Thermal insulation bedding tile block based on nano aerogel particles and preparation method of thermal insulation bedding tile block

A nano-airgel and particle technology, which is applied in heat exchange equipment, heat-insulated protection pipes, mechanical equipment, etc., can solve the problems of destroying the overall heat preservation of steam pipes, fragile hard heat insulation blocks, and failure of anti-loose design , to achieve environmental safety, no radioactivity, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

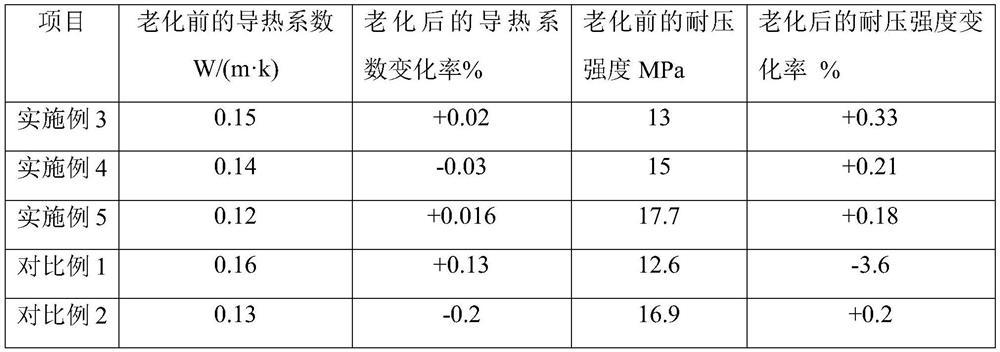

Examples

Embodiment 1

[0037] By spraying, once every 5 minutes, 2.5kg of isobutyltriethoxysilane was added to 100kg of silica airgel particles with a particle size of 4mm, and mixed for 1 hour at room temperature to obtain modified silica airgel. Gel particles.

Embodiment 2

[0039] Spray 1 kg of methyltrimethoxysilane into 100 kg of silica airgel particles with a particle size of 2 mm every 5 minutes, and mix for 1 hour at room temperature to obtain modified silica airgel particles .

Embodiment 3

[0041] A method for preparing a high-strength airgel thermal insulation tile, comprising the following steps:

[0042] (1) Preparation before preparation

[0043]1) The preparation environment should be clean and tidy to prevent dust from polluting the sample preparation process; the ambient temperature should be controlled between 5°C and 40°C, if the temperature is lower than 5°C, attention should be paid to antifreeze, and if the temperature is higher than 40°C, attention should be paid to cooling down.

[0044] 2) Prepare the equipment. Before the preparation, you must check whether the bolts in the equipment are firm, whether the circuit is safe, and whether the equipment is noisy.

[0045] 3.) Water, rust, oil, slag and other debris on the equipment must be removed before construction, so as not to affect the strength of the material;

[0046] (2) The preparation method of airgel thermal insulation tile;

[0047] (1) Ratio of material (both mass ratio)

[0048] 1) A:B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com