Large-size sea urchin spherical magnesium carbonate trihydrate and porous magnesium oxide assembled by nanorod arrays and preparation method thereof

A technology of magnesium carbonate trihydrate and porous magnesium oxide, applied in magnesium oxide, magnesium carbonate and other directions, to achieve the effects of easy recovery and reprocessing, many surface active sites, and great application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

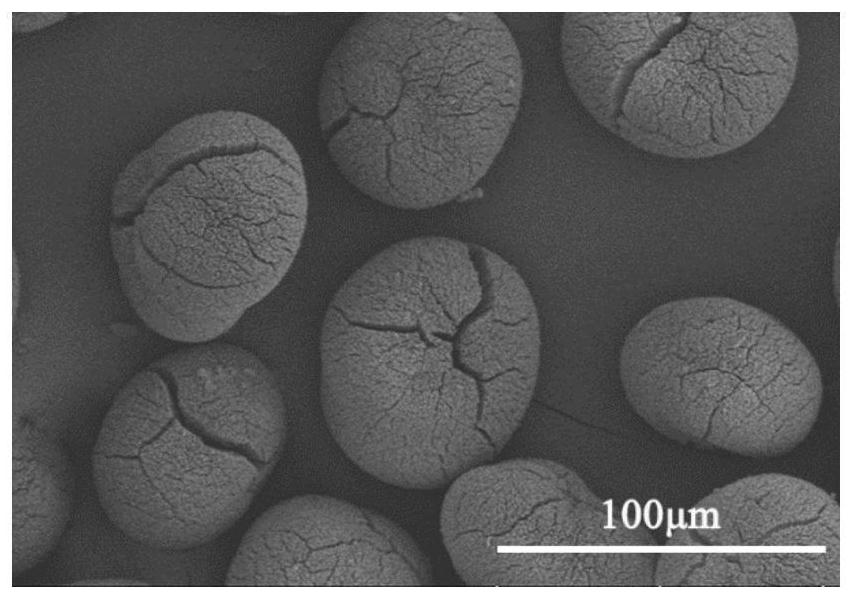

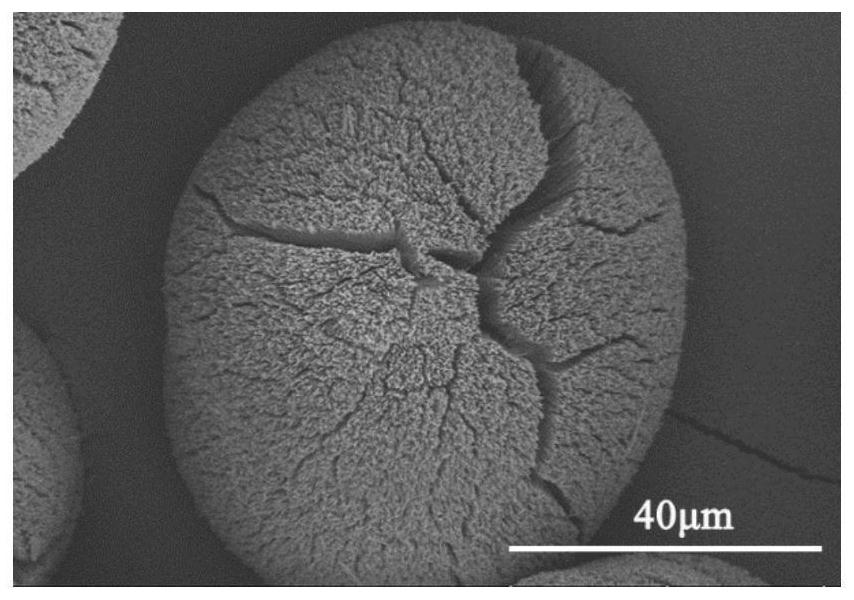

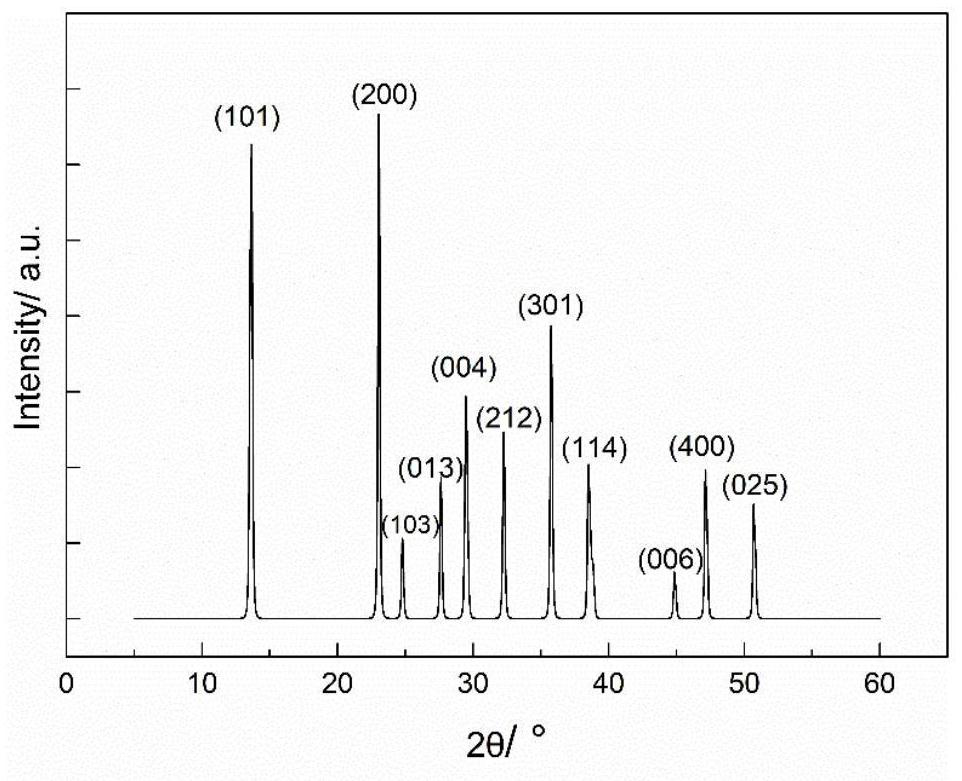

[0048] The large-size sea urchin spherical magnesium carbonate trihydrate and porous magnesium oxide assembled by nanorod arrays described in Example 1, the large-size sea urchin spherical magnesium carbonate trihydrate and porous magnesium oxide are assembled from nanorod arrays, and the large size The diameters of sea urchin spherical magnesium carbonate trihydrate and porous magnesium oxide are both 60-100 μm, and the diameter of nanorods is 70-140 nm. Porous magnesium oxide is obtained by pyrolysis and calcination of the above-mentioned large-sized sea urchin spherical magnesium carbonate trihydrate. Porous magnesium oxide It has a multi-level pore structure, that is, it contains a large number of micropores, mesopores and macropores at the same time, and the specific surface area is 157.1m 2 / g.

[0049] The preparation method of the large-size sea urchin spherical magnesium carbonate trihydrate and porous magnesium oxide assembled by nanorod arrays described in Example 1...

Embodiment 2

