Electroplating wastewater pretreatment integrated equipment

A technology for electroplating wastewater and pretreatment, applied in water/sewage treatment equipment, metallurgical wastewater treatment, multi-stage water treatment, etc., can solve the problems of high investment cost, large floor space, inconvenient maintenance, etc. Small footprint and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

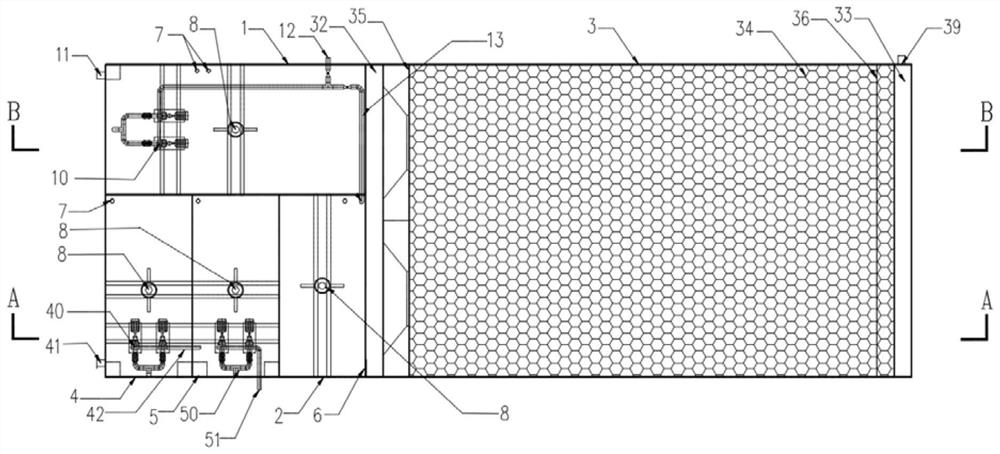

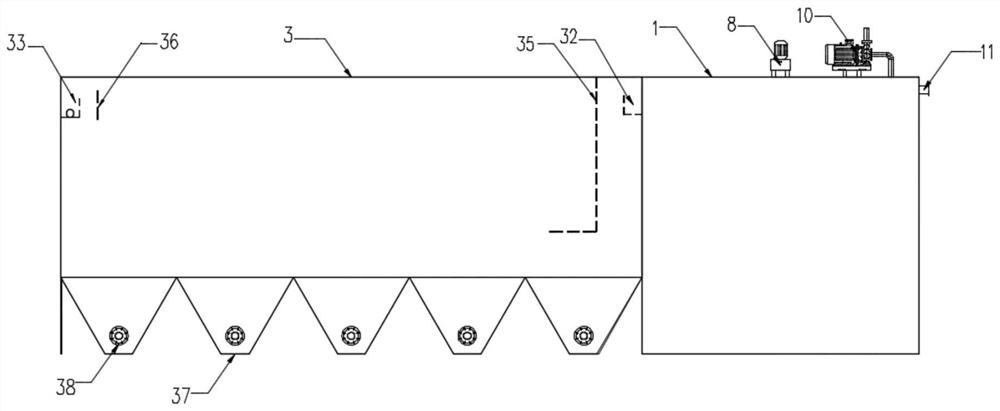

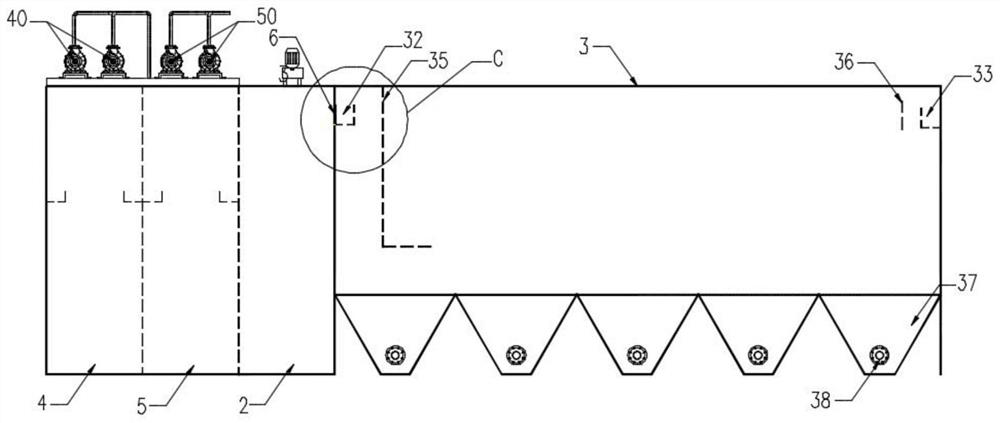

[0026] Please refer to Figure 1-Figure 7 , the present invention provides an integrated equipment for pretreatment of electroplating wastewater, comprising: a coagulation reaction tank 1, a coagulation flocculation tank 2, and a sedimentation tank 3 arranged in series in sequence; Cyanide breaking tank 4, secondary cyanide breaking tank 5; said coagulation reaction tank 1, coagulation flocculation tank 2, primary cyanide breaking tank 4, and secondary cyanide breaking tank 5 are provided with dosing point 7, said The dosing point 7 is used to add lye (such as sodium hydroxide) and polyaluminium chloride to the coagulation reaction tank 1 by cooperating with the external dosing pump and the dosing pipeline, Add polyacrylamide, add lye (such as sodium hydroxide) and sodium hypochlorite to the primary cyanide breaking tank 4, add acid solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com