Cobalt thiocyanate hydrogen bond type ferroelectric material, and preparation method and application thereof

A technology of thiocyanate cobalt hydrogen and ferroelectric materials, applied in organic chemistry methods, organic chemistry and other directions, can solve the problems of containing toxic metals, expensive preparation process, high energy consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

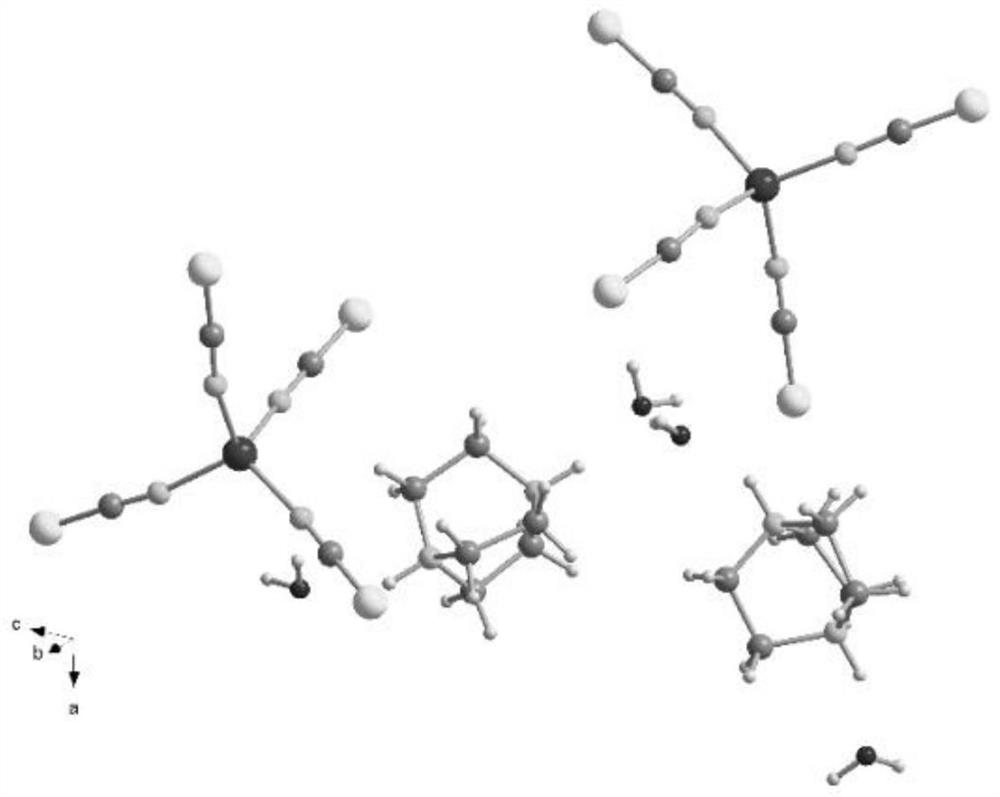

[0038] (1) Add 0.04g dabco to 3.08g methanol to fully dissolve, then add dropwise 0.150mL (5 drops) of hydrochloric acid with a mass concentration of 36.5% (for protonating dabco) and stir well to obtain solvent 1; Cobalt chloride was added into 4.0g water to fully dissolve to obtain solvent 2; 0.24g potassium thiocyanate was added to 5.0g water to fully dissolve to obtain solvent 3;

[0039] (2) After mixing solvent 2 and solvent 3, add in solvent 1, obtain mixed solvent after fully mixing, the molar ratio of cobalt chloride, potassium rhodanide, dabco in this mixed solvent is 1:6:1; The beaker containing the above mixed solvent was placed on a magnetic stirrer and stirred for a certain period of time. Finally, the beaker was sealed with paper towels and rubber bands to prevent impurities from entering the beaker and affecting the normal growth of crystals. After 7 days in a clean environment, the precipitated The dark blue blocky crystals are cobalt thiocyanate hydrogen-bond...

Embodiment 2

[0041] (1) Add 0.03g dabco to 5.385g methanol to fully dissolve, then add dropwise 0.108mL of hydrochloric acid with a mass concentration of 37% (for protonating dabco) and stir fully to obtain solvent 1; add 0.069g cobalt chloride to Fully dissolved in 5.350g water to obtain solvent 2; 0.204g potassium thiocyanate was added to 5.563g water to fully dissolve to obtain solvent 3;

[0042](2) After mixing solvent 2 and solvent 3, add in solvent 1, obtain mixed solvent after fully mixing, the molar ratio of cobalt chloride, potassium thiocyanate, dabco in this mixed solvent is 1:5:2; The beaker containing the above mixed solvent was placed on a magnetic stirrer for a certain period of time, and finally the beaker was sealed with paper towels and rubber bands to prevent impurities from entering the beaker and affecting the normal growth of crystals. After 6 days in a clean environment, the precipitated The dark blue blocky crystals are cobalt thiocyanate hydrogen-bonding ferroelec...

Embodiment 3

[0044] (1) Add 0.07g dabco to 2.308g methanol to fully dissolve, then add dropwise 0.350mL of hydrochloric acid with a mass concentration of 36% (for protonating dabco) and stir fully to obtain solvent 1; add 0.107g cobalt chloride to Fully dissolve in 3.450g water to obtain solvent 2; add 0.267g potassium thiocyanate to 4.250g water and fully dissolve to obtain solvent 3;

[0045] (2) After mixing solvent 2 and solvent 3, add in solvent 1, obtain mixed solvent after fully mixing, the molar ratio of cobalt chloride, potassium rhodanide, dabco in this mixed solvent is 2:5:2; The beaker containing the above mixed solvent was placed on a magnetic stirrer for a certain period of time, and finally the beaker was sealed with paper towels and rubber bands to prevent impurities from entering the beaker and affecting the normal growth of crystals. After 8 days in a clean environment, the precipitated The dark blue blocky crystals are cobalt thiocyanate hydrogen-bonding ferroelectric ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com