[0055] The large-size sea urchin spherical magnesium carbonate trihydrate and porous magnesium oxide assembled by nanorod arrays described in Example 2, the large-size sea urchin spherical magnesium carbonate trihydrate and porous magnesium oxide are assembled from nanorod arrays, and the large size The diameters of sea urchin spherical magnesium carbonate trihydrate and porous magnesium oxide are both 80-120 μm, and the diameter of nanorods is 90-180 nm. Porous magnesium oxide is obtained by pyrolysis and calcination of the above-mentioned large-sized sea urchin spherical magnesium carbonate trihydrate. Porous magnesium oxide It has a multi-level pore structure, that is, it contains a large number of micropores, mesopores and macropores at the same time, and the specific surface area is 163.2m 2 / g.

[0056] The preparation method of the large-size sea urchin spherical magnesium carbonate trihydrate and porous magnesium oxide assembled by nanorod arrays described in Example 2...

Embodiment 3

[0062] The large-size sea urchin spherical magnesium carbonate trihydrate and porous magnesium oxide assembled by nanorod arrays described in Example 3, the large-size sea urchin spherical magnesium carbonate trihydrate and porous magnesium oxide are assembled from nanorod arrays, and the large size The diameters of sea urchin spherical magnesium carbonate trihydrate and porous magnesium oxide are both 100-140 μm, and the diameter of nanorods is 80-130 nm. Porous magnesium oxide is obtained by pyrolysis and calcination of the above-mentioned large-sized sea urchin spherical magnesium carbonate trihydrate. It has a multi-level pore structure, that is, it contains a large number of micropores, mesopores and macropores at the same time, and the specific surface area is 123.3m 2 / g.

[0063] The preparation method of the large-size sea urchin spherical magnesium carbonate trihydrate and porous magnesium oxide assembled by nanorod arrays described in Example 3 consists of the follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com