Surface-modified MBBR suspended carrier and application

A suspension carrier and surface modification technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as easy dissociation, and achieve improved hydrophilicity and wear resistance Good performance and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

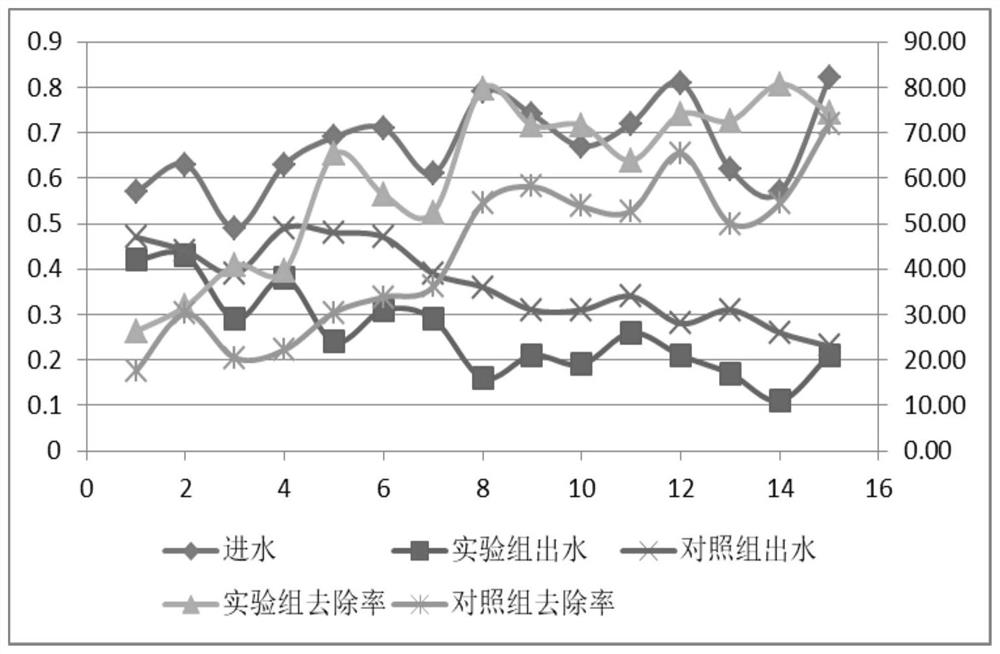

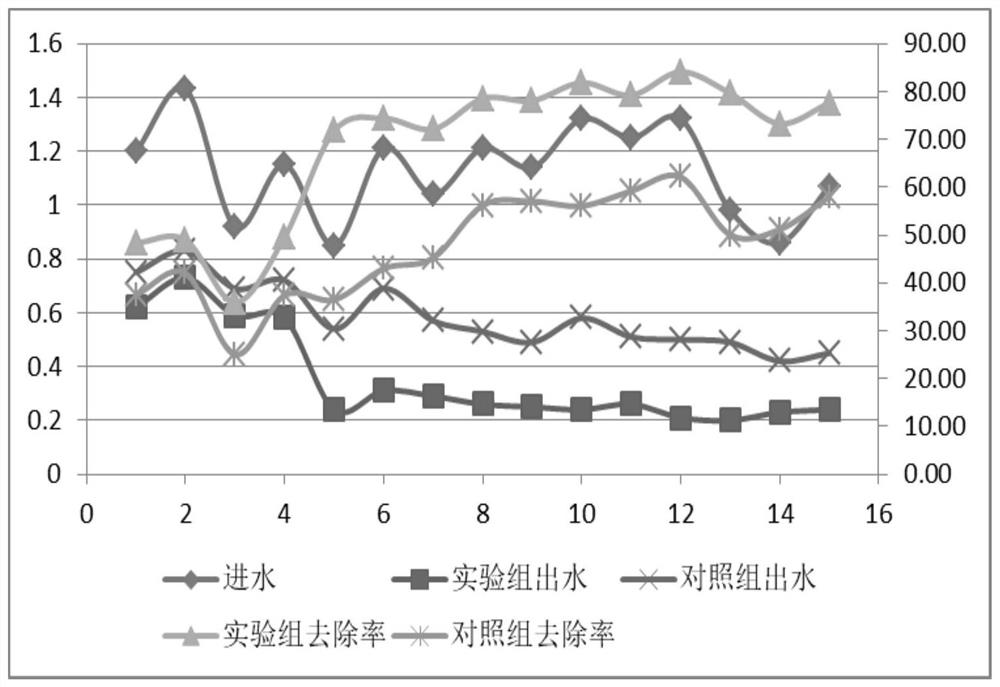

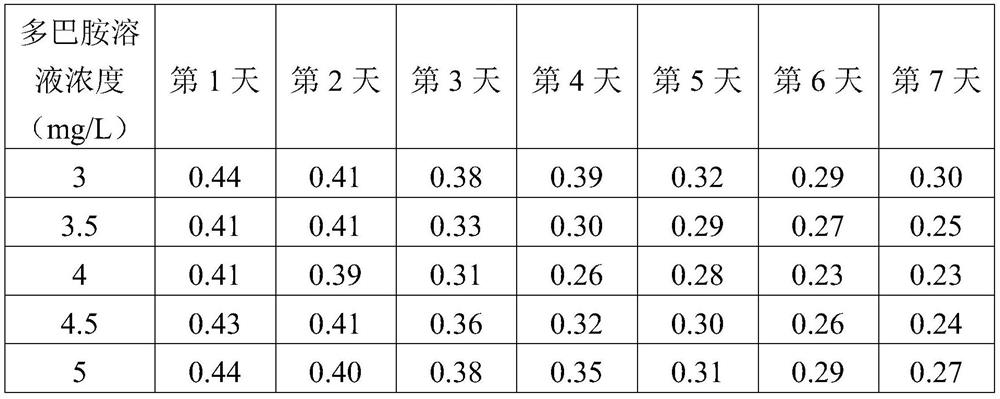

[0033] (1) Add dopamine to the Tris-HCl buffer solution with a pH of 8.5 and a concentration of 10mmol / L, and prepare dopamine with a concentration of 3mg / L, 3.5mg / L, 4mg / L, 4.5mg / L, and 5mg / L respectively solution.

[0034] (2) Change the model to Place the MBBR suspension carrier in the dopamine solution, make the surface of the MBBR suspension carrier fully and uniformly contact the dopamine solution, stir at 120rpm for 30min, stir once every 4h, stirring can make the air dissolve into the solution, the total soaking time is 24h, and repeat with distilled water Wash several times and dry naturally to obtain the dopamine-modified MBBR suspension carrier.

[0035] (3) The dopamine surface-modified MBBR suspension carrier was placed in a phosphate buffer solution with a pH of 3.0, soaked for 30 minutes, and protonated. After taking it out, it was repeatedly washed with distilled water several times, and dried naturally to obtain a protonated dopamine surface-modified MBBR s...

Embodiment 2

[0041] (1) preparation pH is 7.5, 8.5, 9.5 respectively, the Tris-HCl damping fluid that concentration is 10mmol / L, then adds dopamine respectively in the Tris-HCl damping fluid of different pH, gets concentration and is 4mg / L but Dopamine solutions with different pH

