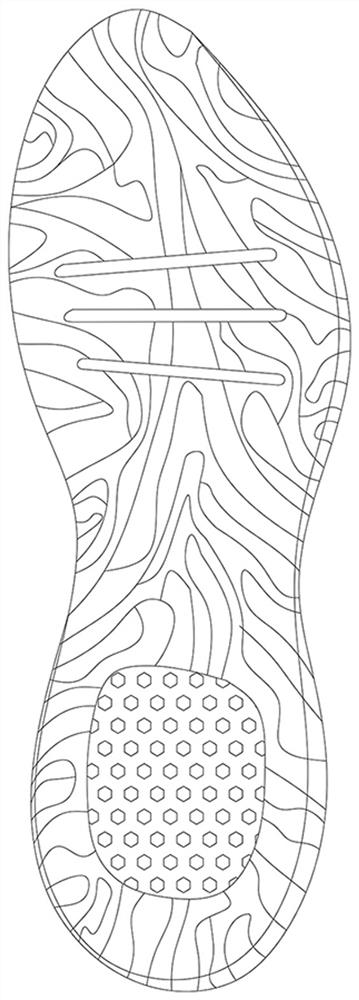

Thermoplastic polyurethane foaming shoe sole with injection stripes and preparation process of thermoplastic polyurethane foaming shoe sole

A thermoplastic polyurethane and thermoplastic polyurethane technology is applied in the field of thermoplastic polyurethane foamed shoe soles and their preparation technology, and achieves the effects of being soft to the touch, not easily damaged, and not easily deformed and hardened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

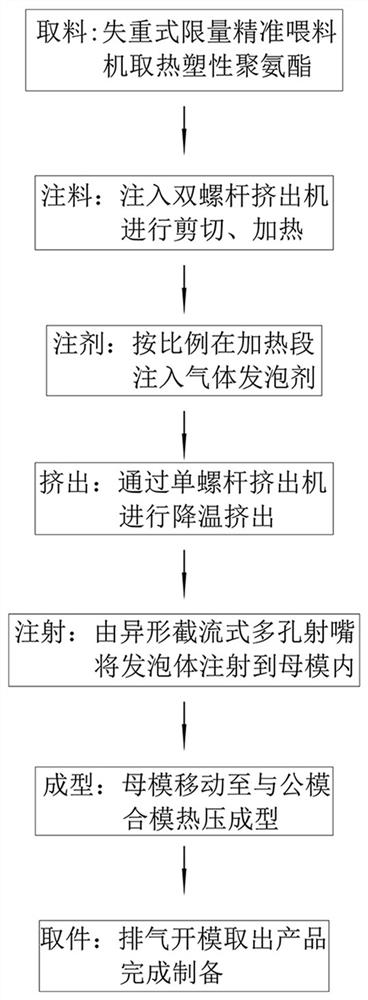

[0041] A kind of preparation technology of the thermoplastic polyurethane foaming shoe sole of band injection stripe line, comprises the following steps:

[0042] S1: According to the content of gas foaming agent in thermoplastic polyurethane, the ratio of gas foaming agent to thermoplastic polyurethane is 1:40, and the thermoplastic polyurethane raw material is put into twin-screw extrusion through a weightless limited precision feeder Machine shearing, combined with a single-screw heating device for heat treatment to form thermoplastic polyurethane in a molten state;

[0043] S2: During the heat treatment, the gas foaming agent is injected according to the proportion of step S1 at the same time, and the gas foaming agent is injected into the extruder barrel to reach a pressure value of 8kpa. Under the condition that the molten thermoplastic polyurethane is continuously sheared and mixed by the twin-screw extruder, it is uniformly formed Mixture of polymer ~ gas homogeneous s...

Embodiment 2

[0050] A kind of preparation technology of the thermoplastic polyurethane foaming shoe sole of band injection stripe line, comprises the following steps:

[0051] S1: According to the content of gas foaming agent in thermoplastic polyurethane, the ratio of gas foaming agent to thermoplastic polyurethane is 1:200, and the thermoplastic polyurethane raw material is put into twin-screw extrusion through a weightless limited precision feeder Machine shearing, combined with a single-screw heating device for heat treatment to form thermoplastic polyurethane in a molten state;

[0052] S2: During the heat treatment, the gas foaming agent is injected according to the ratio of step S1 at the same time, and the gas foaming agent is injected into the extruder barrel to reach a pressure value of 4kpa, and the molten thermoplastic polyurethane is continuously sheared and mixed with the twin-screw extruder to form a uniform Mixture of polymer ~ gas homogeneous system;

[0053] S3: Continue...

Embodiment 3

[0059] A kind of preparation technology of the thermoplastic polyurethane foaming shoe sole of band injection stripe line, comprises the following steps:

[0060] S1: According to the content of gas foaming agent in thermoplastic polyurethane, the ratio of gas foaming agent to thermoplastic polyurethane is 1:25, and the thermoplastic polyurethane raw material is put into twin-screw extrusion through a weightless limited precision feeder Machine shearing, combined with a single-screw heating device for heat treatment to form thermoplastic polyurethane in a molten state;

[0061] S2: During the heat treatment, the gas foaming agent is injected according to the proportion of step S1 at the same time, and the gas foaming agent is injected into the extruder barrel to reach a pressure value of 6kpa, and the molten thermoplastic polyurethane is continuously sheared and mixed with the twin-screw extruder to form a uniform Mixture of polymer ~ gas homogeneous system;

[0062] S3: Cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com