Steel-alkali-activated UHPC composite structure, prefabricated alkali-activated UHPC board and connecting piece

A combined structure and alkali-activated technology, which is applied to bridge parts, buildings, bridges, etc., can solve the problems of low service life of steel-concrete combined structures, and achieve the effects of environmental protection, prolonging the practical life, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further explain the technical means and effects adopted by the present invention to achieve the intended invention goal, the steel-alkali excited UHPC composite structure proposed according to the present invention, its specific implementation, features and effects are described in detail below.

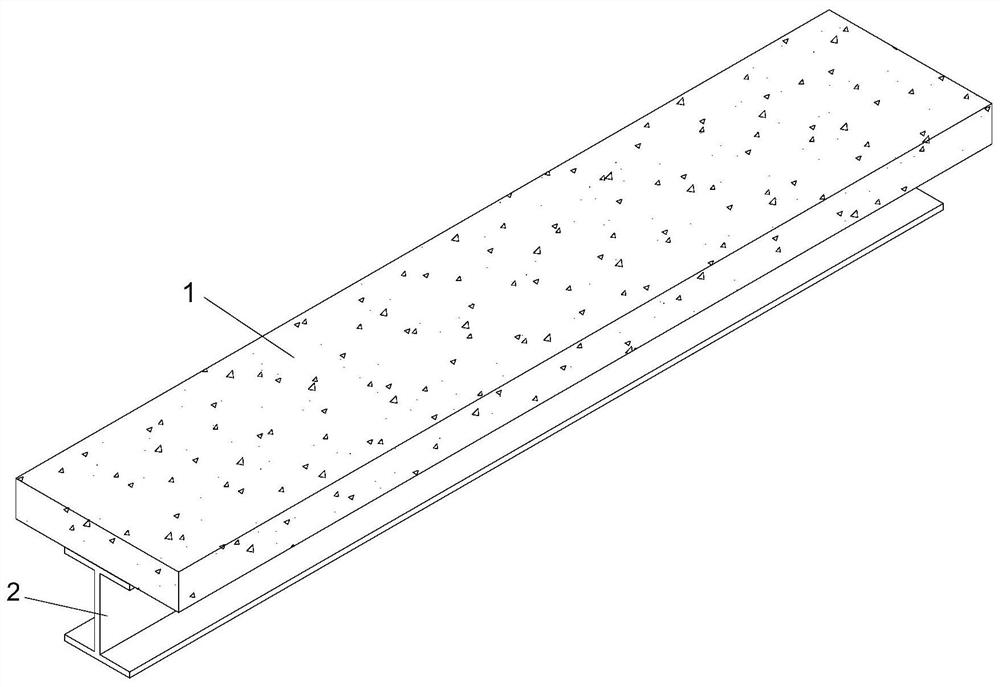

