A kind of bismuth oxide/defective bismuth iodide composite material, preparation method and application thereof

A composite material, bismuth iodide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, oxidized water/sewage treatment, etc., can solve the problem of low photocatalytic activity, low separation efficiency, difficult Activation of persulfate and other problems, to achieve the effect of high degradation efficiency, simple preparation process, and improved photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The invention provides a preparation method of bismuth oxide / deficient iodine oxybismuth composite material, the preparation method comprising the following steps:

[0049] Step S1: Bi(NO 3 ) 3 ·5H 2 O dissolved in HNO 3 solution, and then add lye to adjust the pH to neutral, heat and stir for a period of time to obtain a mixed solution.

[0050] In a specific embodiment of the present invention, in step S1 Bi(NO 3 ) 3 ·5H 2 O and HNO 3 The molar ratio is 1:(10~20) (such as 1:10, 1:11, 1:12, 1:13, 1:14, 1:15, 1:16, 1:17, 1:18, 1 :19, 1:20), HNO 3 The concentration of the solution is 2mol / L.

[0051] In a specific embodiment of the present invention, the heating temperature in step S1 is 80-85°C (such as 80°C, 81°C, 82°C, 83°C, 84°C, 85°C), and the stirring time is 30-60min (such as 30min , 35min, 40min, 45min, 50min, 55min, 60min).

[0052] Step S2: Transfer the mixed solution obtained in step S1 to an autoclave for reaction, then cool to room temperature, wa...

Embodiment 1

[0067] This embodiment provides a preparation method of bismuth oxide / deficient iodine oxybismuth composite material, comprising the following steps:

[0068] Step S1: 1.94g (4mmol) Bi(NO 3 ) 3 ·5H 2 O dissolved in 2mol / L HNO 3 solution (26 mL), and then added NaOH (2.8 g) to adjust the pH to neutral, and stirred at 80° C. for 30 min to obtain a mixed solution 1.

