Building curtain wall steel structure rust removal method

A steel structure and curtain wall technology, applied in the direction of building structure, construction, etc., can solve problems such as cracking and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

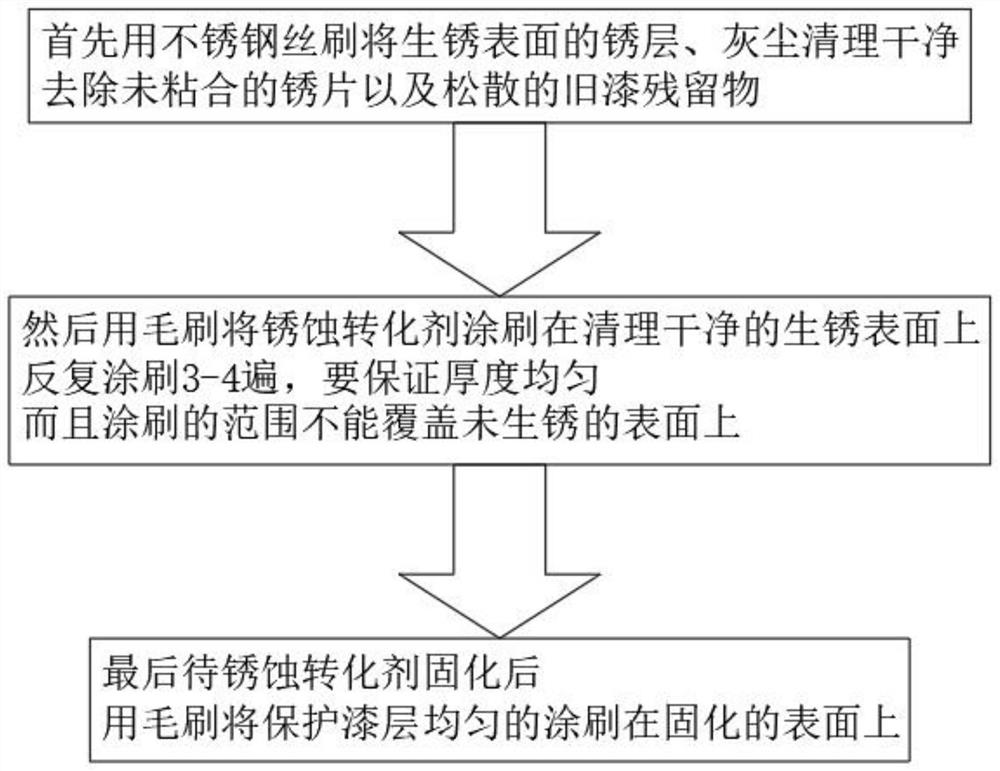

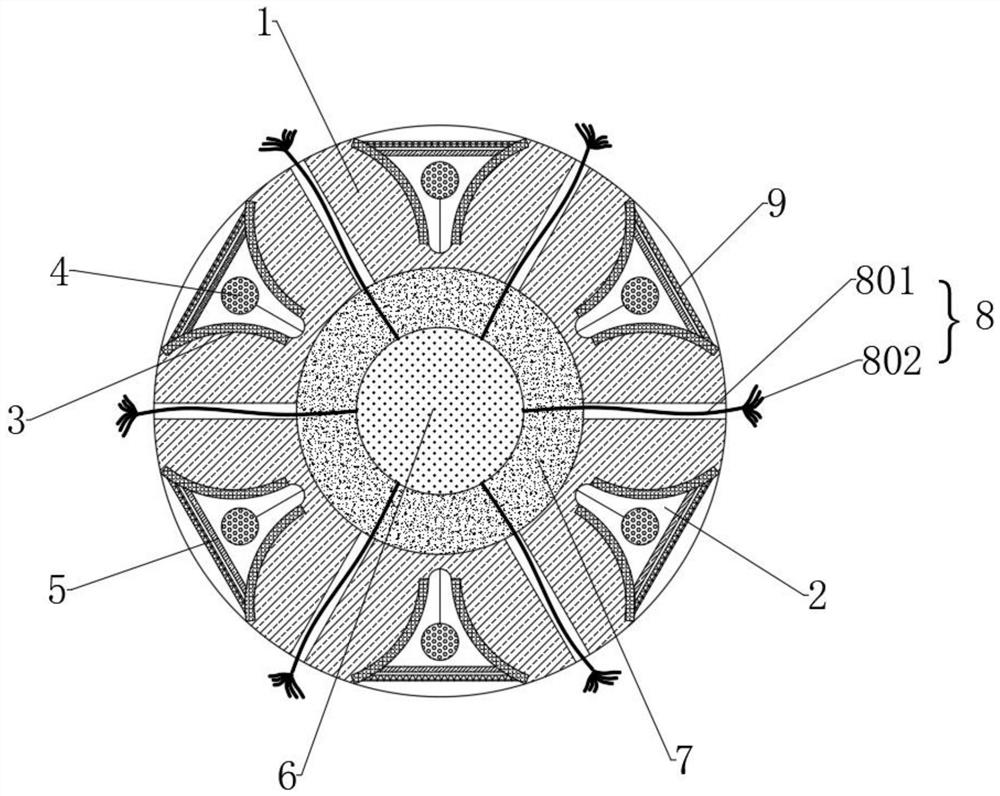

[0047] see Figure 1-5 , a method for derusting building curtain wall steel structures, please refer to Figure 1-2 , including the following steps:

[0048] S1, first use a stainless steel wire brush to clean the rust layer and dust on the rusty surface, and remove unbonded rust flakes and loose old paint residues;

