Cooling sleeve and optical fiber conduit with same

A technology for cooling sleeves and optical fiber conduits, applied in the field of medical devices, can solve the problems affecting the stability and accuracy of laser light output, equipment collision and deformation, and increased manufacturing costs, and achieves good cooling effect, reduced volume, and smooth installation process. slippery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

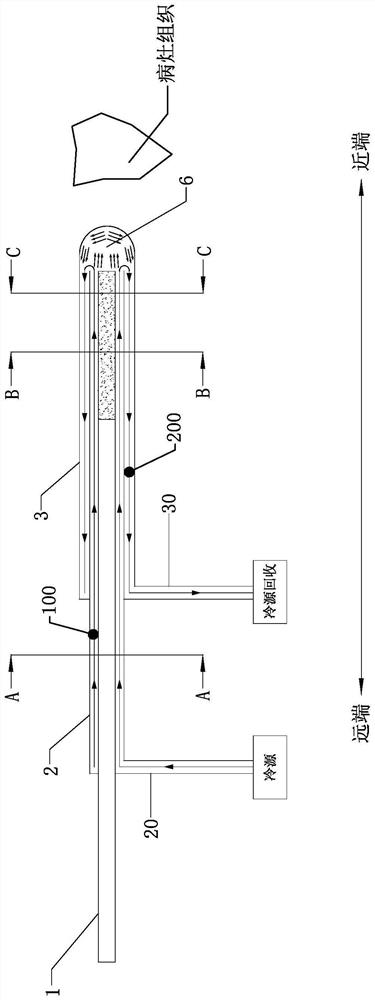

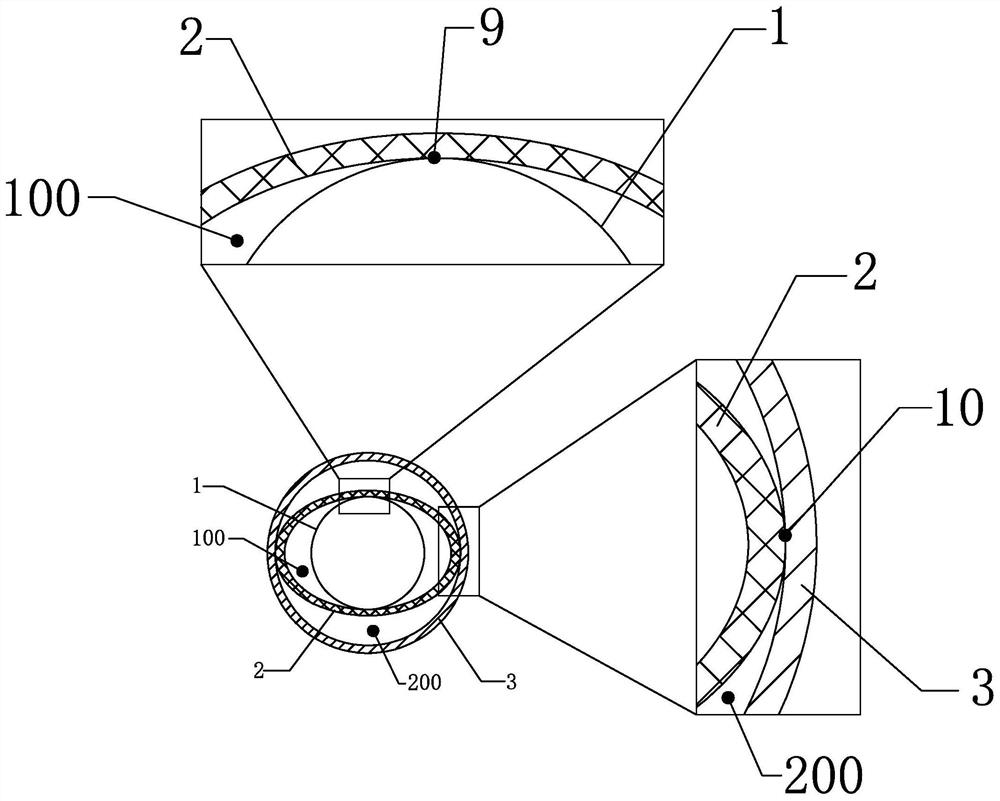

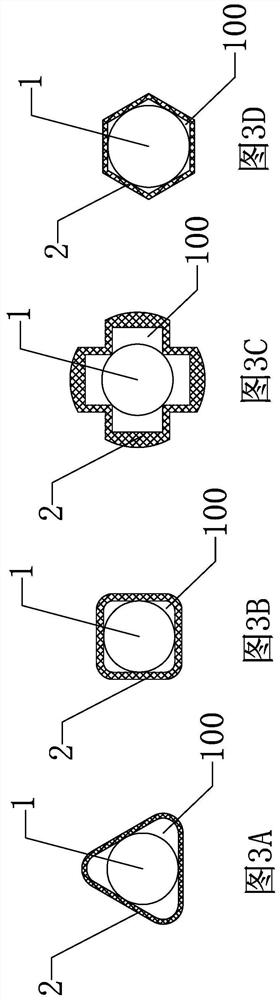

[0069] A cooling jacket proposed by the present invention, which sequentially includes a strip or tube to be cooled, an inner tube and an outer tube from the inside to the outside, the key lies in the strip or tube to be cooled, the inner tube The three are assembled and designed in a line contact or surface contact with the outer tube, or a mixed contact method of line contact and surface contact, and the coaxial self-support between the three can be realized without additional support structures; The multiple fluid cavities formed by this structure also avoid the cross-flow phenomenon of the fluid and ensure the cooling effect of the cooling jacket.

[0070] In the cooling jacket of the present invention, in magnetic resonance imaging-guided laser interstitial thermotherapy (LITT for short), the strip or tube to be cooled is an optical fiber. The following will take LITT technology as the creation background and describe the present invention in detail in conjunction with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com