...

Embodiment 2

[0064] In the foregoing embodiments, the vertical scanning micromirror 4 and the horizontal scanning micromirror array 6 are MEMS micromirror devices. It is made of SOI wafer and processed by semiconductor technology. The drive mode of the micromirror can be electrostatic drive, piezoelectric drive, electromagnetic drive, electrothermal drive, etc.

[0065] The vertical scanning micromirror 4 can adopt resonant scanning, quasi-static scanning or digital jump scanning.

[0066] The vertical scanning micromirror 4 can choose to use an electrostatically driven micromirror with planar comb teeth, or an electrostatically driven micromirror with a vertical comb tooth structure.

[0067] In a preferred example, the vertical scanning micromirror 4 is an electrostatically driven micromirror with a vertical comb structure.

[0068] The horizontal scanning micromirror array 6 can choose to use an electrostatically driven micromirror with a planar comb, or an electrostatically driven mi...

Embodiment 3

[0076] Such as image 3 As shown, in this embodiment, the width of the light-transmitting region of the reflector can be reduced, and a cylindrical mirror is formed on the light-transmitting region of the reflector, and the cylindrical mirror and the reflector form an integral body.

[0077] In a preferred example, an anti-reflection film is deposited on the outer surface of the cylindrical mirror, and a metal reflective layer is deposited on the area other than the cylindrical area.

[0078] The cylindrical lens structure can offset the diffraction effect that occurs when the laser passes through the light-transmitting area of the mirror, ensuring good collimation of the laser beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com