Solar cell module

A technology of solar cells and modules, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as secondary pollution, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Physical property test of solar cell module (thermoplastic resin layer is hydrogenated styrene resin, thickness 200μm)

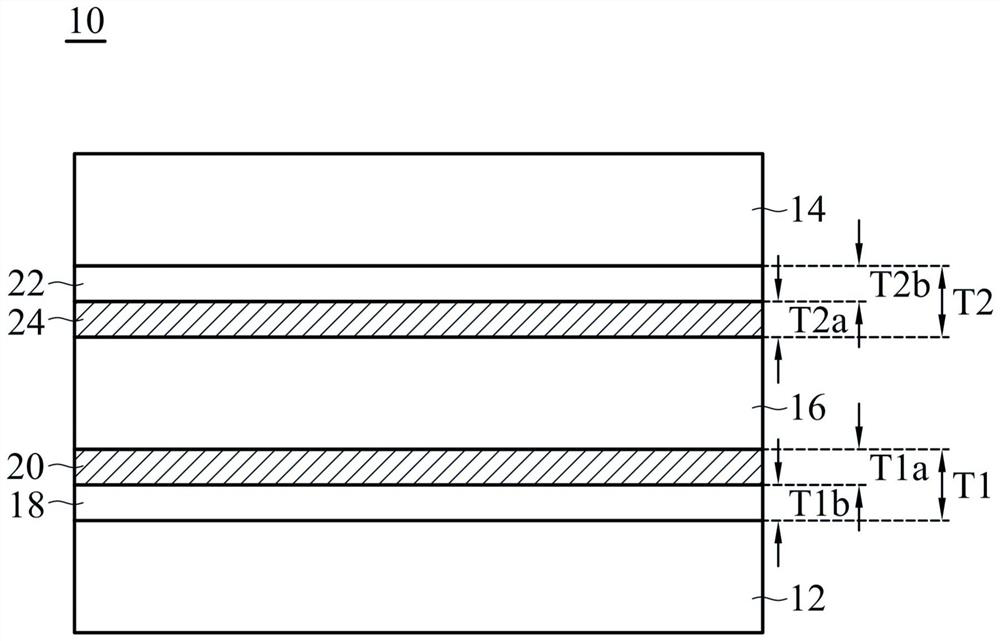

[0036] In this embodiment, as figure 1 The solar cell module 10 shown was subjected to physical property tests. In the module structure, the materials and dimensions of related components are described as follows: the first substrate (backplane) 12 is a solar backplane with a thickness of about 0.31 mm. The second substrate (front plate) 14 is transparent glass with a thickness of about 3.2 mm. The thickness of the battery cell 16 is approximately 180 μm. The first thermosetting resin layer 18 is ethylene-vinyl acetate copolymer (EVA) (SKC, EF2N) and has a thickness of about 400 μm. The first thermoplastic resin layer 20 is hydrogenated (styrene-butadiene-styrene) triblock copolymer (SEBS) (available from Asahi chemical Co. Ltd. S.O.E. TM S1611, glass transition temperature 9°C, melt fluidity 4g / 10min (190°C, 2.16kgf)), thickness about 292μm. The...

Embodiment 2

[0038] Physical property test of solar cell module (thermoplastic resin layer is hydrogenated styrene resin, thickness 400μm)

[0039] In this embodiment, as figure 1 The solar cell module 10 shown was subjected to physical property tests. In the module structure, the materials and dimensions of related components are described as follows: the first substrate (backplane) 12 is a solar backplane with a thickness of about 0.31 mm. The second substrate (front plate) 14 is transparent glass with a thickness of about 3.2mm. The thickness of the battery cell 16 is approximately 180 μm. The first thermosetting resin layer 18 is ethylene-vinyl acetate copolymer (EVA) (SKC, EF2N) and has a thickness of about 400 μm. The first thermoplastic resin layer 20 is hydrogenated (styrene-butadiene-styrene) triblock copolymer (SEBS) (available from Asahi chemical Co. Ltd. S.O.E. TM S1611, glass transition temperature 9°C, melt fluidity 4g / 10min (190°C, 2.16kgf)), thickness about 511μm. The ...

Embodiment 3

[0041] Physical property test of solar cell module (thermoplastic resin layer is acrylic resin)

[0042] In this embodiment, as figure 1 The solar cell module 10 shown was subjected to physical property tests. In the module structure, the materials and dimensions of related components are described as follows: the first substrate (backplane) 12 is a solar backplane with a thickness of about 0.31 mm. The second substrate (front plate) 14 is transparent glass with a thickness of about 3.2mm. The thickness of the battery cell 16 is approximately 180 μm. The first thermosetting resin layer 18 is ethylene-vinyl acetate copolymer (EVA) (SKC, EF2N) and has a thickness of about 400 μm. The first thermoplastic resin layer 20 is a tri-block acrylic resin (KURARAY, LA2140, melt fluidity: 31 g / 10 min (190° C., 2.16 kgf)), and its thickness is about 320 μm. The second thermosetting resin layer 22 is ethylene-vinyl acetate copolymer (EVA) (SKC, EF2N) and has a thickness of about 400 μm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com