Systems and methods for determining characteristics of semiconductor devices

A technology for semiconductors and devices, applied in the field of systems and methods for determining the characteristics of semiconductor devices, capable of solving problems such as major obstacles not being overcome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0237] first part

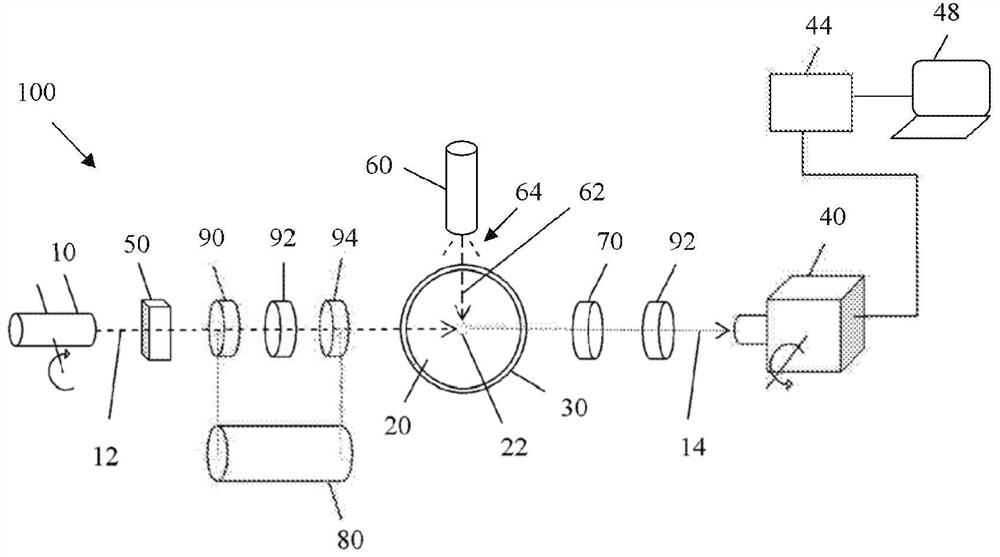

[0238] Figure 1 is a schematic diagram of a system 100 that may be used in conjunction with the methods of the present invention. For example, for intermediate optical elements, including optical delay lines and optional electrode features, in U.S. Provisional Application No. 61 / 980,860, filed April 17, 2014, entitled "WAFERMETROLOGY TECHNOLOGIES" Other suitable system variations are set forth in the section entitled "CHARGE DECAY MEASUREMENT SYSTEMS AND METHODS" referred to as Section II.

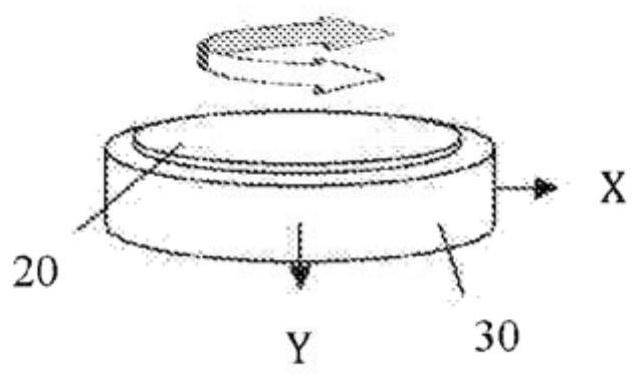

[0239] As shown, system 100 includes a primary or probe laser 10 for directing an interrogation beam 12 of electromagnetic radiation onto a sample wafer 20 held by a vacuum chuck 30 . Such as Figure 1BAs shown, the chuck 30 includes, or is disposed on, an x-stage and a y-stage, and optionally, the chuck also includes a rotary table for adjusting the position relative to the laser aiming position. Spots 22 are located on the wafer. The x-y stage enables scanning o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com