Production system and method of refined diesel oil

A technology for refining diesel oil and feedstock oil, which is applied in the fields of refining hydrocarbon oil, mixing methods, hydrocarbon oil treatment products, etc., can solve the problems of high pressure in the hydrogenation reactor, large consumption of circulating hydrogen and high temperature, and achieves low reaction temperature, The effect of reducing energy consumption and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

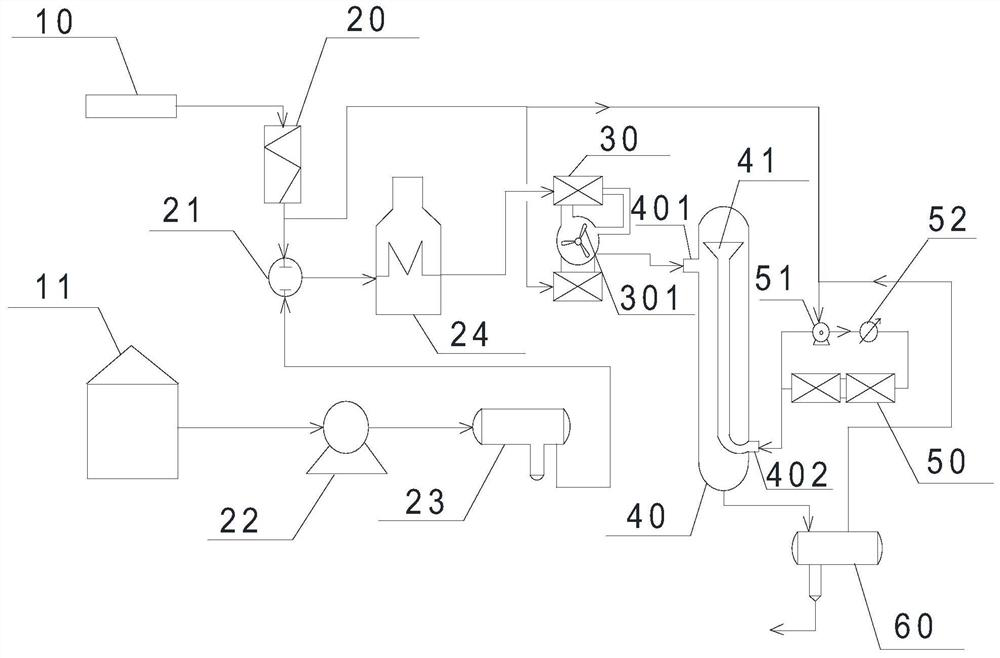

[0053] refer to figure 1 As shown, it is a schematic structural diagram of a refined diesel production system provided by an embodiment of the present invention, which mainly includes a hydrogen gas intake pipeline 10, a crude oil tank 11, a fluidized bed reactor 40, and a first external micro-interface unit 30 , The second external micro-interface unit 50 and the separator 60.

[0054] The raw material oil from the raw material tank first passes through the raw material booster pump 22, which can increase the flow rate of the raw material in the production system and prevent the raw material from coking in the pipeline of the production system, the fluidized bed reactor 40 or other reactors and affect the reaction rate. After passing through the raw material booster pump 22, the raw material oil enters the raw material buffer tank 23. The raw material buffer tank 23 can control the pressure in the system and alleviate the problems such as explosion due to excessive pressure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com