Method for processing canned meat products step by step by using multiple natural preservatives

A technology of natural preservatives and compound preservatives, applied in food ingredients containing natural extracts, preservation of meat/fish with chemicals, food ingredients as antimicrobial preservation, etc., can solve the problem of narrow antibacterial range of natural antiseptic preservatives, The impact of product flavor and quality, improper use of lysozyme and other issues, to achieve the effect of good thermal stability, high safety, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

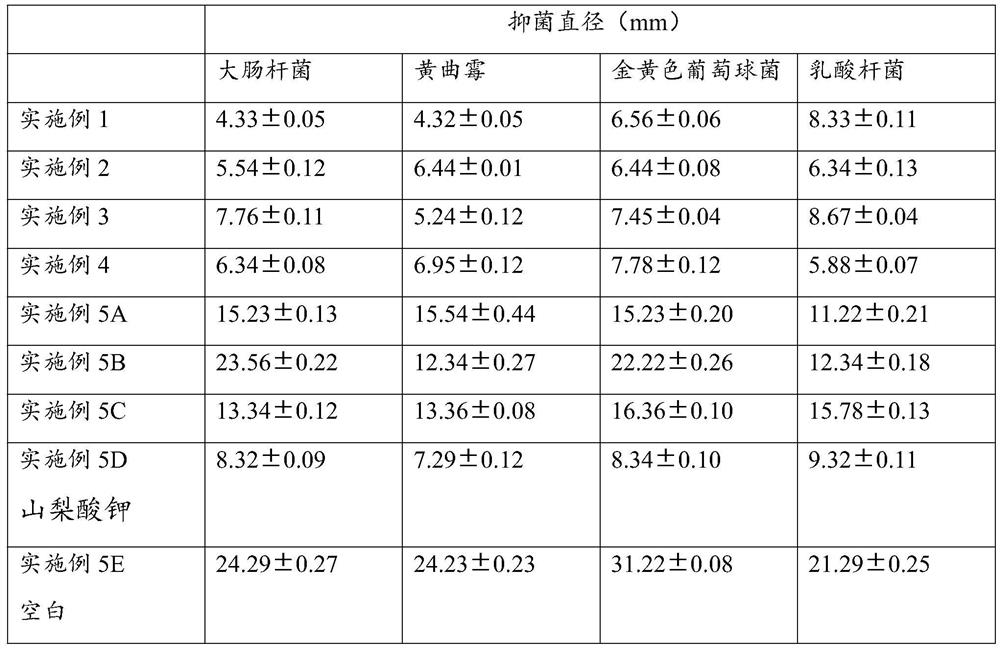

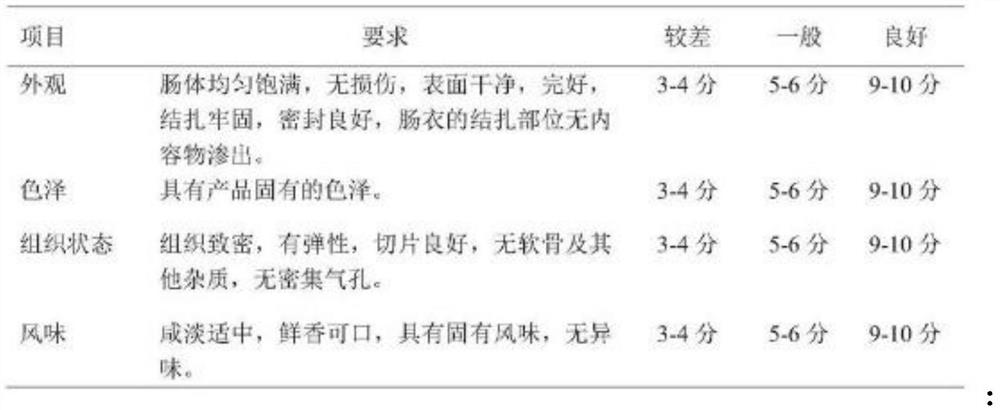

Examples

Embodiment 1

[0038] A method for step-by-step processing of meat filling products using multiple natural preservatives, characterized in that the method comprises the steps of:

[0039] 1) Preparation: Use a dicing machine to cut 65% of the total weight into 1-2cm diced meat for later use, and use an 8mm orifice meat grinder to grind the remaining pork into minced meat for later use after selecting impurities, and prepare cured meat material , and divided into two parts according to the ratio of diced meat and minced meat;

[0040] Add 50 grams of starch, 30 grams of salt, 30 grams of white wine, 10 grams of sugar, and 20 grams of spices per kilogram of meat.

[0041] The addition ratio of the meat, cured meat material and natural preservative is 91:8:1.

[0042] 2) Stirring and pickling of diced meat: put 65% of diced meat and 65% of cured meat material and natural preservatives lysozyme and glycine into a beater, mix and stir and marinate for 2-4 hours;

[0043] 3) Stir and marinate th...

Embodiment 2

[0050] A method for step-by-step processing of meat filling products using multiple natural preservatives, characterized in that the method comprises the steps of:

[0051] 1) Prepare materials: cut 70% of the total weight of meat into 1-2cm diced meat with a dicing machine for later use, and use an 8mm orifice meat grinder to grind the remaining pork into minced meat for later use after selecting impurities;

[0052] Prepare cured meat material and divide it into two parts according to the ratio of diced meat and meat stuffing; add 50 grams of starch, 30 grams of salt, 30 grams of white wine, 10 grams of sugar and 20 grams of spices for each kilogram of meat material.

[0053] The addition ratio of the meat, cured meat material and natural preservative is 95:4:1.

[0054] 2) Stir and marinate the diced meat: put 70% of the diced meat, 70% of the cured meat material, and natural preservatives lysozyme and glycine into a beater, mix and stir, and marinate for 3 hours;

[0055]...

Embodiment 3

[0060] A method for step-by-step processing of meat filling products using multiple natural preservatives, characterized in that the method comprises the steps of:

[0061] 1) Prepare materials: cut 70% of the total weight of meat into 1-2cm diced meat with a dicing machine for later use, and use an 8mm orifice meat grinder to grind the remaining pork into minced meat for later use after selecting impurities;

[0062] Prepare cured meat material and divide it into two parts according to the ratio of diced meat and meat stuffing; add 50 grams of starch, 30 grams of salt, 30 grams of white wine, 10 grams of sugar and 20 grams of spices for each kilogram of meat material.

[0063] The addition ratio of the meat, cured meat material and natural preservative is 92:6:2.

[0064] 2) Stir and marinate the diced meat: put 70% of the diced meat, 70% of the cured meat material, and natural preservatives lysozyme and glycine into a beater, mix and stir, and marinate for 2 hours;

[0065]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com