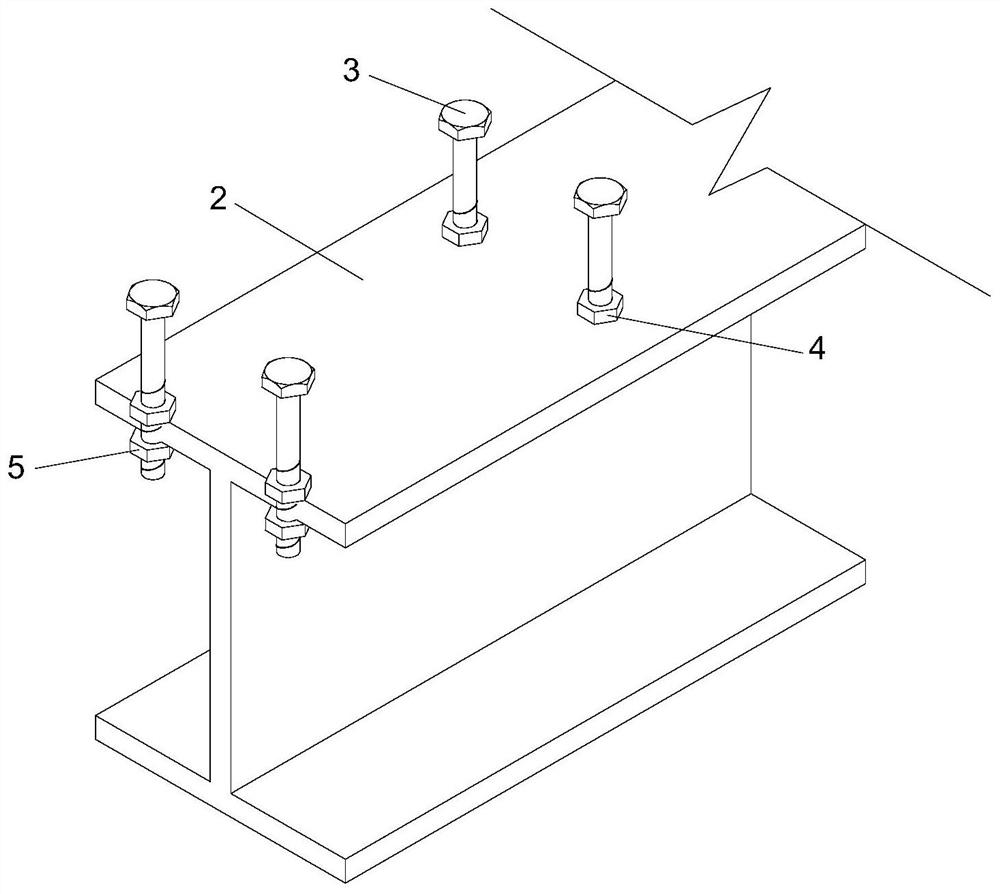

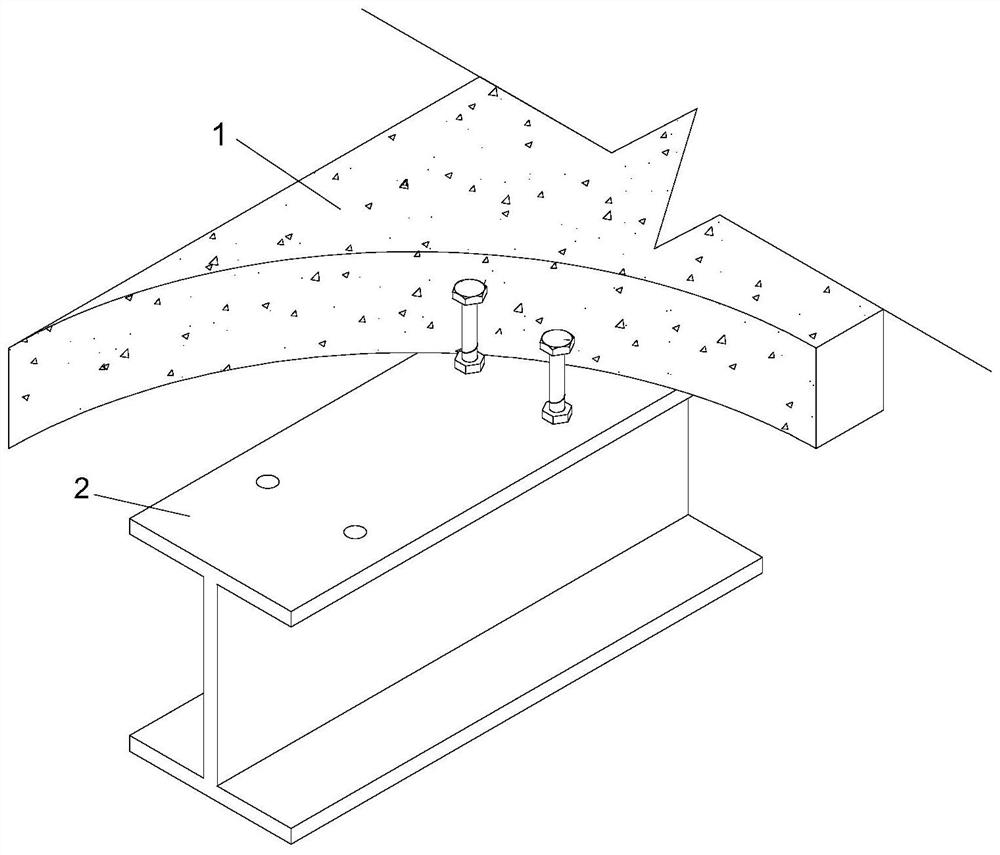

[0029] refer to Figure 1-Figure 5 , a steel-alkali-inspired UHPC composite structure, comprising a steel beam 2 and a prefabricated alkali-inspired ultra-high performance concrete slab 1 covering the steel beam, and the steel beam and the prefabricated alkali-inspired ultra-high performance concrete slab are pre-embedded Shear connector connections in concrete slabs.

[0030] Further, both sides of the upper flange plate of the steel beam 2 are respectively provided with long round holes for the high-strength bolts 3 to pass through, and the number and spacing of the round holes are related to the span and width of the steel beam.

[0031] Further, the shear conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com