[0049] S2, then use a brush to brush the rust conversion agent on the cleaned rusty surface, and repeatedly brush it 3-4 times to ensure that the thickness is uniform, and the scope of the brushing cannot cover the non-rusted surface (rust conversion The agent can choose MT120 model, and can also be selected according to actual needs);

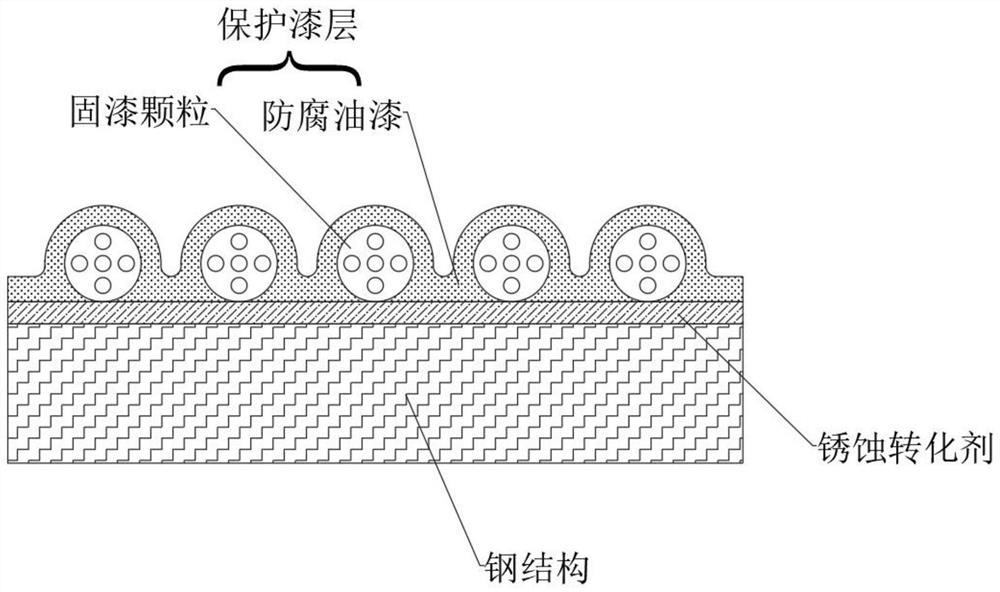

[0050] S3. Finally, after the rust conversion agent is cured, use a brush to evenly paint the protective paint layer on the cured surface.

[0051] The brushing method of protective paint layer in the described S3 step is:

[0052] S31, first pour the solid paint particles into the anti-corrosion paint in proportion, and full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com