Method for determining size of bubbles in system for preparing TA through PX oxidation

A technology of bubbles and oxygen, applied in the direction of instruments, surface/boundary effects, measuring devices, etc., can solve the problems of easy decarboxylation of system substances, solvent combustion, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

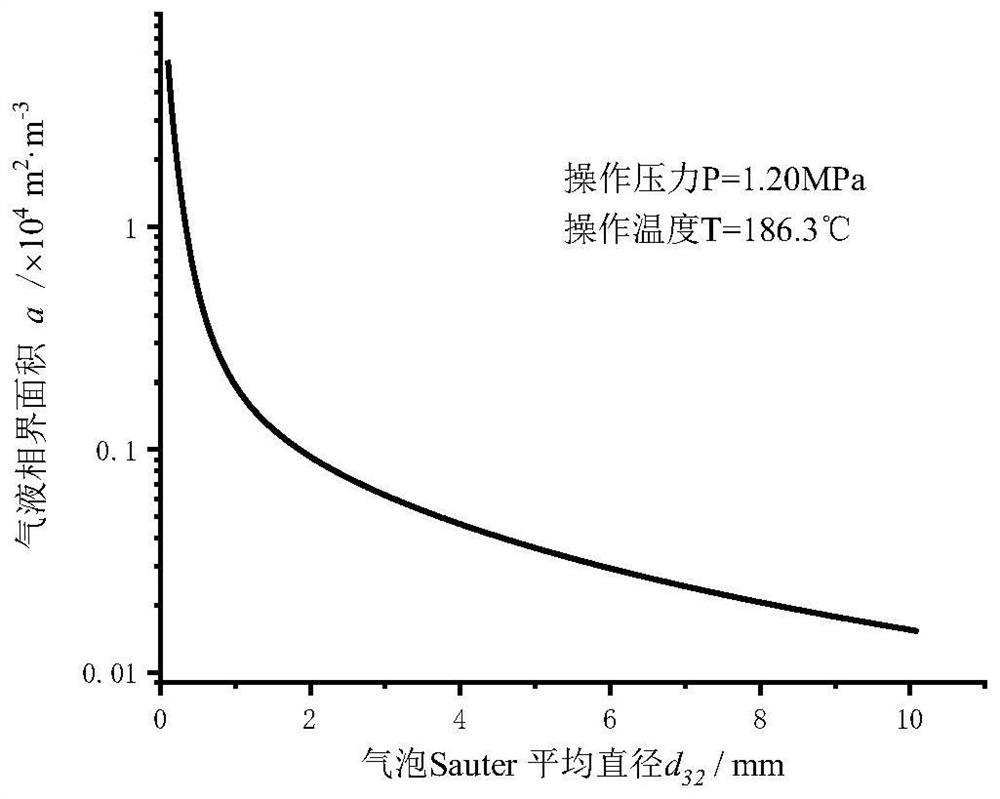

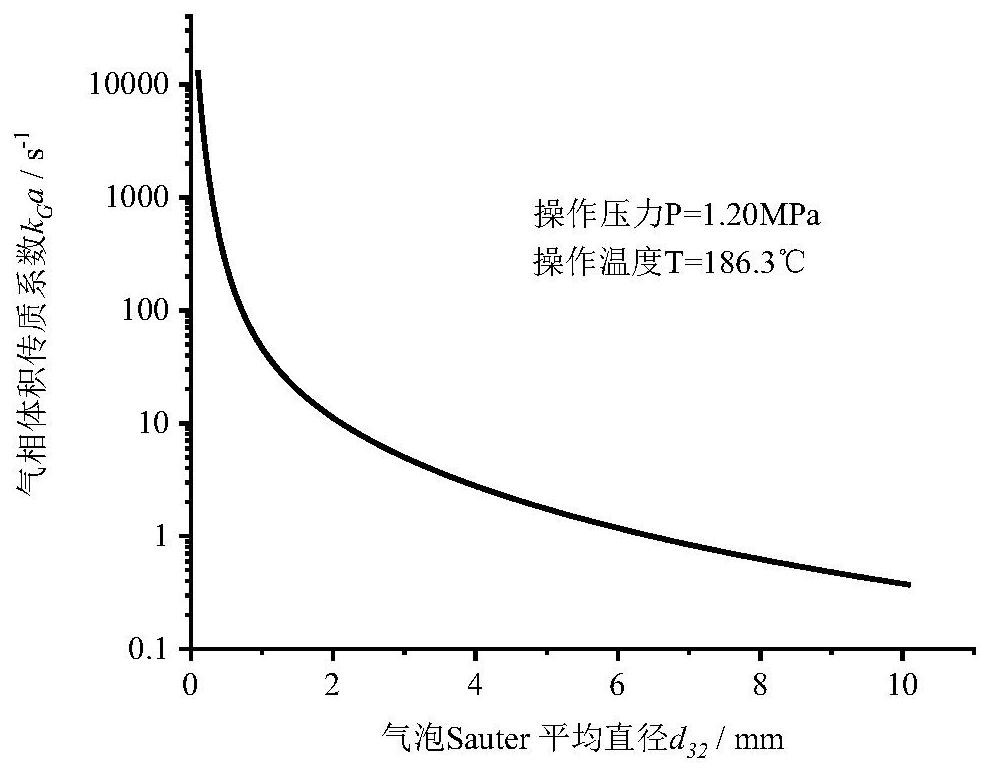

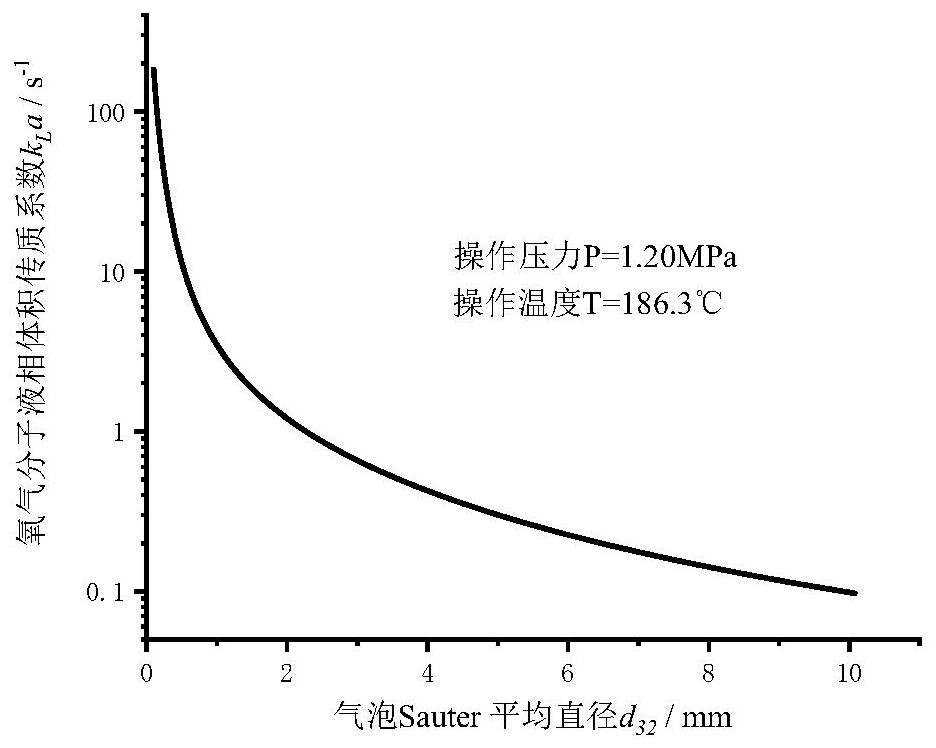

[0084] This embodiment is based on the modeling method of the present invention, aiming at the continuous bubbling reactor and the existing operating conditions of the PX liquid-phase oxidation of TA in a certain enterprise, the effect of the size of the bubbles in the reactor on the micro-interface unit under pure aerodynamic conditions is studied. Effects on macroscopic reaction rates. The size of the bubbles in the reactor is affected by the reactor structure, physical parameters, and operating conditions, and its regulation model under purely pneumatic operating conditions can refer to the applicant's prior patent CN109684769A.

[0085] The calculation conditions are as follows:

[0086] Reactor Design Parameters:

[0087] Reactor height H 0 =4.8m; reactor cross-sectional area S 0 =0.9499m 2 ;

[0088] Liquid density ρ L =807kg / m 3 ; The molar mass of the liquid phase M 1 =0.049kg / mol;

[0089] Operating pressure P m =1.2MPa;

[0090] PX flow Q L =3.2×10 -3 m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com