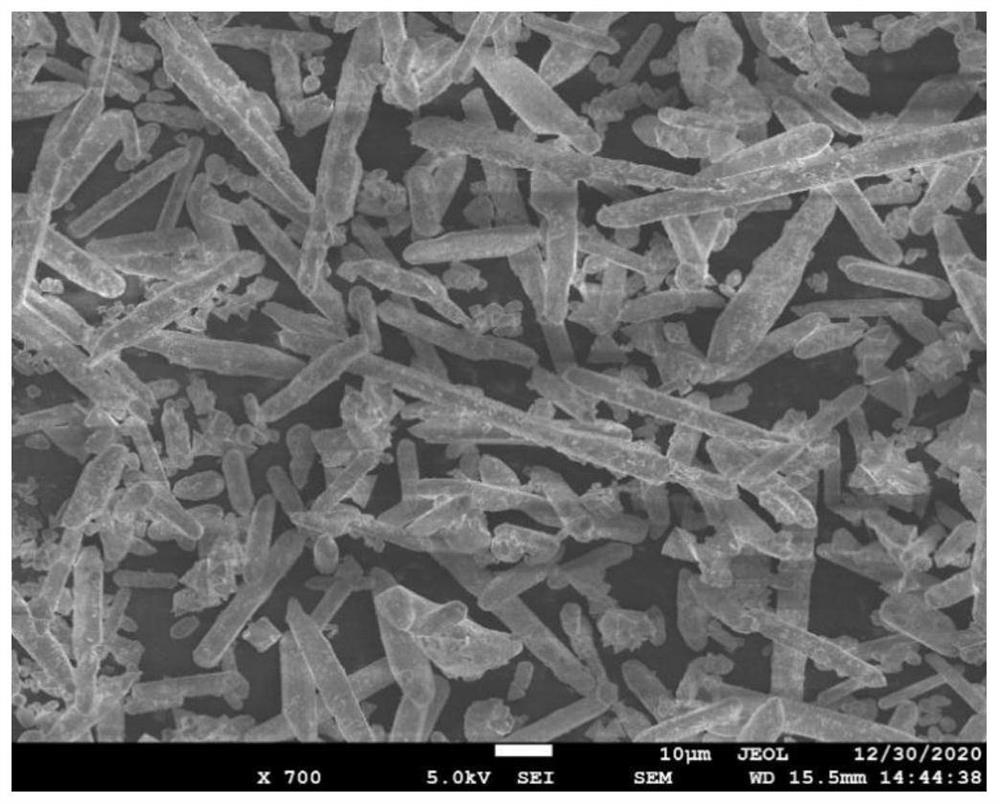

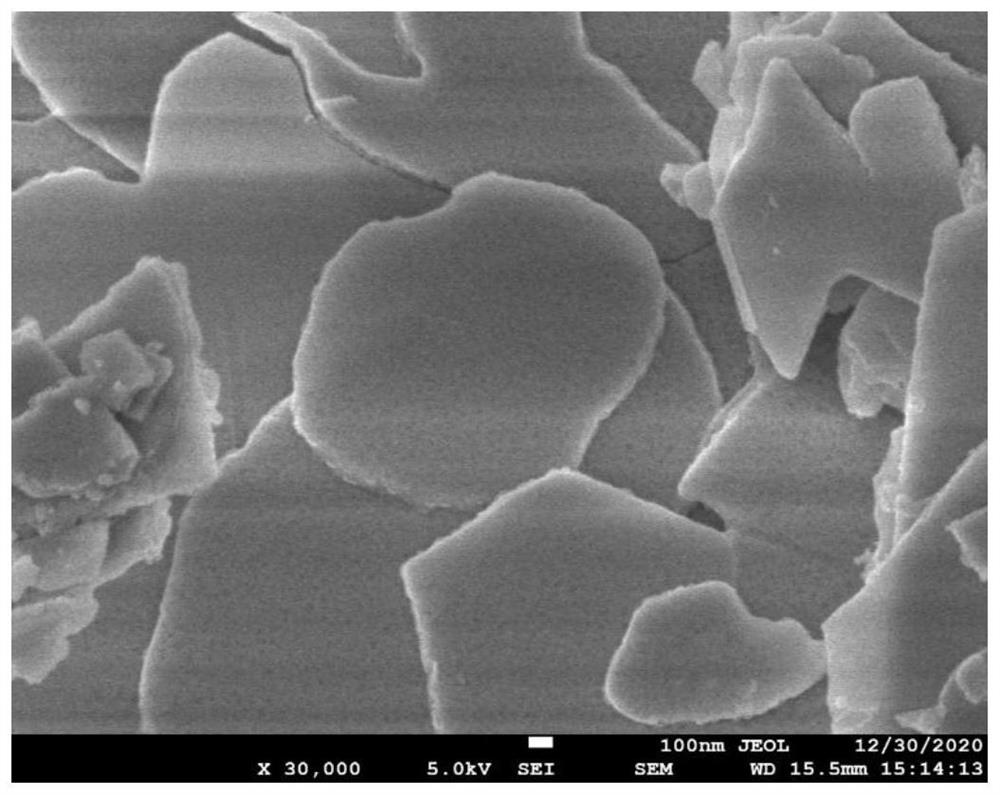

[0069] Step S2: Transfer the mixed solution obtained in Step S1 to an autoclave, react at 200° C. for 10 h, then cool to room temperature, wash and dry to obtain Bi 2 o 3 powder.

[0070] Step S3: 0.486g (1mmol) Bi(NO 3 ) 3 ·5H 2 O and the 1.095g Bi obtained in step S2 2 o 3 Add the powder into a mixed solution of 19.5 mL of water and 19.5 mL of ethylene glycol, stir at room temperature for 1 h to dissolve, then add 2 mol / L KI solution (1 mL) dropwise, and continue stirring for 30 min to obtain a mixed solution 2.

[0071] Step S4: Transfer the mixed liquid 2 obtained in step S3 to a hydrothermal reaction...

Embodiment 2

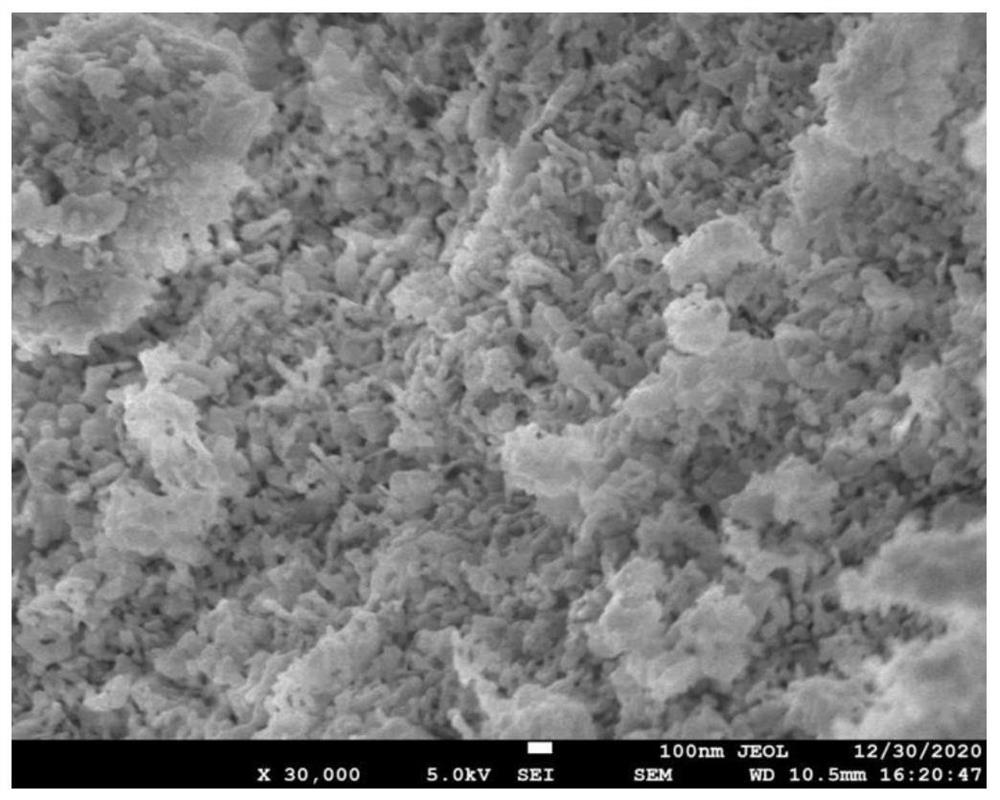

[0079] This embodiment provides a method for preparing a bismuth oxide / deficient iodine oxybismuth composite material. The difference between this preparation method and Example 1 is that in step S3, Bi 2 o 3 The amount of powder is 0.200g, and other steps and methods are the same as in Example 1, and will not be repeated here.

[0080] Bismuth oxide (Bi 2 o 3 ) and defective bismuth oxyiodide (BiO 1.4 I 0.3 ) in a molar ratio of 3:7.

[0081] Add the bismuth oxide / deficient bismuth iodine oxybismuth composite material prepared in this example with a molar ratio of 3:7 into the water polluted by propranolol, and then add 0.4mmol / L persulfate to the water body, the results show , under visible light, the bismuth oxide / deficient bismuth oxyiodide composite with a molar ratio of 3:7 has a significant effect on the degradation of propranolol in water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com