[0042] Then add dopamine to the Tris-HCl buffer respectively, and stir at 120 rpm for 20 min to completely dissolve the dopamine in the solution to obtain a concentration of .

[0043] (2) Change the model to Place the MBBR suspension carrier in the dopamine solution, make the surface of the MBBR suspension carrier fully and evenly contact the dopamine solution, stir at 120rpm for 30min, and stir once every 4h. The stirring can make oxygen dissolve into the solution. The total soaking time is 24h, and it is repeated with distilled water. Wash several times and dry naturally to obtain the dopamine-modified MBBR suspension carrier.

[0044] (3) The dopamine surface-modified MBBR suspension carrier was placed in...

Embodiment 3

[0050] (1) Dopamine was added to a Tris-HCl buffer solution with a pH of 8.5 and a concentration of 10 mmol / L to prepare a dopamine solution with a concentration of 4 mg / L.

[0051] (2) Change the model to Place the MBBR suspension carrier in the dopamine solution, make the surface of the MBBR suspension carrier fully and uniformly contact the dopamine solution, stir at 120rpm for 30min, every 2h, 4h, 6h, 8h, stir to dissolve oxygen into the solution, and the total soaking time is 24h , washed several times with distilled water, and dried naturally to obtain the dopamine-modified MBBR suspension carrier.

[0052] (3) The dopamine surface-modified MBBR suspension carrier was placed in a phosphate buffer solution with a pH of 3.0, soaked for 30 minutes, and protonated. After taking it out, it was repeatedly washed with distilled water several times, and dried naturally to obtain a protonated dopamine surface-modified MBBR suspension carrier, that is, a surface-modified MBBR su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com