High-hardness sound insulation brick prepared from foundry waste sand and preparation method thereof

A technology of casting waste sand and high hardness, which is used in the production, application, and ceramic products of ceramic materials, can solve the problems of corner powder, poor sound insulation effect, poor compactness, etc., to improve hardness and compactness, and improve sound insulation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

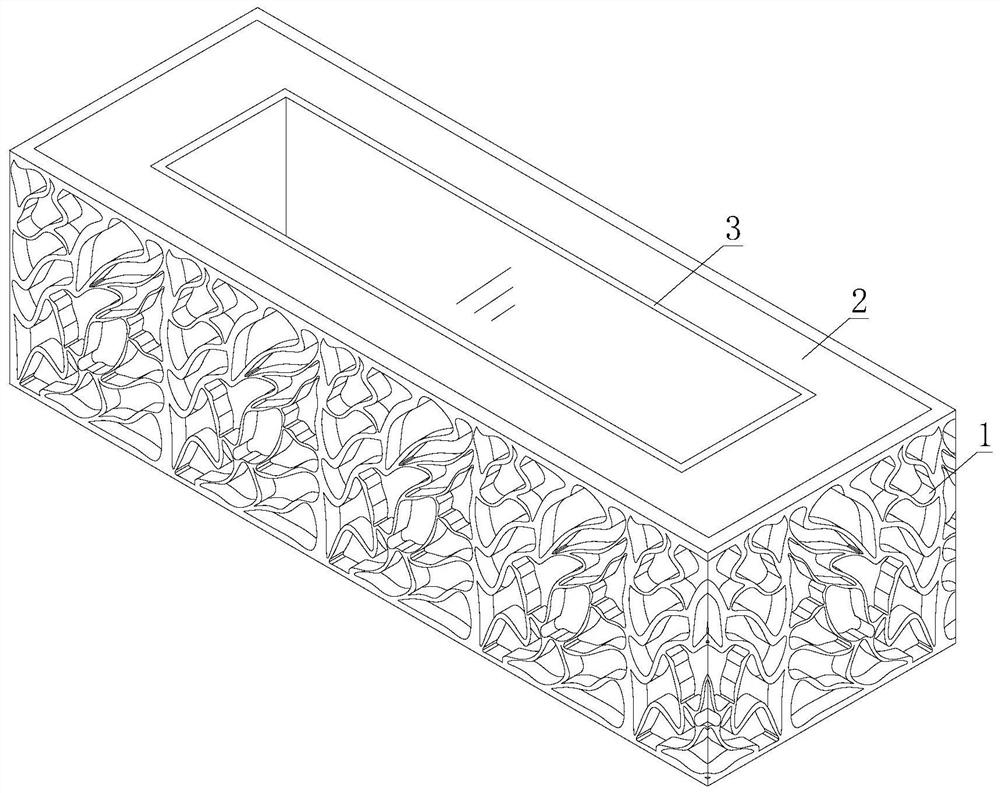

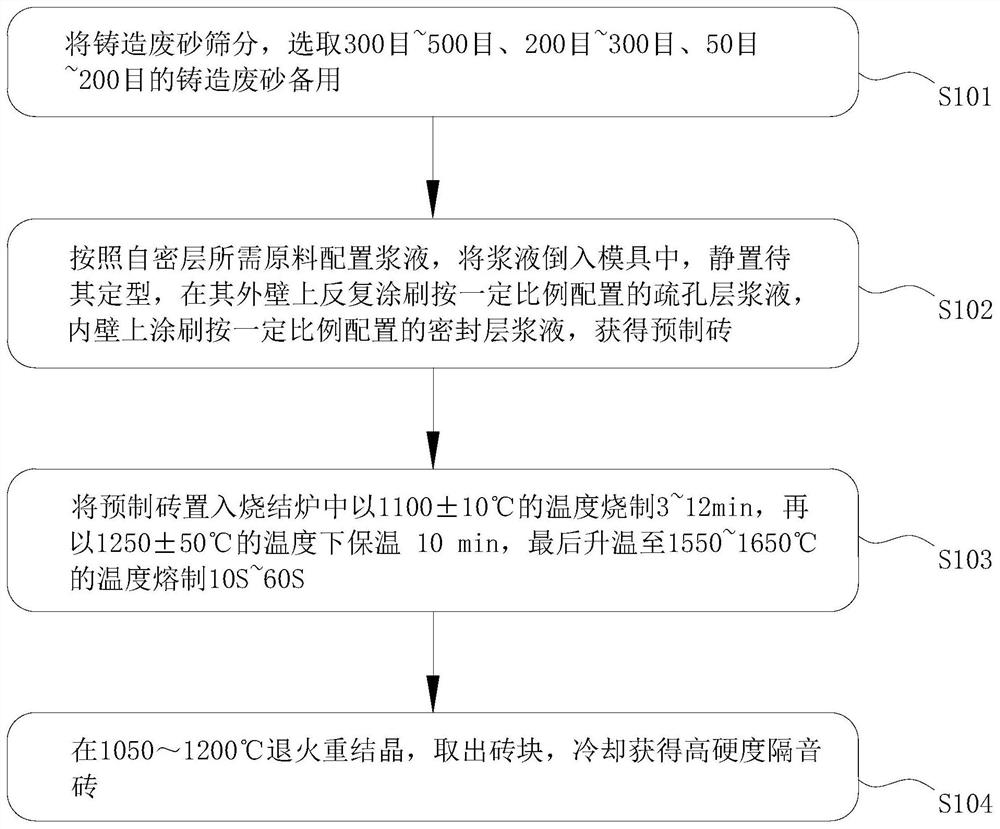

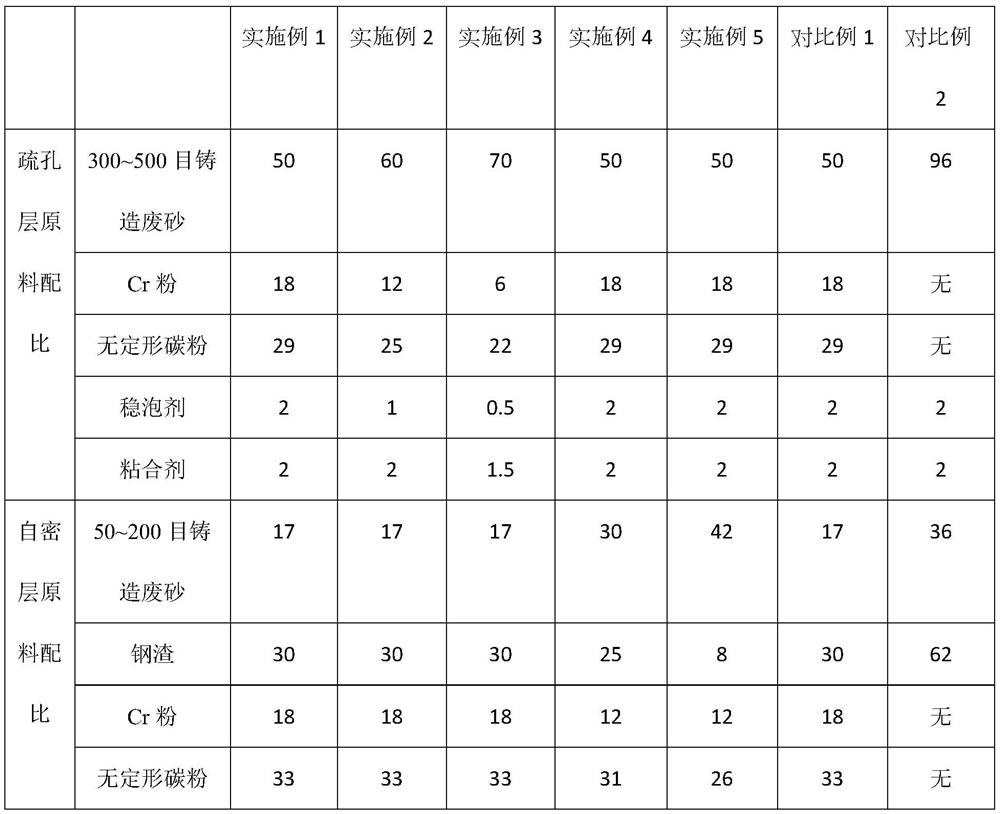

[0090] refer to figure 1 , a high-hardness sound-insulating brick produced by using foundry waste sand, including a porous layer 1, a self-dense layer 2 and a sealing layer 3, the self-dense layer 2 is a frame shape with both ends transparent, and a sealing layer is arranged inside it 3. There is a layer of porous layer 1 on the outside, and the ratio of the parts by weight of the raw materials used in the porous layer 1 is as follows:

[0091] 300 mesh to 500 mesh foundry waste sand 50;

[0092] Cr powder 18;

[0093] Amorphous carbon powder 29;

[0094] Foam stabilizer 2;

[0095] binder2;

[0096] Among them, the foundry waste sand is any one of water glass sand, resin sand and clay sand; wherein the foundry waste sand contains high-temperature gas-generating substances, such as sodium carbonate in water glass sand, organic components in resin sand, and clay sand. The coal components are all high-temperature gas-generating substances. The high-temperature gas-generatin...

