Preparing method of nickel-silicon alloy cast ingot

A technology of nickel-silicon alloy and ingot casting, which is applied in the field of preparation of nickel-silicon alloy ingot, can solve the problems of low silicon content, large silicon volatilization and loss, and poor distribution uniformity of nickel-silicon alloy ingot, and achieve accurate nickel-silicon content , low production cost and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

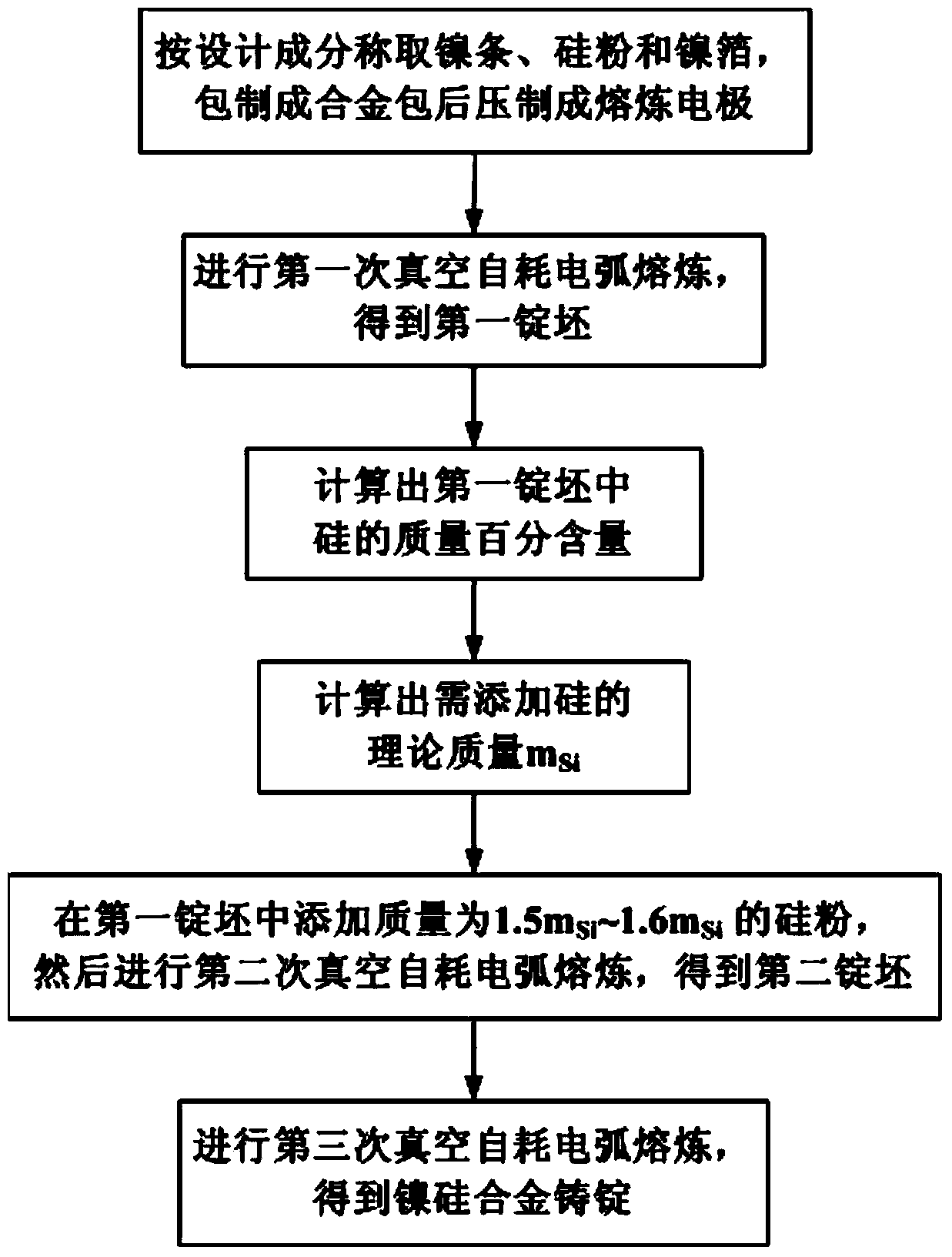

[0023] combine figure 1 , Preparation of Ni-11.15Si nickel-silicon alloy ingot:

[0024] Step 1. According to the design composition of Ni-11.15Si nickel-silicon alloy ingot to be prepared (that is, the mass ratio of nickel to silicon is 88.85:11.15, and the mass percentage of silicon is y=11.15%), weigh nickel strips, silicon powder and nickel Foil, and then mix the nickel strip and silicon powder evenly and cover it with nickel foil to make an alloy bag, and then use a hydraulic press to press the alloy bag to obtain a smelting electrode;

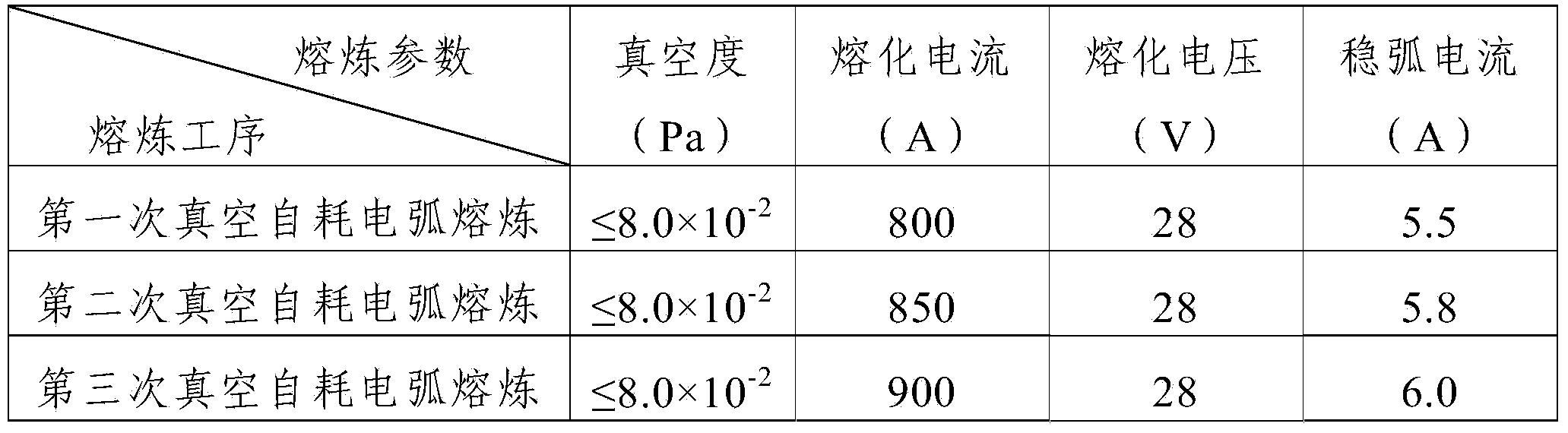

[0025] Step 2. Place the smelting electrode described in step 1 in a vacuum consumable arc furnace for the first vacuum consumable arc melting. After water cooling, remove the surface scale to obtain a cross-sectional diameter of Ф50 mm and a mass of m NiSi-1 =3000g of the first billet; the melting parameters of the first vacuum consumable arc melting are shown in Table 1;

[0026] Step 3, using the Archimedes principle to measure the d...

