Pelletization formula and processing method of brassica campestris seeds

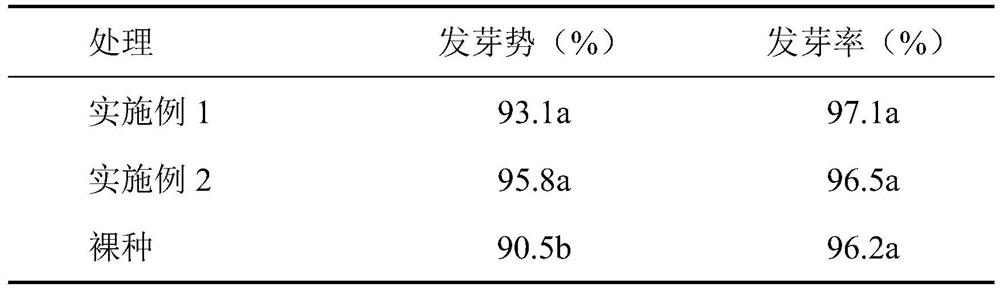

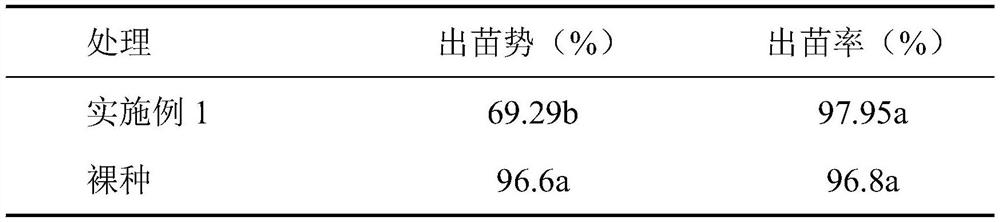

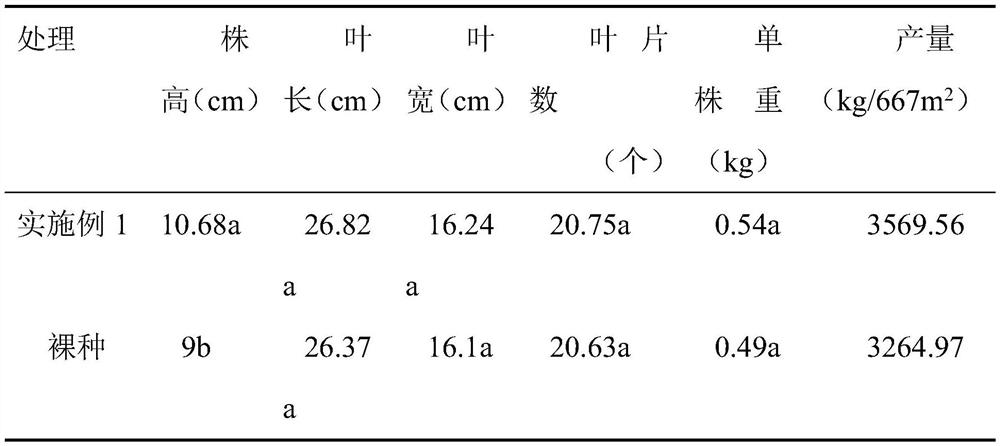

A processing method and a technology for black tamales are applied in the field of seed pelleting formulation and processing of black tamales, which can solve problems such as less research, and achieve the effects of high germination rate, tidy germination, and improved growth index and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) select the Heidi cabbage seeds to be pelletized;

[0022] (2) talcum powder is pulverized to 800 orders;

[0023] (3) Dissolve 45g of polyvinyl alcohol (4.5%) weighed in 1000ml of water, heat in a water bath at 95 degrees until completely melted, and cool to room temperature. Dissolve the weighed 100mg (100mg / L) matrine and 80mg (80mg / L) Vc in the polyvinyl alcohol solution at room temperature, and stir evenly;

[0024] (4) Weigh powder. Weigh 140g, 150g, 160g, 170g, 180g, 180g, 190g, 200g, 210g, 220g of talc powder respectively; add in 10 times;

[0025] (5) Pour 300g of seeds into a pelletizing machine with a rotational speed of 38Hz, add 37ml of binder after 5s, and add 140g of talcum powder after 10s (10-15s to complete);

[0026] (6) After 20 seconds, add 150 g of talcum powder and 39 ml of adhesive to step (5). Add the next time every 30-50s, and the ratio of binder and talcum powder is 1:3.8 (ml:g) each time;

[0027] (7) The seeds were taken out for the...

Embodiment 2

[0031] (1) select the Heidi cabbage seeds to be pelletized;

[0032] (2) talcum powder is pulverized to 800 orders;

[0033] (3) Dissolve 22.5g of polyvinyl alcohol (4.5%) weighed in 500ml of water, heat in a water bath at 95 degrees until completely melted, and cool to room temperature. Dissolve the weighed 50mg (100mg / L) matrine and 40mg (40mg / L) Vc in the polyvinyl alcohol solution at room temperature, and stir evenly;

[0034] (4) Weigh powder. Weigh 160g, 170g, 180g, 190g, 200g of talcum powder respectively, add in 5 times;

[0035] (5) Pour 300g of seeds into a pelletizing machine with a rotational speed of 38Hz, add 42ml of binder after 5s, and add 160g of talcum powder after 10s (10-15s to complete);

[0036] (6) After 20 seconds, add 170 g of talcum powder and 44 ml of adhesive to step (5). Add the next time every 30-50s, and the ratio of binder and talcum powder is 1:3.8 (ml:g) each time;

[0037] (7) Take out the seeds for the 2nd and 4th times, and dry them un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com