Method for rapidly extracting and analyzing micro-plastics in soil based on density separation method

A technology of density separation and microplastics, which is applied in the analysis of materials, material analysis by optical means, preparation of samples for testing, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1. Detection of microplastics in Hangzhou farmland

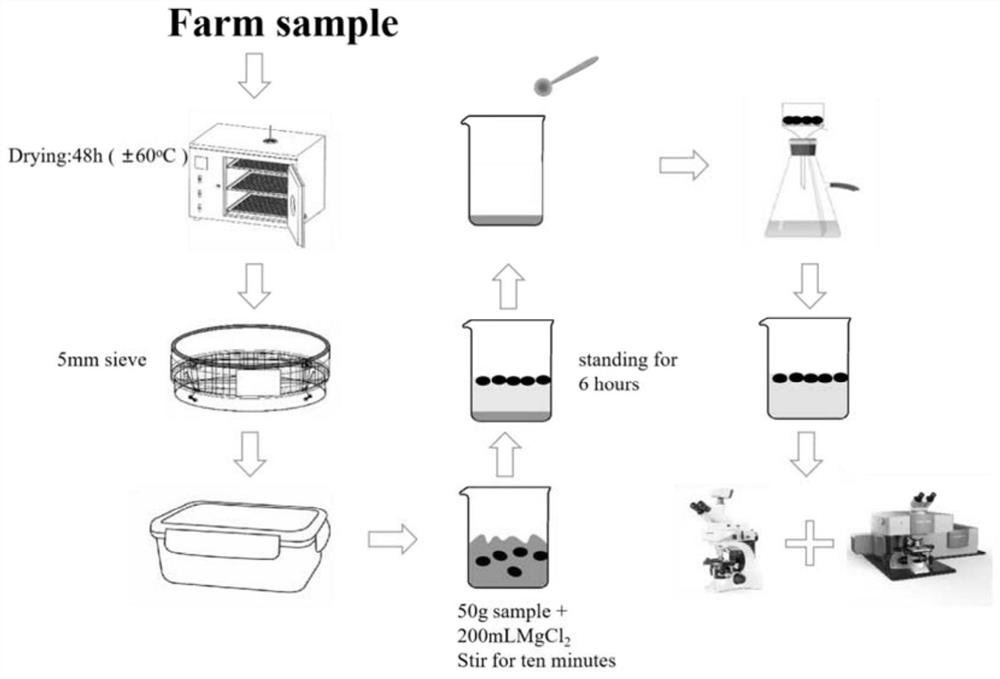

[0025] Refer to as figure 1 The flow chart shown is the rapid extraction and detection of microplastics in soil.

[0026] S1. Extraction of microplastics in soil:

[0027] Take 50g of the soil to be tested, dry it in an oven (drying temperature 60°C, drying time 48 hours), sieve out particles with a particle size above 5mm, and then add it to MgCl 2 In a saturated aqueous solution, the volume-to-mass ratio of the extract to the soil to be tested is 200ml:50g. After fully stirring for ten minutes, the microplastics float in the solution. After standing for 6 hours, the suspension and the soil are completely layered; then the suspension is poured out. , carry out suction filtration, place the filtered microplastics in 30% hydrogen peroxide at 60° C. for 48 hours until the solution is clear, and then dry.

[0028] S2. Analysis of microplastics in soil:

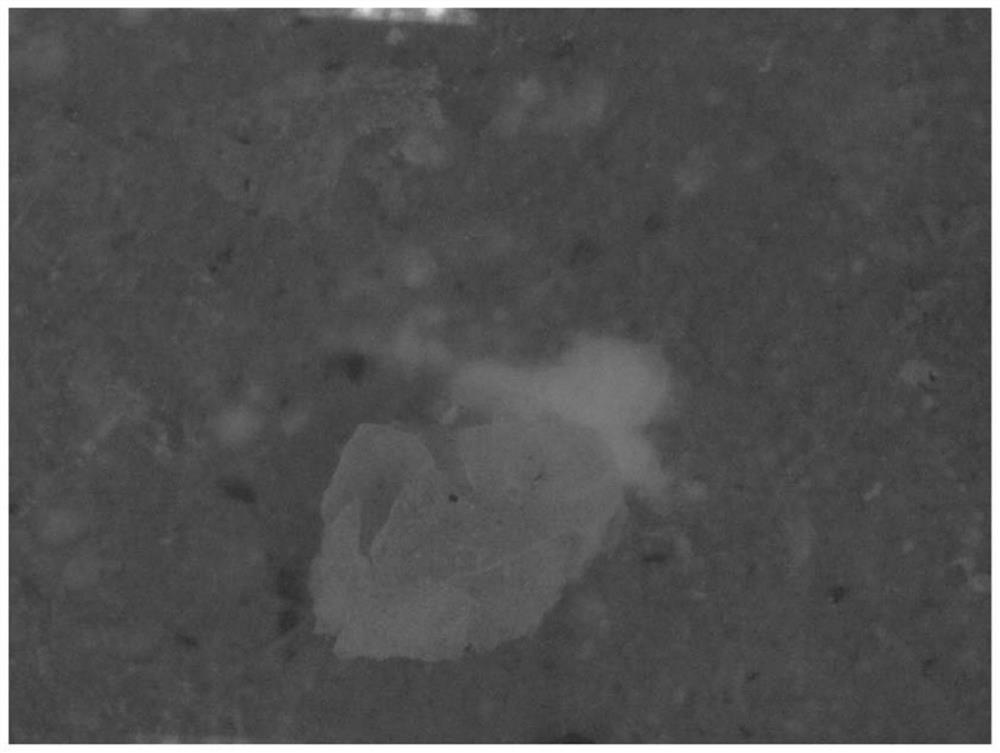

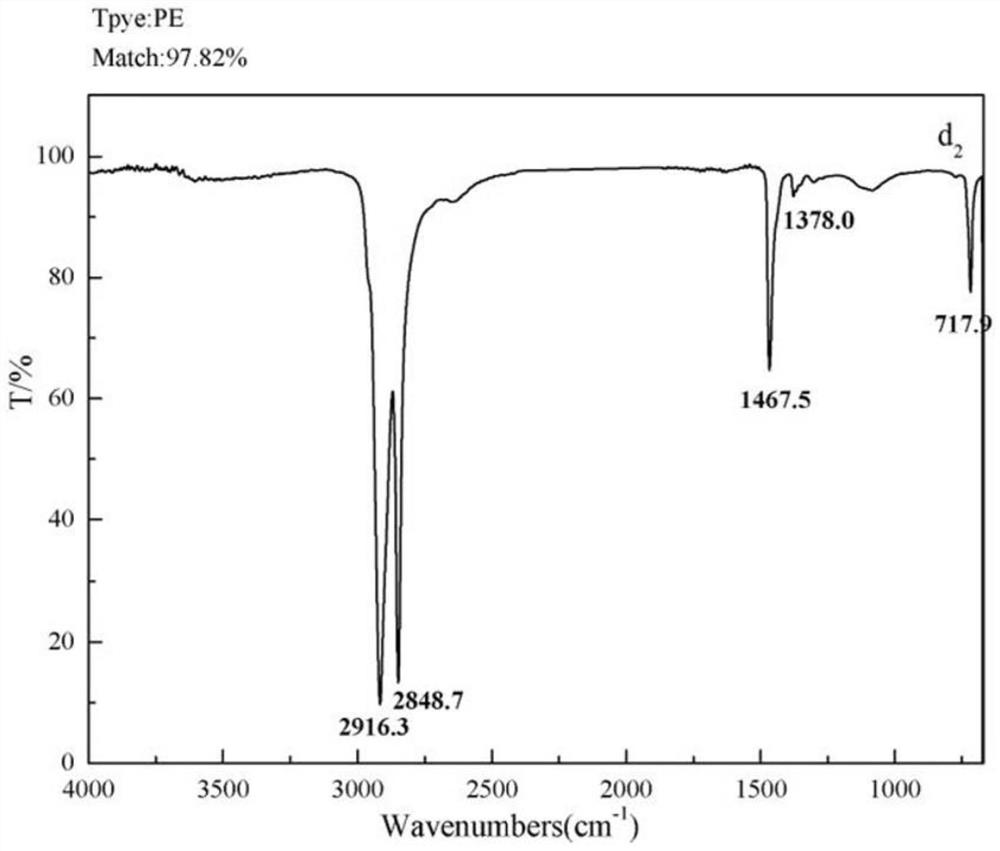

[0029] The dried microplastics were observed under a mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com