Segmented construction method for gravity retaining wall

A construction method and retaining wall technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of high construction joint construction requirements, decreased overall strength of retaining walls, difficulty in one-time forming and high risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

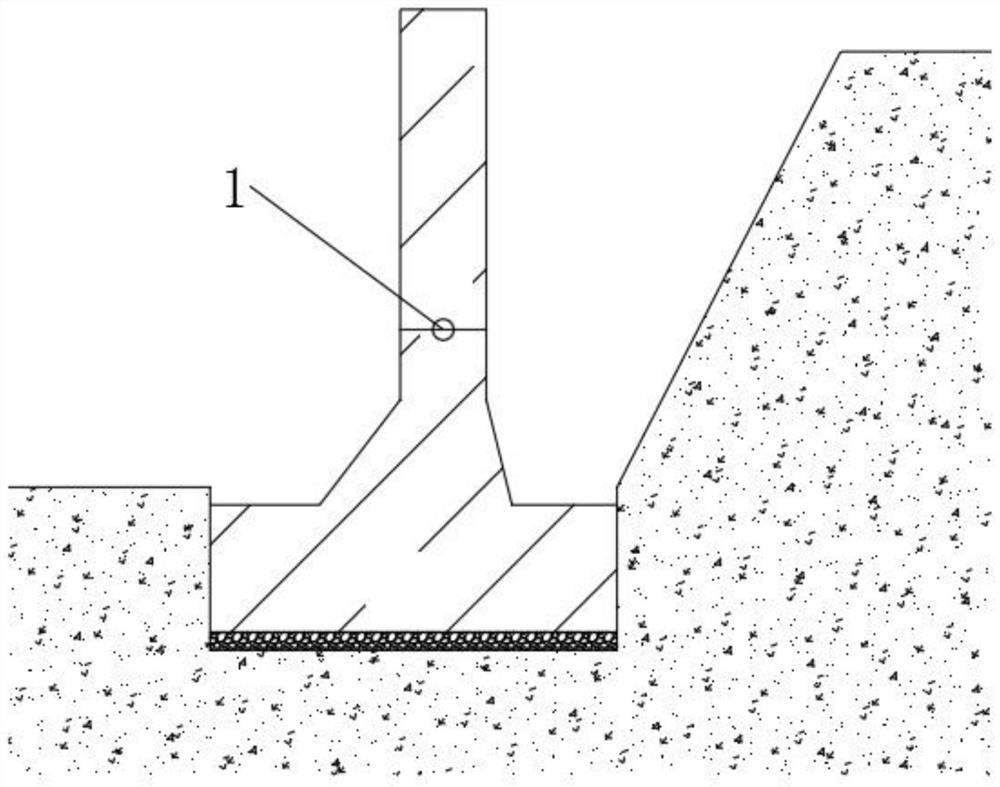

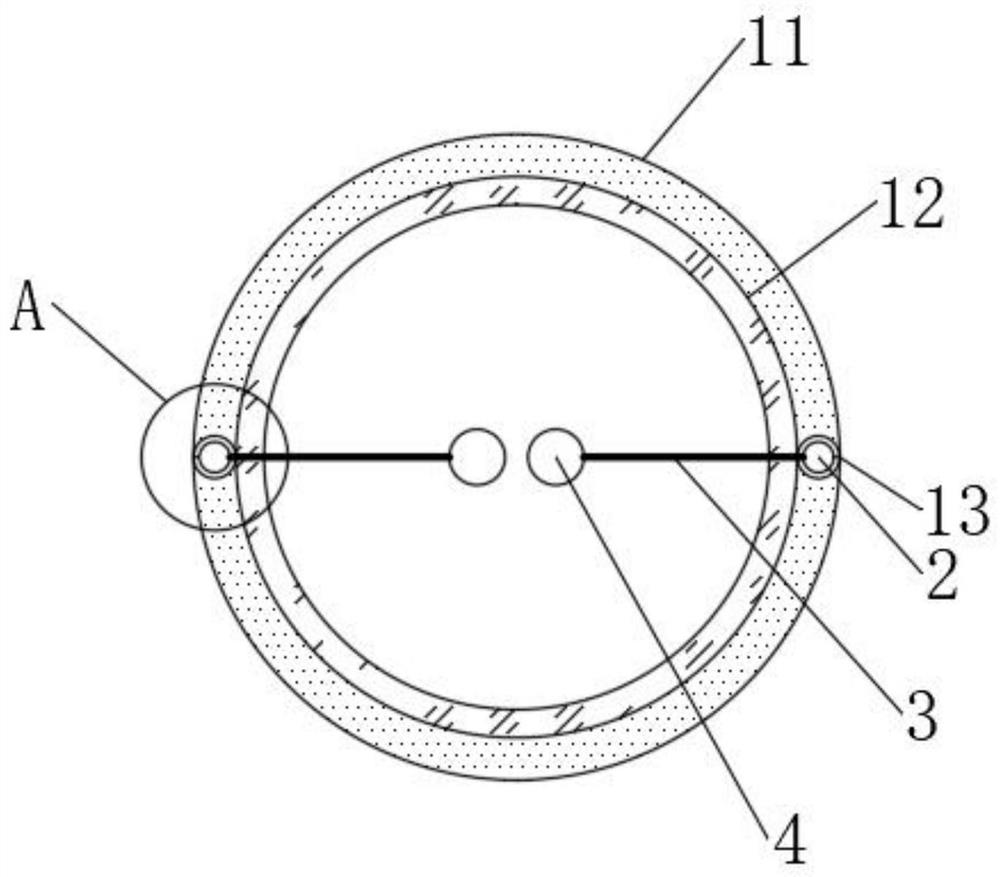

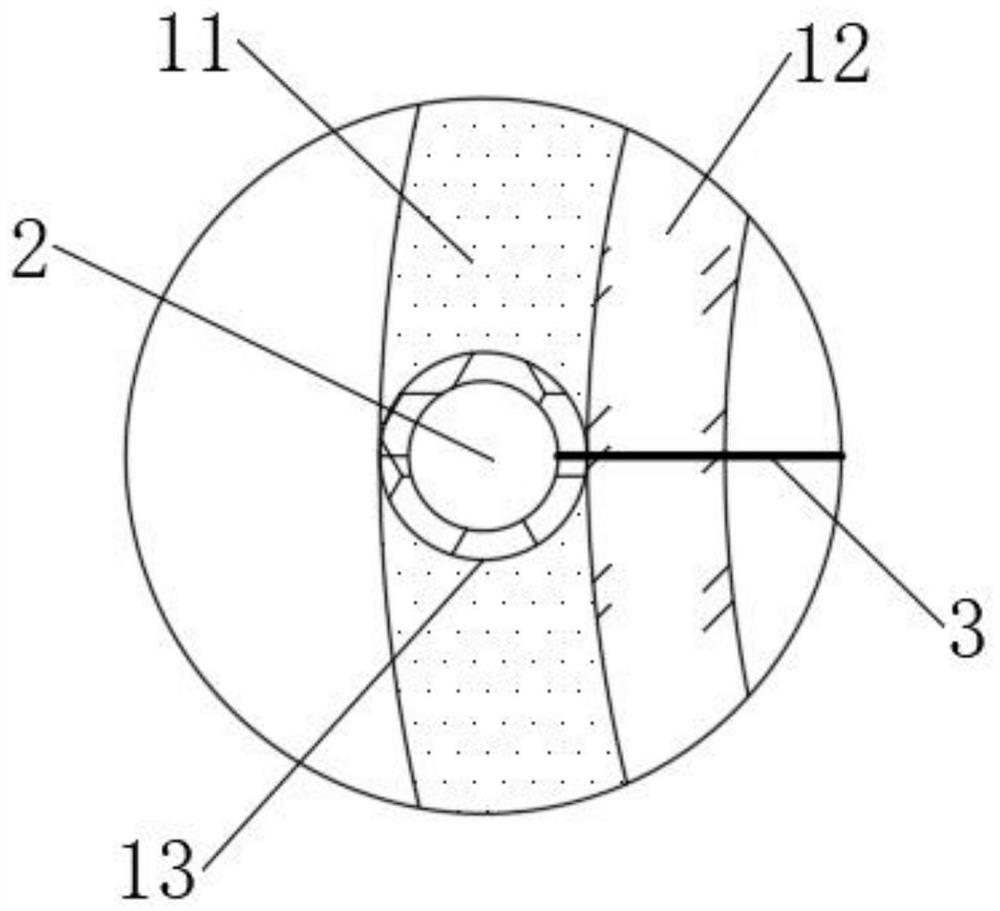

[0045] see figure 1 , a segmented construction method for a gravity retaining wall, comprising the following steps:

[0046] S1. Excavate the foundation pit, then clean up the garbage and sundries in the foundation pit, level and compact it, and then lay a 5cm gravel cushion;

[0047] S2. Set out line measurement to determine the coordinate points of the cap, including the plane coordinates and elevation of the corner points, and then erect the formwork and bind the steel bars, wherein the height of the formwork is 2cm higher than the height of the cap;

[0048] S3. Pour concrete into the formwork and vibrate evenly, and reserve a plurality of evenly distributed anti-seepage balls 1 at the construction joints. After 3 days, remove the formwork to cover the geotextile and sprinkle water for maintenance until the strength reaches 80% of the design value;

[0049] S4. Carry out chiseling treatment at the construction joints at the upper end of the cap, and clean up the debris, e...

Embodiment 2

[0062] A segmented construction method for a gravity retaining wall, comprising the following steps:

[0063] S1. Excavate the foundation pit, then clean up the garbage and sundries in the foundation pit, level and compact it, and then lay an 8cm gravel cushion;

