Fiber-doped reinforced microporous concrete product and production method thereof

A concrete product, fiber reinforced technology, applied in ceramic products, manufacturing tools, other household appliances, etc., can solve the problems of easy delamination and shedding, low bonding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

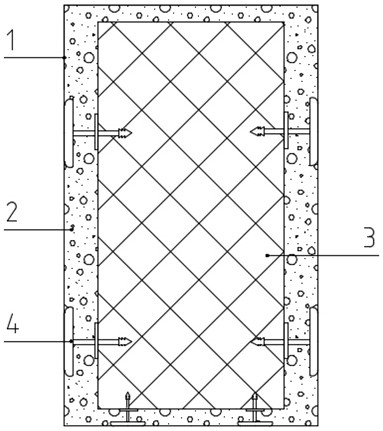

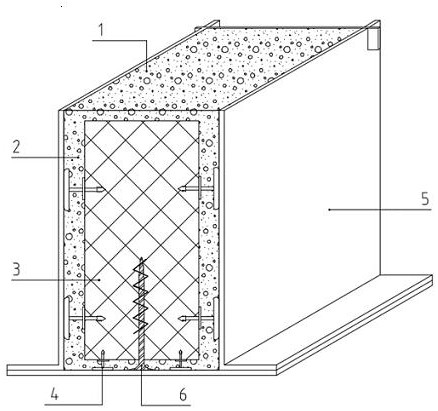

[0016] Such as Figure 1 - Figure 2 As shown, a doped fiber reinforced microporous concrete product 1 is a surface of the surface of the plastic positioning member 4 six-sided heat-insulating core box type structure, by pouring doped fiber reinforced microporous concrete 2 slurry in molding mold 5 The overall no gap is complicated.

[0017] Before pouring doped fibers reinforced microporous concrete 2 slurry, it is necessary to release the molding agent to better demolding; the surface of the plastic positioning member 4 is embedded in the molding die 5 inserted the surface of the plastic positioning member 4. Inside, and the heat preservation core 3 is inserted on the positioning steel bar stab 6 on the bottom plate of the molded mold 5 to prevent the heat-insulating core 3 from being floating during pouring; preparing a doped fiber reinforced microporous concrete 2 slurry according to the ratio: Aluminum silicon-based low shrinkage gelling materials, light collectors, different e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com