Preparation method of red mud-based catalyst for biomass pyrolysis

A biomass pyrolysis and catalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low yield and poor quality of pyrolysis oil, and reduce dependence, The effect of reducing costs, reducing waste of resources and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

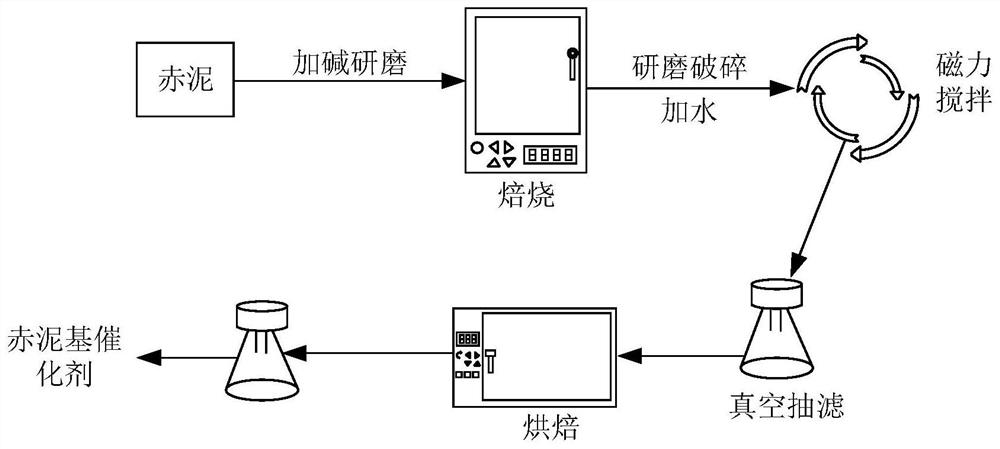

[0052] The preparation method of the red mud-based catalyst used for biomass pyrolysis of the present invention comprises the following steps:

[0053] Take 30g of pretreated Bayer process red mud, weigh 1.5 times the weight of solid NaOH of the red mud, that is, 45g of solid NaOH, put the two into a mortar and mix and grind until no obvious NaOH solid is visible to the naked eye, and prepare A number of 25ml crucibles are used to hold the mixture of red mud and NaOH, which are sent to the muffle furnace for roasting. The roasting temperature is 500°C, and the roasting time is 35 minutes. Take it out of the muffle furnace in time. After cooling to room temperature, it will be sintered The resulting dark green solid was crushed and ground to below 20 mesh, and 600ml of deionized water was added to form a red mud-alkali solution. The red mud-alkali solution was continuously stirred at a speed of 300r / min for 2 hours with a magnetic stirrer. After stirring, the red mud-alkali solu...

Embodiment 2

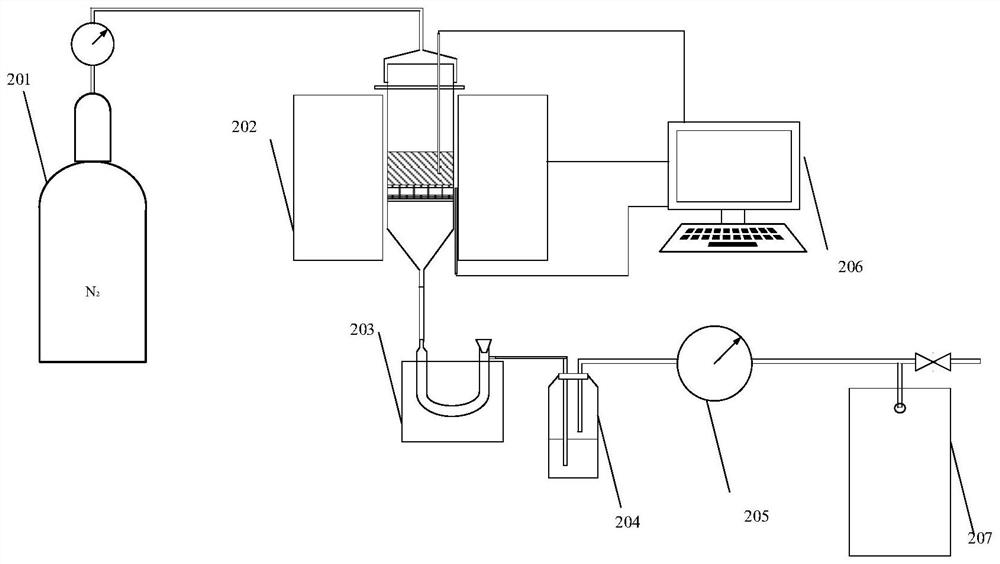

[0055] This embodiment is an example of the red mud-based catalyst prepared by the present invention being used for biomass pyrolysis, including the following steps:

