Sintering method of harmful dust and sludge in iron and steel plant

A sintering method and technology of iron and steel plants, applied in the field of sintering, can solve the problems affecting the sintering index and metallurgical properties, and achieve the effect of strong operability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

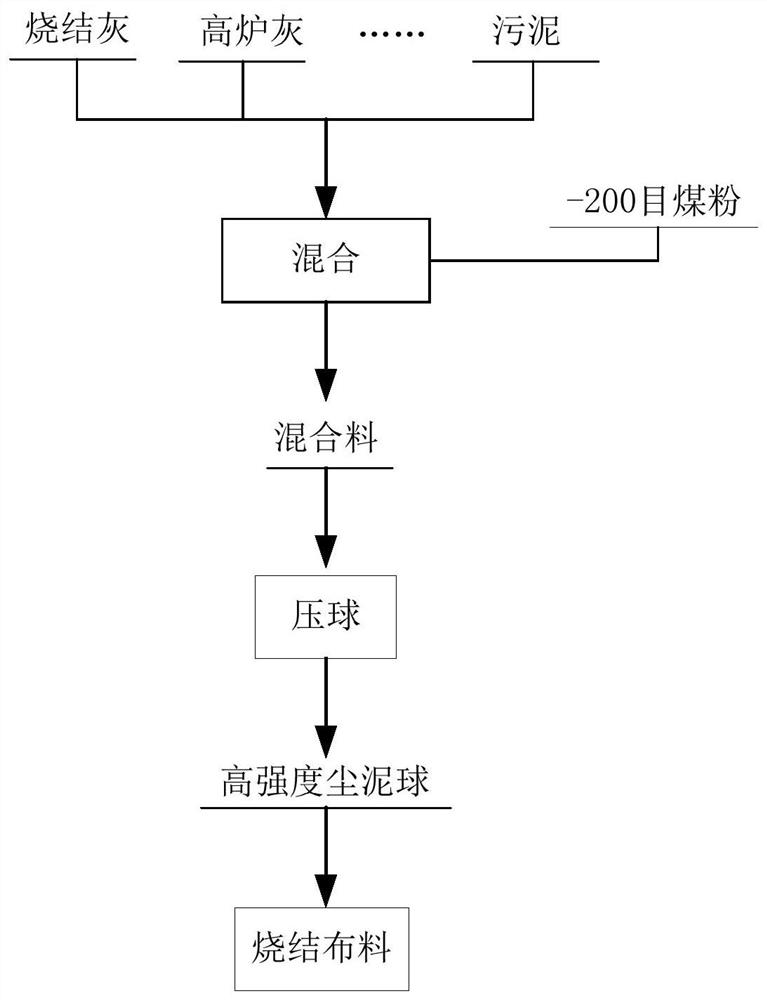

Method used

Image

Examples

Embodiment 1

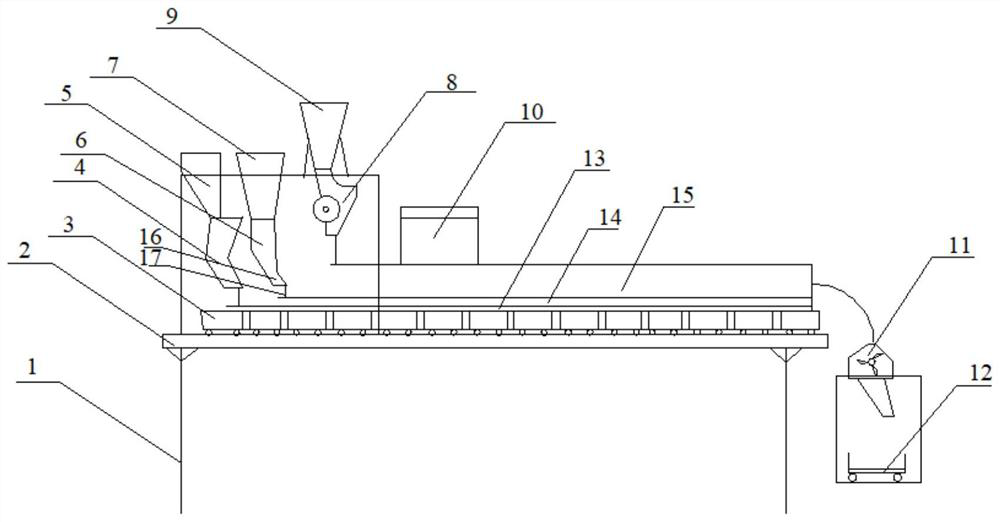

[0040] as attached figure 2 The above is a schematic structural view of a sintering machine according to an embodiment of the present invention. A sintering lane 2 is provided on the frame 1 of the sintering machine, and a sintering trolley 3 is arranged on the sintering lane 2. The sintering trolley 3 includes a trolley body and It is arranged on the material blocking plates on both sides of the trolley body.

[0041] On the sintering driveway 2, from the head to the tail, the material spreading mechanism I4, the dust ball spreading mechanism II6, the sintering raw material distributor 8 and the igniter 10, as well as the sintering ventilation system and the unloading device are arranged in sequence. There are crushers 11 and conveyors 12 below. The upper end of the discharge port of the dust ball spreading mechanism II6 is connected to the dust ball bin 7, the upper end of the dust ball spreading mechanism I4 is connected to the bottom bunker 5, and the top of the sinterin...

