Continuous flow step-feed short-cut denitrification-anaerobic ammonia oxidation coupling denitrification sewage treatment system and method

A technology of anaerobic ammonium oxidation coupling and sewage treatment system, applied in biological water/sewage treatment, special compound water treatment, water/sludge/sewage treatment, etc., can solve the economic constraints of sewage plants and the impact of nitrite nitrogen Larger, high concentration of total nitrogen in effluent, easy to upgrade and optimize regulation, solve the problem of carbon source shortage, increase biomass and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

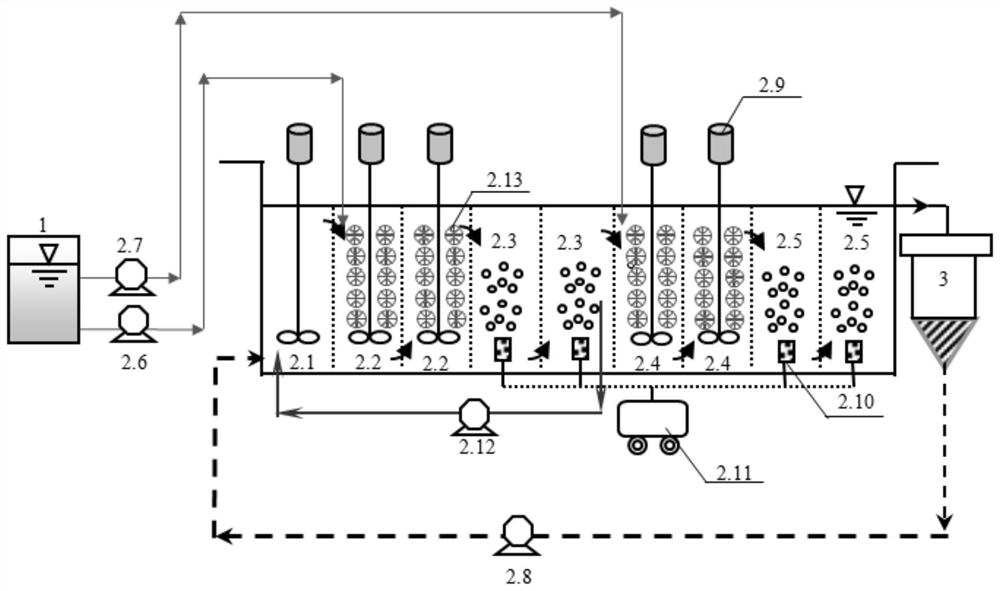

[0068] This embodiment provides a continuous flow segmented influent short-range denitrification-ANAMMOX coupled denitrification sewage treatment system, such as figure 1 As shown, the system includes a primary settling tank 1, a bioreactor and a secondary settling tank 3 connected in sequence;

[0069] The bioreactor comprises a pre-starvation zone 2.1, a first anoxic zone 2.2, a first aerobic zone 2.3, a second anoxic zone 2.4 and a second aerobic zone 2.5; the pre-starvation zone 2.1, the first anoxic zone Zone 2.2, the first aerobic zone 2.3, the second anoxic zone 2.4 and the second aerobic zone 2.5 are sequentially connected through a partition with a through hole on the upper part; the pre-starvation zone 2.1, the first anoxic zone 2.2, the second The first aerobic zone 2.3, the second anoxic zone 2.4 and the second aerobic zone 2.5 all include two compartments, and each compartment is connected by a partition with a through hole in the lower part.

[0070] Stirrers 2....

Embodiment 2

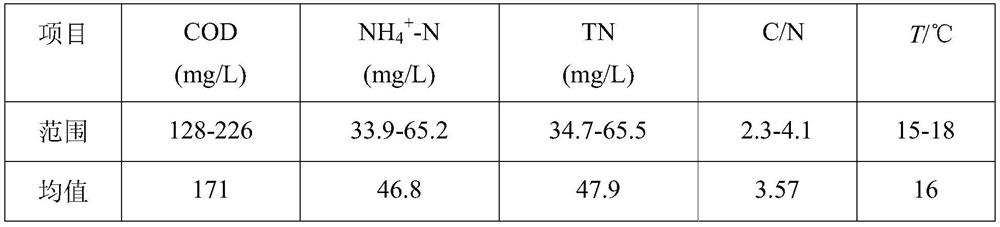

[0080] This embodiment provides a continuous-flow segmented influent short-range denitrification-anammox coupled denitrification sewage treatment method, which uses the continuous-flow segmental influent short-range denitrification-anammox coupled denitrification sewage treatment system described in Example 1 , the sewage is the primary sinking water of a certain urban sewage treatment plant. After testing, the water quality of the urban sewage is shown in Table 1.

[0081] Table 1 Urban sewage water quality

[0082]

[0083] Including the following steps:

[0084] S1: introduce the sewage into the primary sedimentation tank 1 and control the temperature of the primary sedimentation tank 1 to 25°C, inoculate short-range denitrifying bacteria in each cell of the bioreactor, and The first anoxic zone 2.2 and the second anoxic zone 2.4 are inoculated with anammox bacteria, the anammox bacteria are arranged on the polyurethane sponge filler 2.13, and the total nitrogen removal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap