Preparation method of carbon aerogel containing double metal sites and application of aluminum-air battery

A carbon aerogel, battery application technology, used in battery electrodes, fuel cell-type half-cells and primary battery-type half-cells, circuits, etc., can solve problems such as slow kinetics and low ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

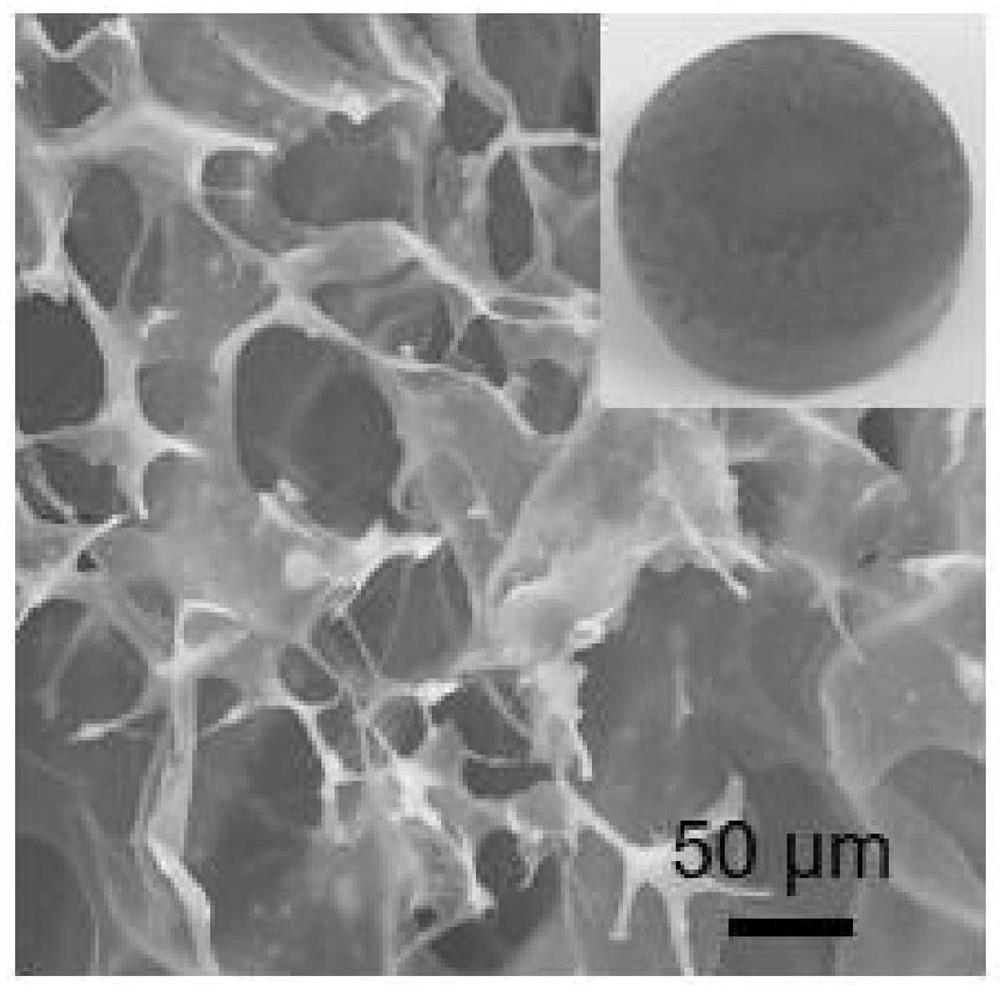

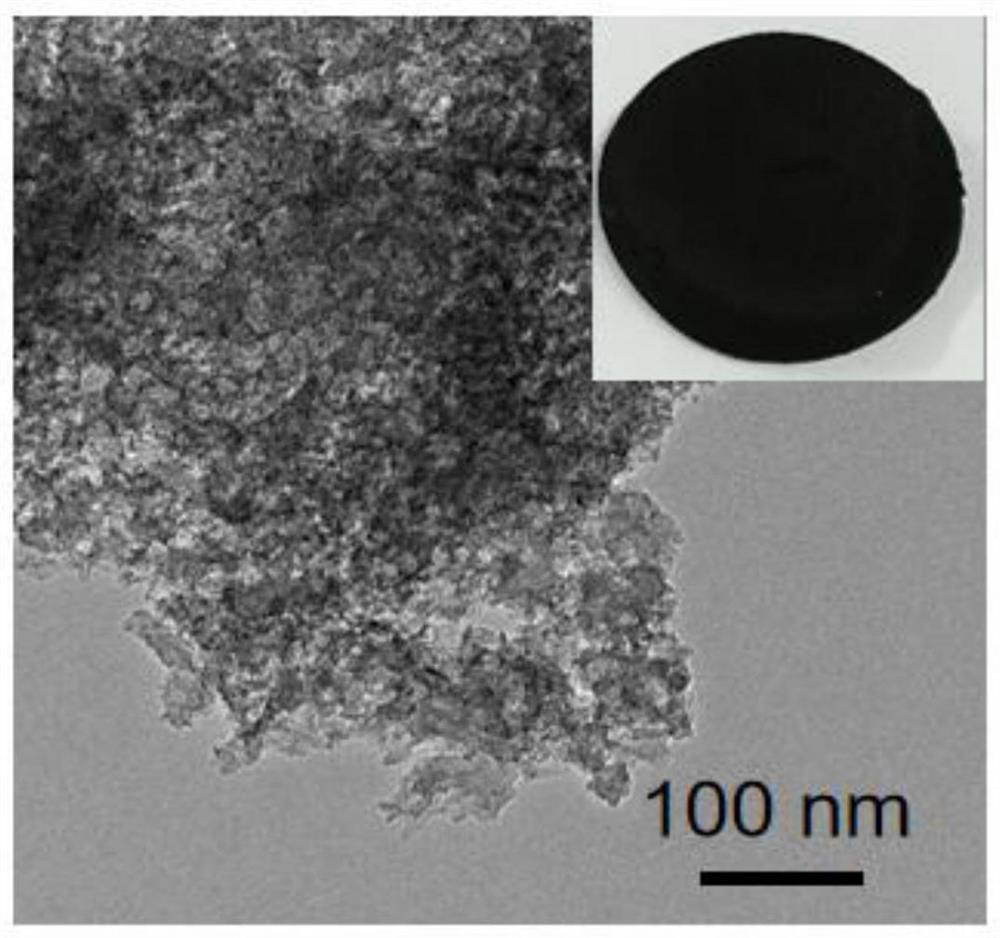

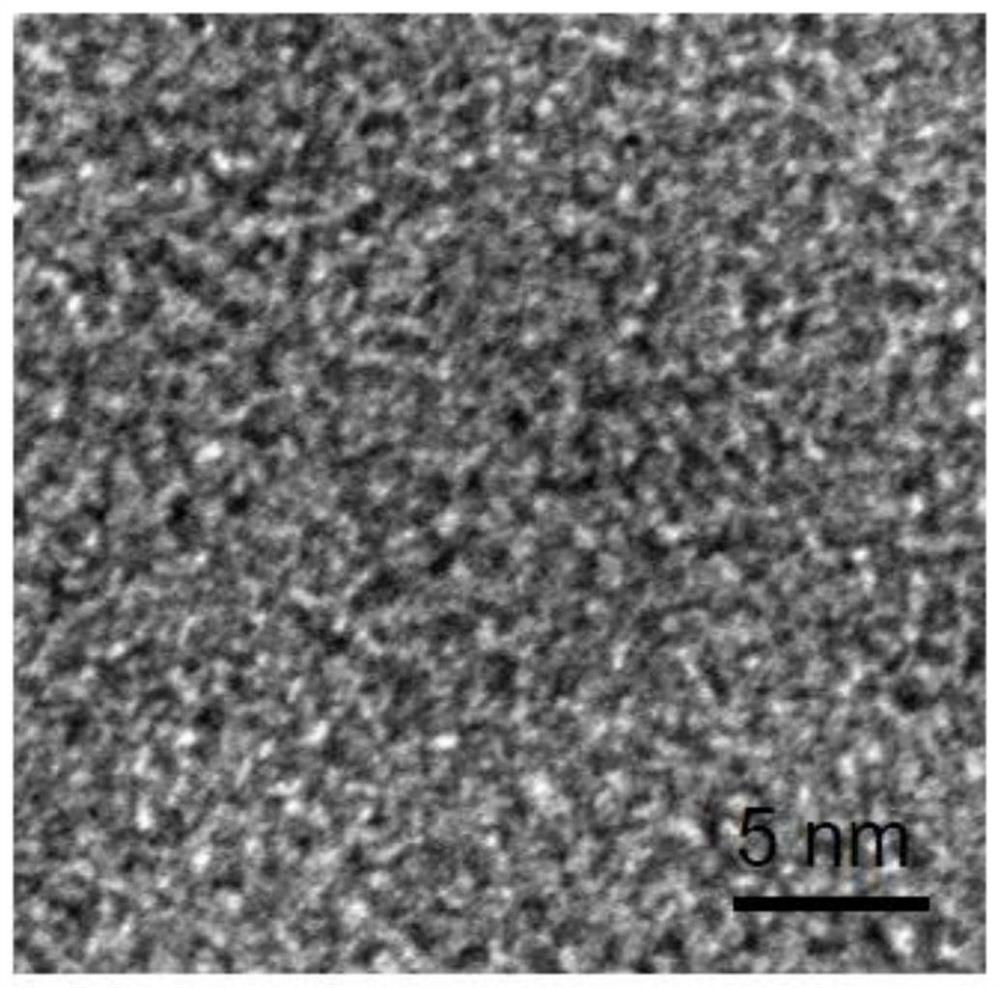

[0039] The embodiment of the present invention designs a method for preparing carbon aerogels containing bimetallic sites, and its specific technical scheme is as follows:

[0040]Synthesis of S100 gelatin hydrogel: 60 mg of gelatin with a freezing capacity of 250 bloom, 30 mg of silica nanoparticles with a particle size of 15 nm and 2.51 mL of deionized