Embodiment 2

[0113] The difference between the present embodiment and the first embodiment is only that the raw material ratio of the porous layer 1 is different, and the ratio of the parts by weight of the raw materials used in the porous layer 1 is as follows:

[0114] 300 mesh to 500 mesh foundry waste sand 60;

[0115] Cr powder 12;

[0116] Amorphous carbon powder 25;

[0117] Foam stabilizer 1;

[0118] binder2;

[0119] Among them, the foundry waste sand is any one of water glass sand, resin sand and clay sand; the binder is water glass, that is, the mixture particles of sodium silicate and potassium silicate; the foam stabilizer is polyacrylamide, polyethylene Any one or more of alcohol, protein, polypeptide, starch, cellulose and silicone amide.

Embodiment 3

[0121] The difference between the present embodiment and the first embodiment is only that the raw material ratio of the porous layer 1 is different, and the ratio of the parts by weight of the raw materials used in the porous layer 1 is as follows:

[0122] 300 mesh to 500 mesh foundry waste sand 70;

[0123] Cr powder 6;

[0124] Amorphous carbon powder 22;

[0125] Foam stabilizer 0.5;

[0126] binder 1.5;

[0127] Among them, the foundry waste sand is any one of water glass sand, resin sand and clay sand; the binder is water glass, that is, the mixture particles of sodium silicate and potassium silicate; the foam stabilizer is polyacrylamide, polyethylene Any one or more of alcohol, protein, polypeptide, starch, cellulose and silicone amide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com