[0056] The biomass used in the biomass pyrolysis experiment is corn stalks. The pyrolysis temperature is 600°C, including blank experiments. The biomass pyrolysis heating method is electric heating. The average value of 3 experiments is taken, including the following steps:

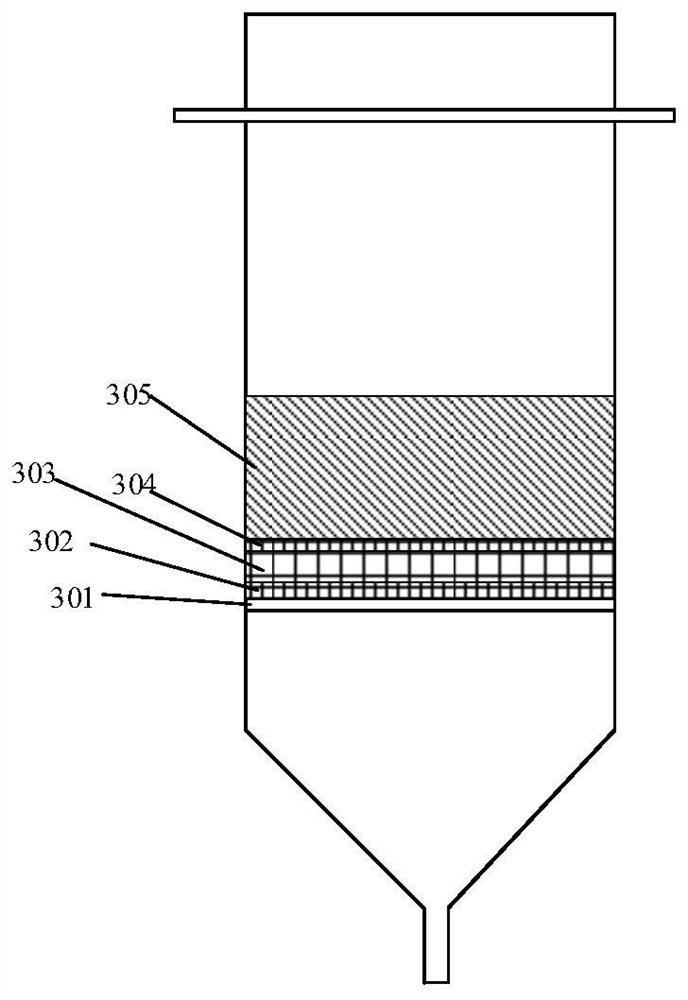

[0057] Get 5g of quartz sand that has been pulverized to below 20 meshes, then weigh 3 times its mass of biomass, i.e. 15g of biomass, take a certain amount of second quartz wool 302 and place it on the sintering plate 305 of the electric heating device 202, Weigh 5g of quartz sand and put it on the second quartz wool 302, and spread it flat. The quartz wool can effectively prevent the upper layer of quartz sand from flowing into the lower pipeline from the sintering plate, and then take a certain amount of first quartz wool 304 to pad on t...

Embodiment 3

[0061] This example is another example of the red mud-based catalyst prepared by the present invention being used for biomass pyrolysis. The temperature is 600 ° C. The heating method for biomass pyrolysis is infrared heating. The average value of three experiments is taken, including the following steps:

[0062] Take 5g of the red mud-based catalyst prepared by the present invention, then weigh 3 times the biomass of the biomass, i.e. 15g of biomass, take a certain amount of second quartz wool 302 and place it on the sintering plate 305 of the electric heating device 202. Weigh 5g of the red mud-based catalyst 303 and place it on the second quartz wool 302, spread it flat, the quartz wool can effectively prevent the red mud-based catalyst from flowing into the lowering pipeline, and then take a certain amount of the first quartz wool 304 to pad on the red mud-based On the catalyst 303, the biomass 301 is separated from the red mud-based catalyst 303, which is beneficial to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com