[0064] S2. Set out the line measurement to determine the coordinate points of the cap, including the plane coordinates and elevation of the corner points, and then erect the formwork and bind the steel bars, wherein the height of the formwork is 2.5cm higher than the height of the cap;

[0065] S3. Pour concrete into the formwork and vibrate evenly, and reserve a plurality of evenly distributed anti-seepage balls 1 at the construction joints. After 5 days, remove the formwork to cover the geotextile and sprinkle water for maintenance until the strength reaches 80% of the design value;

[0066] S4. Carry out chiseling treatment at the construction joints at the upper end of the cap, and clean up the debris, erect the ...

Embodiment 3

[0074] A segmented construction method for a gravity retaining wall, comprising the following steps:

[0075] S1. Excavate the foundation pit, then clean up the garbage and sundries in the foundation pit, level and compact it, and then lay a 10cm gravel cushion;

[0076] S2. Set out line measurement to determine the coordinate points of the cap, including the plane coordinates and elevation of the corner points, and then erect the formwork and bind the steel bars, wherein the height of the formwork is 3cm higher than the height of the cap;

[0077] S3. Pour concrete into the formwork and vibrate evenly, and reserve a plurality of evenly distributed anti-seepage balls 1 at the construction joints. After 7 days, remove the formwork to cover the geotextile and sprinkle water for maintenance until the strength reaches 80% of the design value;

[0078] S4. Carry out roughing treatment at the construction joints at the upper end of the cap, and clean up the debris, erect the wall fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com