Preparation method and preparation device of trichloroacetyl chloride

A technology of trichloroacetyl chloride and preparation device, which is applied in the directions of acid halide preparation, organic compound preparation, feeding device, etc., can solve the problems of complex production process of trichloroacetyl chloride preparation device, etc., and achieves the solution of complex and simplified production process. The effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

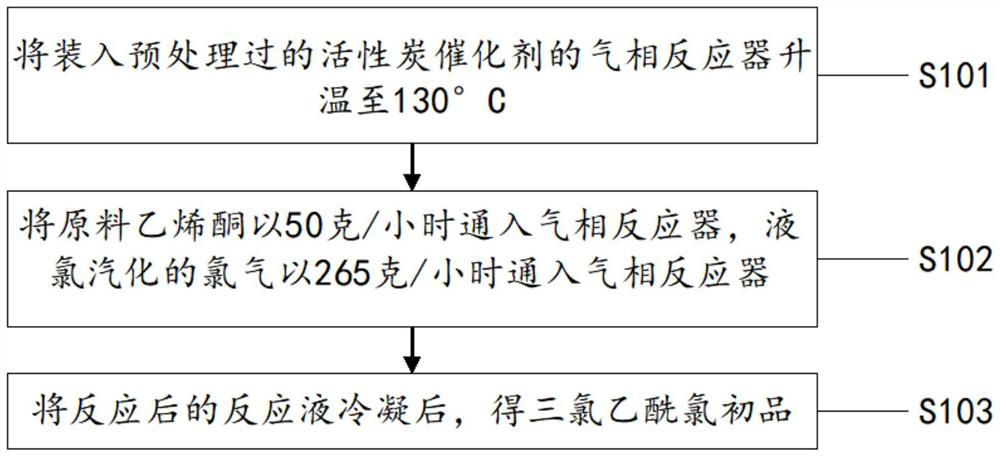

[0025] Example 1, see figure 1 , the invention provides a kind of preparation method of trichloroacetyl chloride, comprising:

[0026] S101, the temperature of the gas phase reactor 6 loaded with the pretreated activated carbon catalyst is raised to 130° C.;

[0027] The pretreatment method of activated carbon is to add preferred activated carbon into a pipe with a diameter of 25-100MM, and slowly heat it to 150°C under vacuum until no water is released. Nitrogen was introduced to normal pressure, and then chlorine gas was slowly introduced at 150°C for activation until the temperature of the activated carbon layer was stable, and then the temperature was lowered.

[0028] S102, the raw material ketene is passed into the gas phase reactor 6 at 50 g / hour, and the chlorine gas vaporized by liquid chlorine is passed into the gas phase reactor 6 at 265 g / hour;

[0029] Chlorine vaporized by ketene and liquid chlorine are both calibrated by flowmeters and then controlled for mete...

Embodiment 2

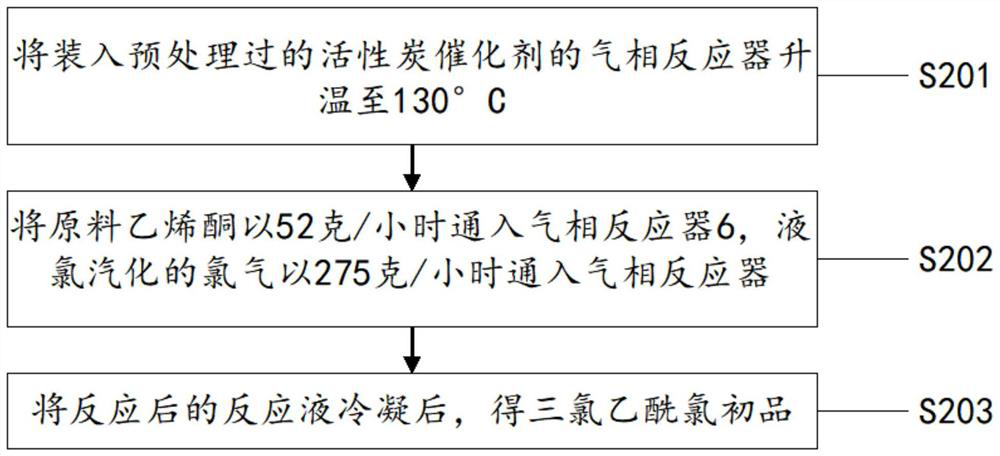

[0032] Example 2, see figure 2 , the invention provides a kind of preparation method of trichloroacetyl chloride, comprising:

[0033] S201, the temperature of the gas phase reactor 6 loaded with the pretreated activated carbon catalyst is raised to 130° C.;

[0034] The pretreatment method of activated carbon is to add preferred activated carbon into a pipe with a diameter of 25-100MM, and slowly heat it to 150°C under vacuum until no water is released. Nitrogen was introduced to normal pressure, and then chlorine gas was slowly introduced at 150°C for activation until the temperature of the activated carbon layer was stable, and then the temperature was lowered.

[0035] S202, raw material vinyl ketone is passed into gas-phase reactor 6 with 52 grams / hour, and the chlorine gas of liquid chlorine vaporization is passed into gas-phase reactor 6 with 275 grams / hour;

[0036] Chlorine vaporized by ketene and liquid chlorine are both calibrated by flowmeters and then controlle...

Embodiment 3

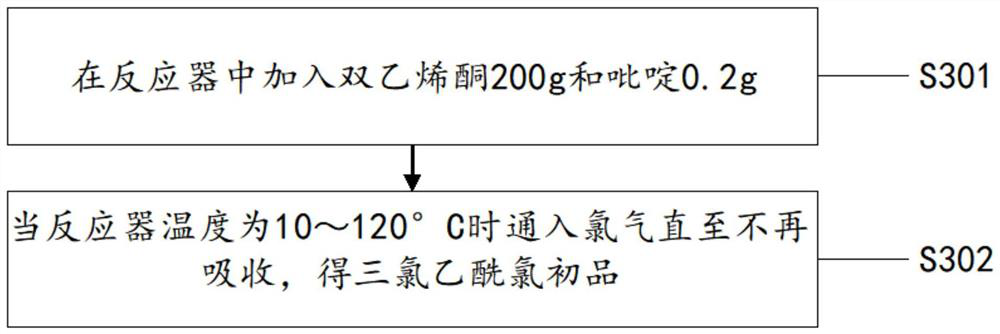

[0039] Example 3, see image 3 , the invention provides a kind of preparation method of trichloroacetyl chloride, comprising:

[0040] S301. Add 200 g of diketene and 0.2 g of pyridine into the reactor;

[0041] The reactor is 100ml.

[0042] S302. When the temperature of the reactor is 10-120° C., feed chlorine gas until it is no longer absorbed to obtain the primary product of trichloroacetyl chloride.

[0043] About 1100g of chlorine gas was introduced, and the content of the initial product was trichloroacetyl chloride: 96.7%, monochloroacetyl chloride: 0.8%, dichloroacetyl chloride: 0.5%, carbon tetrachloride: 0.7% and others: 1.3%.

[0044] see Figure 4, the present invention also provides a preparation device for trichloroacetyl chloride, comprising a ketene intake pipe 1, a buffer tank 3, a vaporizer 2, a gas phase reactor 6, a first chlorine gas intake pipe 16, a condenser 7, a receiving tank 8, Absorption mechanism 9, hydrochloric acid tank 10, delivery mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com