Embodiment 2

[0034] combine figure 1 , Preparation of Ni-10Si nickel-silicon alloy ingot:

[0035] Step 1. According to the design composition of the Ni-10Si nickel-silicon alloy ingot to be prepared (that is, the mass ratio of nickel to silicon is 90:10, and the mass percentage of silicon is y=10%), weigh nickel strips, silicon powder and nickel foil , and then mix the nickel strip and silicon powder evenly and cover it with nickel foil to make an alloy bag, and then use a hydraulic press to press the alloy bag to obtain a smelting electrode;

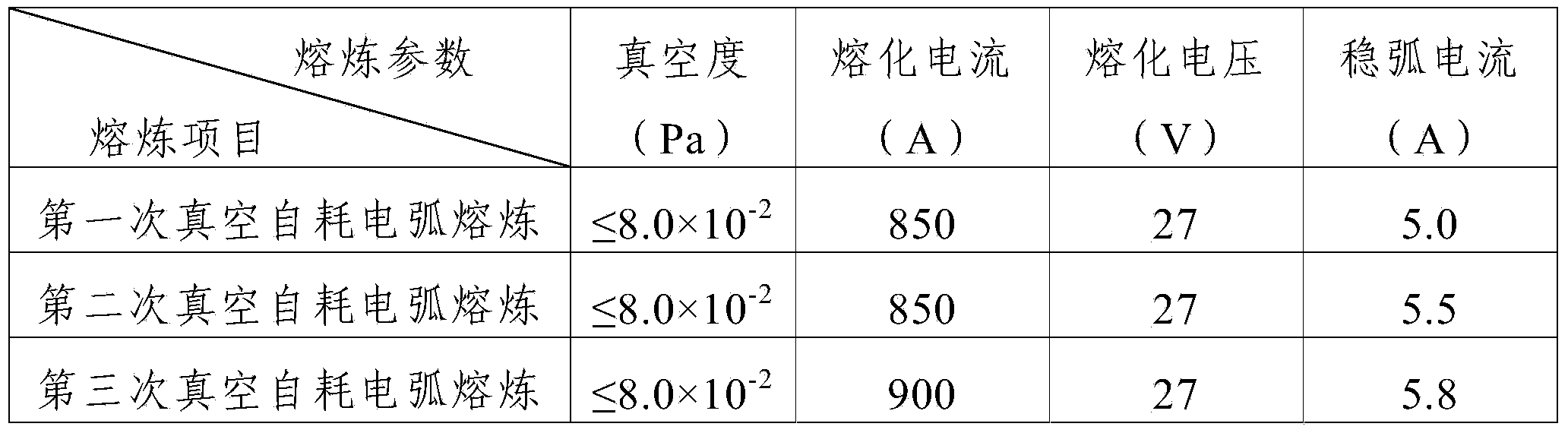

[0036] Step 2. Place the smelting electrode described in step 1 in a vacuum consumable arc furnace for the first vacuum consumable arc melting. After water cooling, remove the surface scale to obtain a cross-sectional diameter of Ф60 mm and a mass of m NiSi-1 =4000g of the first billet; the melting parameters of the first vacuum consumable arc melting are shown in Table 2;

[0037] Step 3, using the Archimedes principle to measure the density ρ of ...

Embodiment 3

[0045] combine figure 1 , Preparation of Ni-15Si nickel-silicon alloy ingot:

[0046] Step 1. Weigh nickel strips, silicon powder and nickel foil according to the design composition of the Ni-15Si nickel-silicon alloy ingot to be prepared (that is, the mass ratio of nickel to silicon is 85:15, and the mass percentage of silicon is y=15%) , and then mix the nickel strip and silicon powder evenly and cover it with nickel foil to make an alloy bag, and then use a hydraulic press to press the alloy bag to obtain a smelting electrode;

[0047] Step 2. Place the smelting electrode described in step 1 in a vacuum consumable arc furnace for the first vacuum consumable arc melting. After water cooling, remove the surface scale to obtain a cross-sectional diameter of Ф30mm and a mass of m NiSi-1 =2000g of the first billet; the melting parameters of the first vacuum consumable arc melting are shown in Table 3;

[0048] Step 3, using the Archimedes principle to measure the density ρ of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com