Embodiment 2

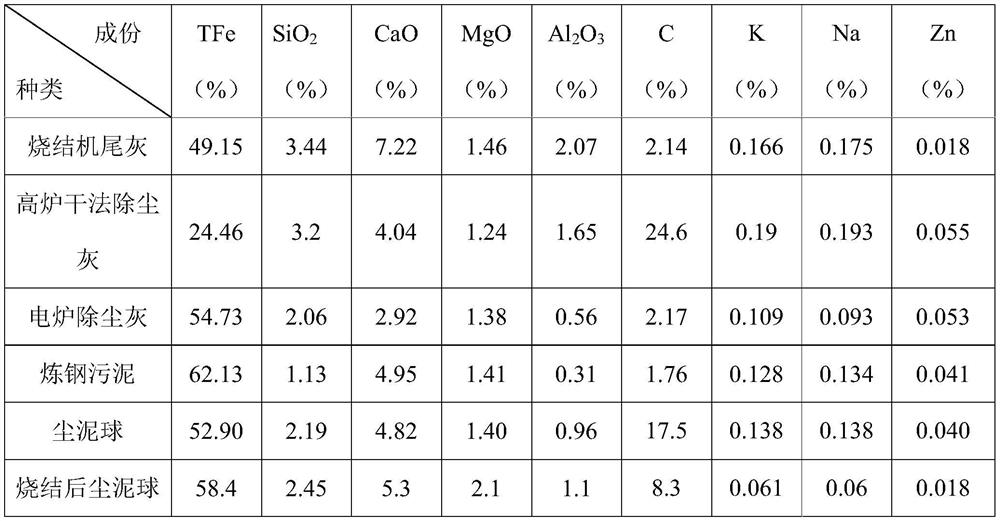

[0056] A sintering method for harmful dust sludge in iron and steel works, the method utilizes the sintering machine described in embodiment 1, and the dust sludge mixture in iron and steel enterprises includes shaft furnace dedusting ash, blast furnace dry dedusting ash, steelmaking coarse ash, and dedusting under the upper and lower troughs The composition of ash and steelmaking sludge is shown in Table 3 below.

[0057] Shaft furnace dedusting ash, blast furnace dry dedusting ash, steelmaking coarse ash, upper and lower trough dedusting ash, and steelmaking sludge are mixed at a ratio of 0.3:0.15:0.1:0.25:0.2 on a dry basis, respectively. Among them, Fe is all Fe 2 o 3 In terms of existing forms, K, Na, and Zn are represented by K 2 O, Na 2 O, ZnO meter. Coal powder is added according to the content of oxygen in the oxides of C and TFe, K, Na and Zn in the dust-sludge mixture to obtain a dust-slag mixture. The amount of pulverized coal added is to control the molar rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com