Immersed liquid cooling system

An immersion and water cooling system technology, applied in the field of server heat dissipation, can solve the problems of difficult air cooling, direct contact liquid cooling economic benefits and unsatisfactory heat dissipation performance, and high heating power of motherboard chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

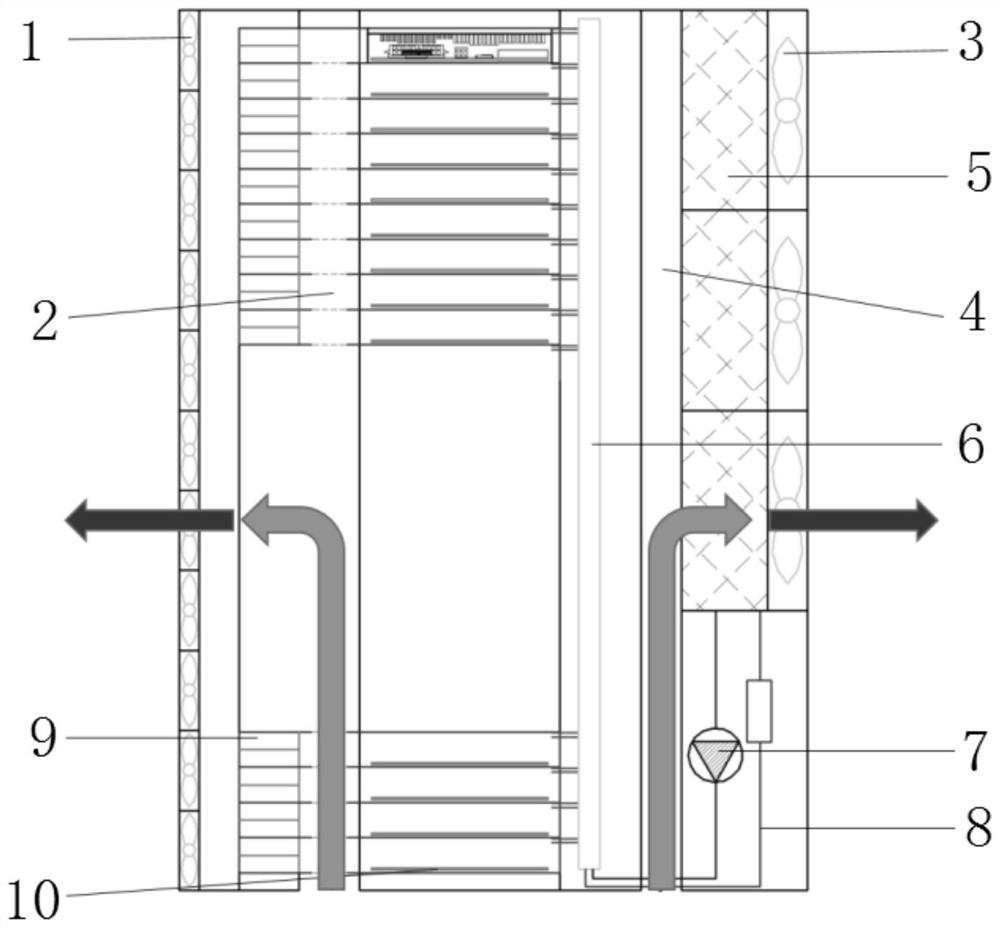

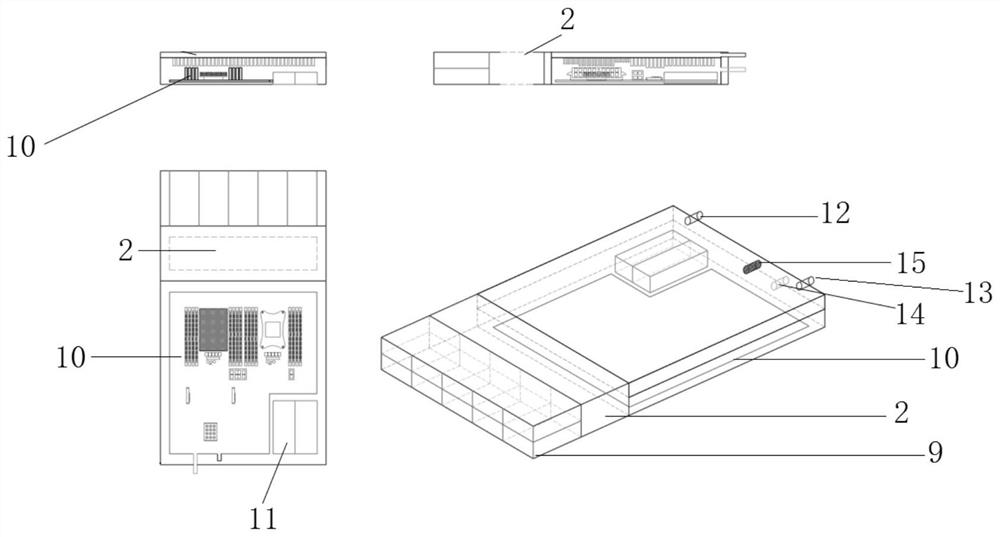

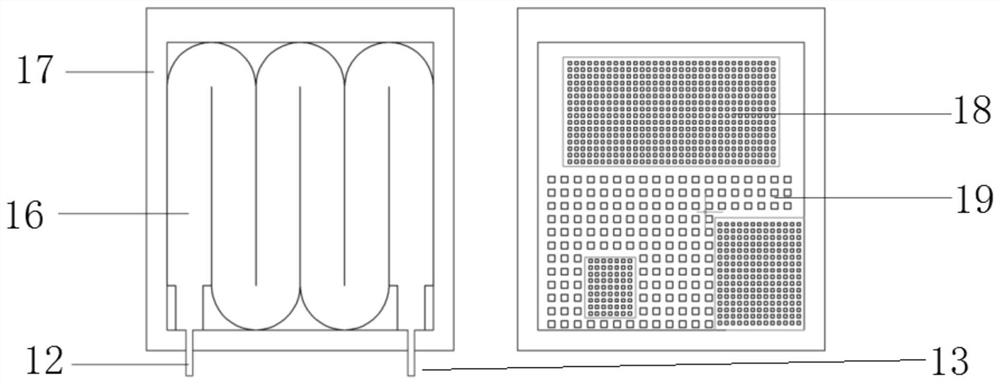

[0048] The present invention provides an immersion liquid cooling system, please refer to Figure 1 to Figure 3 ,include:

[0049] Liquid-cooled server cabinets, liquid-cooled servers, auxiliary cooling systems and water-cooling systems.

[0050] The liquid-cooled server cabinet is equipped with a liquid-cooled server, an auxiliary cooling system and a water-cooling system.

[0051] The front end of the liquid-cooled server cabinet is provided with a first fan 1 and a first cooling air duct 2, and the rear end of the liquid-cooled server cabinet is provided with a second fan 3, a second cooling air duct 4, a dry cooler 5, a water collector 6, Cooling water pump 7, cooling system pipeline 8, hard disk 9, main board 10, server power supply 11, plate cover flow channel inlet 12, plate cover flow channel outlet 13, liquid cooling box replenishment port 14, liquid cooling box pressure regulator 15, board Cover flow channel 16, liquid cooling heat dissipation plate 17, high power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com