Protein with cholesterol lowering effect and preparation method thereof

A cholesterol-lowering and effective technology, applied in the field of protein with cholesterol-lowering effect and its preparation, can solve the problems of high cost, time-consuming and labor-intensive, lack of scientificity and credibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

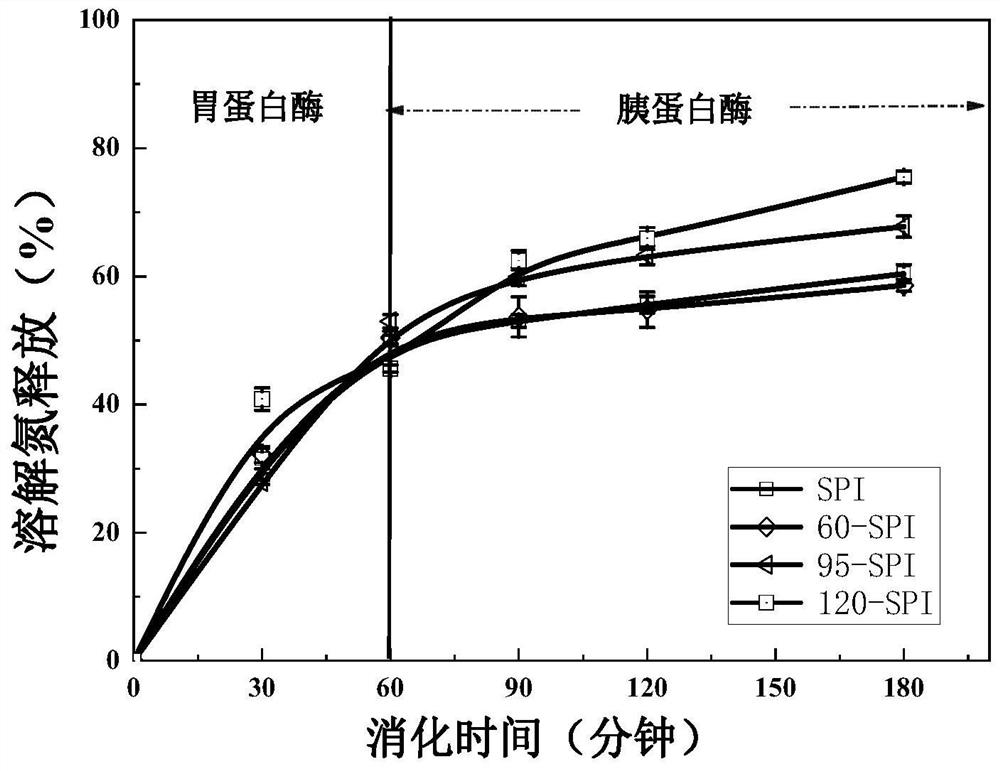

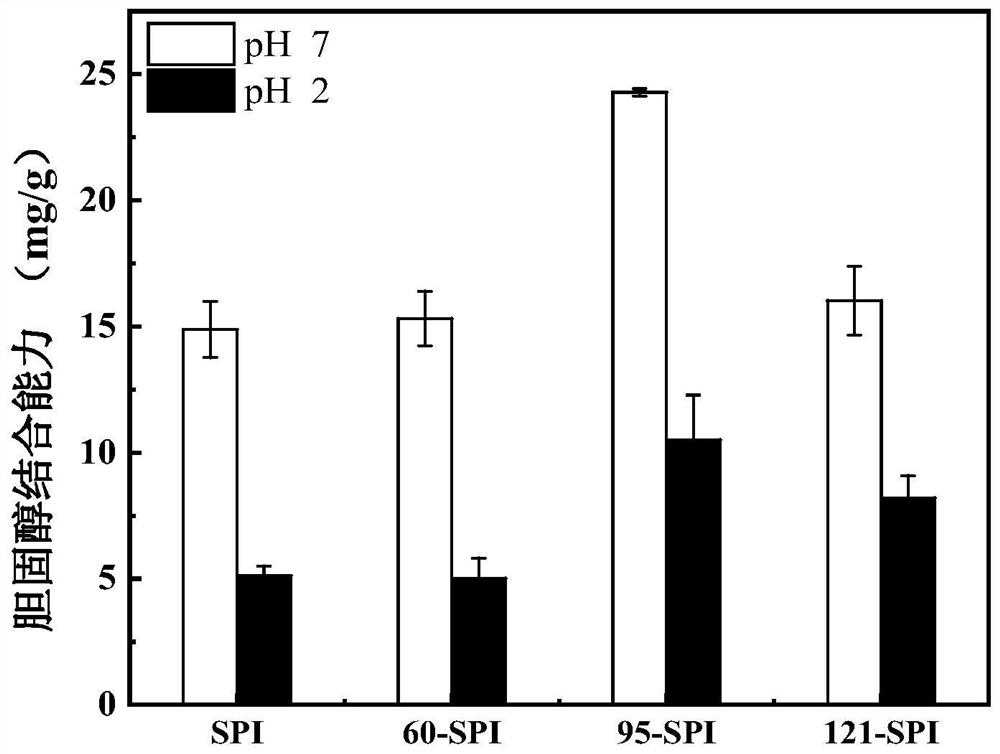

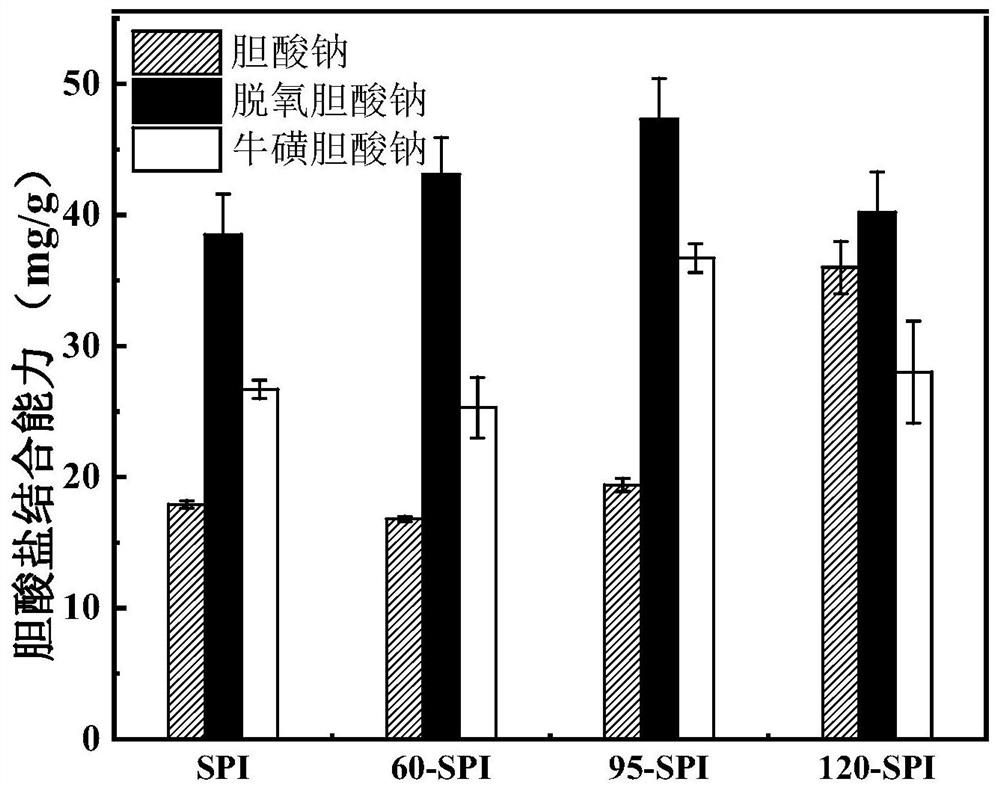

[0037] 1) Accurately weigh 5g of soybean protein isolate powder, disperse it in 100g of distilled water, adjust the pH to 7.0, stir continuously at room temperature (25°C) for 2h to dissolve completely, and then hydrate at 4°C for 12h , to obtain a concentration of 5wt% soybean protein isolate solution.

[0038] 2) Take out the soybean protein isolate solution in 1) and return to room temperature, centrifuge to remove insoluble matter to obtain a protein solution; heat the protein solution at a constant temperature of 60°C, 95°C and 120°C for 20 minutes, and then immediately ice-bath to make The temperature is returned to room temperature (25° C.), and the cooling rate is 3° C. / min to obtain a heat-pretreated soybean protein isolate dispersion.

[0039] 3) Centrifuge the heat-pretreated soybean protein dispersion obtained in 2) (5000 g, 10 min), and take the supernatant to obtain a clear solution.

[0040] 4) The clear solution obtained in 3) is freeze-dried to obtain a prote...

Embodiment 2

[0047] 1) Accurately weigh 5 soybean 11s protein powders, disperse them in 100g of distilled water, adjust the pH to 7.0, stir continuously at room temperature (25°C) for 2h to dissolve completely, and then hydrate at 4°C for 12h , to obtain a soybean 11s protein solution with a concentration of 5wt%.

[0048] 2) Take out the soybean 11s protein solution in 1), wait until it returns to room temperature, and centrifuge to remove insoluble matter to obtain a protein solution; heat the protein solution at a constant temperature of 60°C, 95°C and 120°C for 20 minutes, and then immediately ice-bath to make The temperature of the sample was brought to room temperature (25° C.), and the cooling rate was 3° C. / min to obtain a preheated soybean 11s protein dispersion.

[0049] 3) centrifuge (5000g, 10min) the heat-pretreated soybean 11s protein dispersion obtained in 2), and take the supernatant to obtain a clear solution.

[0050] 4) The clear solution obtained in 3) is freeze-dried ...

Embodiment 3

[0054] 1) Accurately weigh 5g of soybean 7s protein powder, disperse it in 100g of distilled water, adjust the pH to 7.0, stir continuously at room temperature (25°C) for 2h to dissolve completely, and then hydrate at 4°C for 12h to obtain a stock solution of soybean 7s protein with a concentration of 5wt%.

[0055] 2) Take out the soybean 7s protein solution in 1), wait until it returns to room temperature, and centrifuge to remove insoluble matter to obtain a protein solution; heat the protein solution at 60°C, 95°C and 120°C for 20 minutes at a constant temperature, and then immediately ice-bath to make After it is cooled to room temperature, the heat-pretreated soybean 7s protein dispersion is obtained.

[0056] 3) Centrifuge (5000g, 10min) the heat-pretreated soybean 7s protein dispersion obtained in 2), and take the supernatant to obtain a clear solution.

[0057] 4) The clear solution obtained in 3) is freeze-dried to obtain a protein product (the protein having a chol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com