Absorption tower for flue gas desulfurization and method for equalizing flow of flue gas in absorption tower

An absorption tower and flue gas technology, which is applied in the field of flue gas equalization in the absorption tower for flue gas desulfurization and the absorption tower for flue gas desulfurization, can solve the problems of large flue gas resistance, large and unsatisfactory flue gas flow at the outlet side, etc. , to achieve the effect of saving system energy consumption, low flue gas resistance and good flow equalization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

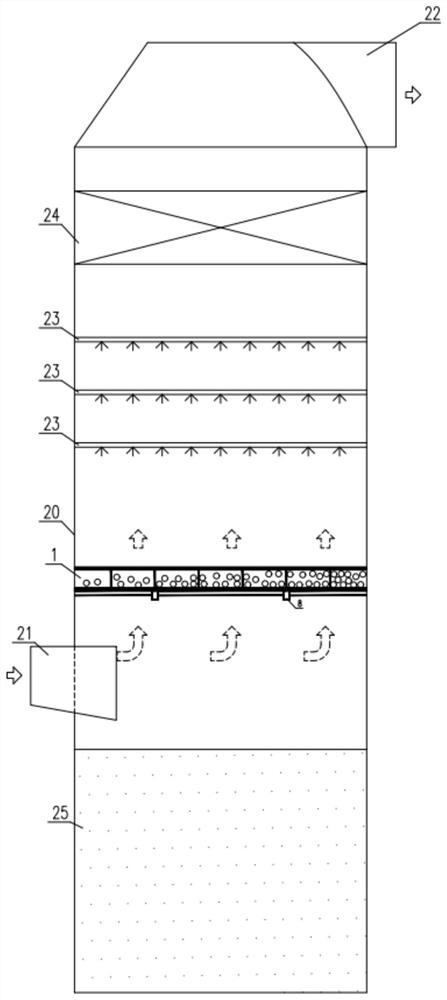

[0044] Main structure of the present invention and working process description:

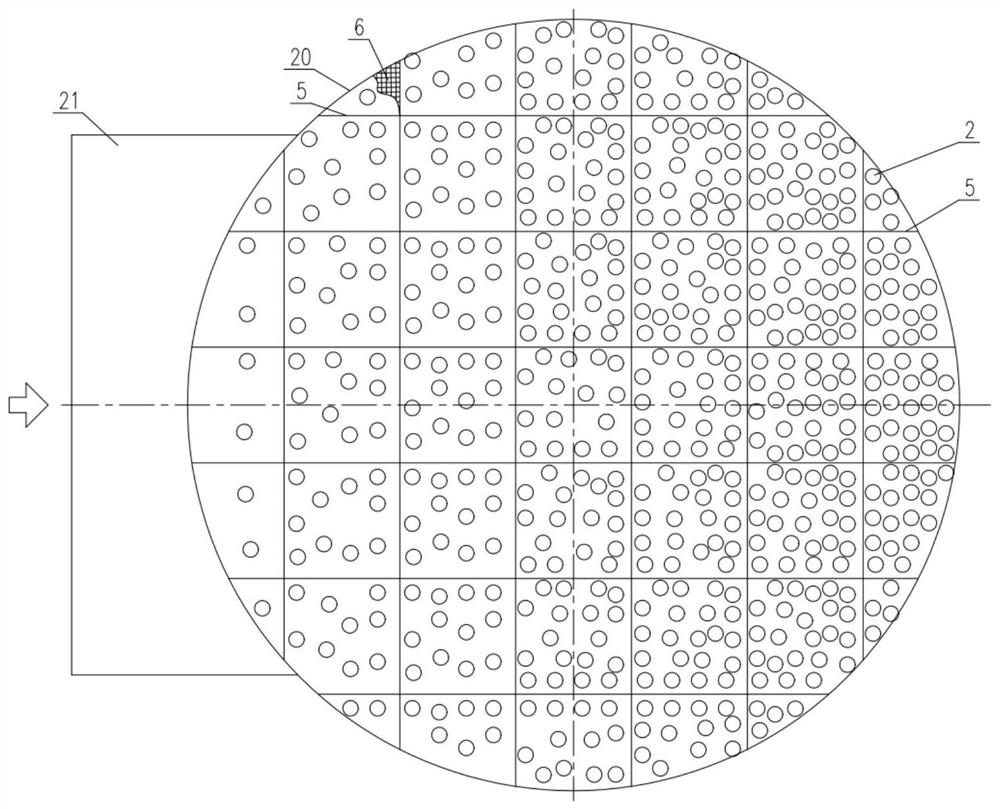

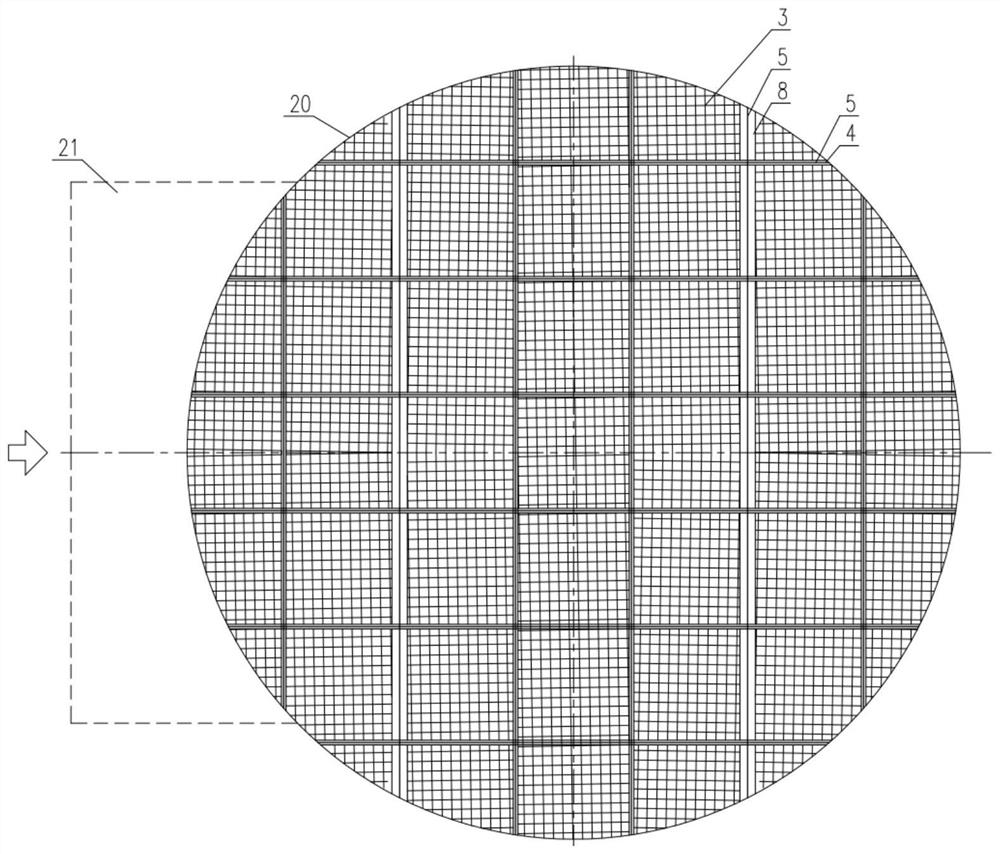

[0045] After the flue gas enters the absorption tower through the horizontal absorption tower inlet flue 21, the drift flue gas moves upward. During the rising process of the flue gas, the air flow is homogenized after passing through the flue gas equalization device, and the flue gas purification process is continued upwards. The present invention includes support beams, lower supporting grids and lower sealing nets, compartment partitions and flow equalizing balls, upper sealing nets and upper supporting grids, and connecting accessories from bottom to top (along the direction of airflow movement).

[0046] 1. The main functions of each component:

[0047] (1) Supporting beam: mainly used to support the whole flue gas flow equalization device, generally one or more heels are provided, and the specific design is based on different tower diameters.

[0048] (2) Lower support grid: mainly used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com