water were placed in a 20 mL small glass bottle, stirred at room temperature for 40-60 min, and then Stir in a water bath at 60°C for 10-20min, return to room temperature after it is completely dissolved, add 150μL of iron-phenanthroline complex at a concentration of 0.2mol / L, 100μL of copper-o-phenanthroline complex at a concentration of 0.2mol / L Nitrophenanthrene complex, 80 μL, zinc acetate solution with a concentration of 1mol / L were mixed evenly, and the obtained solution was frozen in a -4°C refrigerator for 20 minutes to form a hydrogel, which was named G / Fe(PM) 3 -Cu(PM) 3 ;

[0041] Preparation of S200 iron-copper d...

Embodiment 2

[0048] A method for preparing a bimetallic site carbon airgel catalyst provided in the embodiment of the present invention, the specific steps are as follows:

[0049] S100, the synthesis of biomass hydrogel: Weigh 60mg of 250bloom gelatin and 30mg of silica nanoparticles (15nm) in a small glass bottle, add 2.51mL of deionized water, stir at room temperature for 40min to make it completely absorbed, and then Heated in a water bath at 60°C for 10 minutes, and returned to room temperature after it was completely dissolved, then added 150 μL of 0.2M iron-phenanthroline complex, 100 μL of 0.2M copper-phenanthroline complex, and 80 μL of 1M The zinc acetate solution was mixed evenly, and the obtained solution was placed in a -4°C refrigerator for 20 minutes to form a hydrogel, which was named G / Fe(PM) 3 -Cu(PM) 3 .

[0050] Preparation of S200 iron-copper double-site carbon airgel: G / Fe(PM) synthesized in step S100 3 -Cu(PM) 3 After the hydrogel was freeze-dried overnight, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com